The Analytical Laboratory team at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently began radiological testing to calibrate laboratory instruments and confirm procedures, a significant step toward future waste-treatment operations.

Office of Environmental Management

April 30, 2024RICHLAND, Wash. — The Analytical Laboratory team at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently began radiological testing to calibrate laboratory instruments and confirm procedures, a significant step toward future waste-treatment operations.

“The testing will validate the lab’s chemical and radiological safety measures,” said Mat Irwin, acting assistant manager for the WTP project. “The team will demonstrate that instruments are qualified to perform analyses of radioactive waste samples during future waste-treatment operations.”

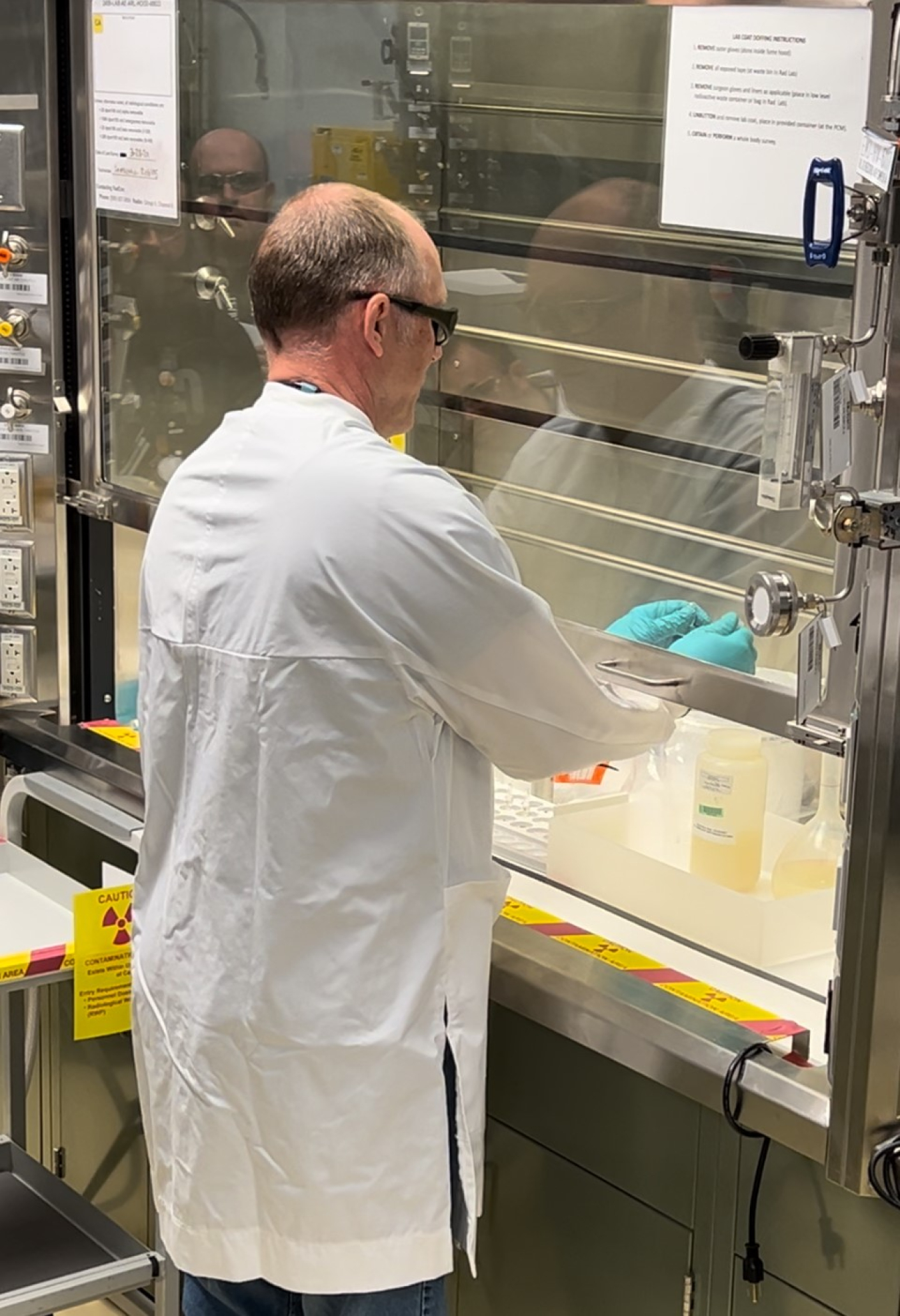

Chemist Brian Anderson opens the first vial of radioactive liquid inside a protective fume hood in the Analytical Laboratory at the Hanford Site’s Waste Treatment and Immobilization Plant.

WTP staff completed a comprehensive review of lab systems, teams and processes to ensure readiness for the radiological testing prior to opening the first ever vial of radioactive solution in the lab.

“Our team confirmed all radiological control instruments were fully operational and demonstrated our chemists’ proficiency in radiological and chemical safety practices," said Jessica Coughlin, laboratory analytical manager for Hanford subcontractor Waste Treatment Completion Company.

During future plant operations, workers will immobilize in glass millions of gallons of radioactive and chemical waste from large underground tanks at Hanford. WTP’s Analytical Laboratory staff will analyze samples of the waste as it is transferred to WTP. These analyses will be used to determine the correct “recipe” of glass-forming materials to mix with the waste before it is transferred into one of the plant’s two 300-ton glass melters for vitrification.

-Contributor: Tyler Oates

To receive the latest news and updates about the Office of Environment Management, submit your e-mail address.