Photo

Caption

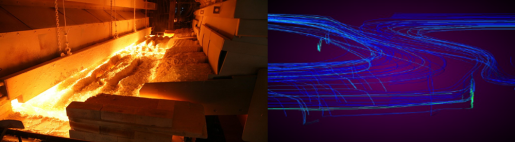

Glass manufacturers use high-performance computing to enable machine learning tools that can detect and correct for variations in glass furnaces in real-time.

Credit

Vitro Glass / LLNL

Photo

Caption

An engineer monitors a feed control system for a new, energy efficient pilot process for producing ethylene, one of the most energy-intensive and commonly manufactured chemicals.

Credit

EcoCatalytic

Photo

Caption

More than 1,400 new robots are a part of the body shop at General Motors’ Arlington Assembly plant. This facility was among the 25 GM plants that achieved DOE’s 50001 Ready status for implementing energy management systems.

Credit

GM Archive Photo

Photo

Caption

The Enhanced Preparation for Intelligent Cybermanufacturing Systems (EPICS) program at Georgia Tech prototypes a face shield frame in response to COVID-19. EPICS prepares students for the next-generation of manufacturing careers.

Credit

Georgia Tech

Photo

Caption

Carbon Fiber Technology Facility Director Merlin Theodore holds material meeting N95 specifications produced at the facility. The team developed process parameters for manufacturers to recalibrate melt-blown machines to address shortages.

Credit

ORNL

Photo

Caption

Researchers at the Manufacturing Demonstration Facility use metal additive manufacturing to create toolsets for reusable masks in response to COVID-19.

Credit

ORNL

Photo

Caption

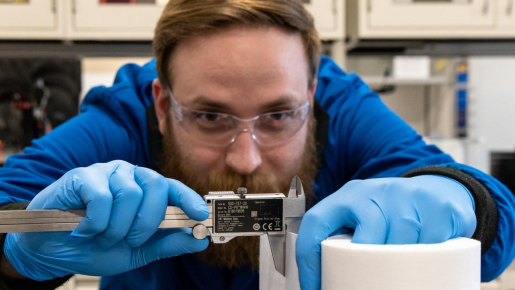

Kevin O’Connor conducts R&D for technology that will improve energy storage performance and enable more compact devices with higher reliability through DOE’s Lab-Embedded Entrepreneurship Program node at ANL.

Credit

ANL

Photo

Caption

NEW Water achieved their Better Plants Challenge energy intensity reduction goal by implementing their Resource Recovery and Electrical Energy project, which replaced an existing solids handling facility and installing two anaerobic digesters to capture methane gas and produce electricity.

Credit

N/A

Photo

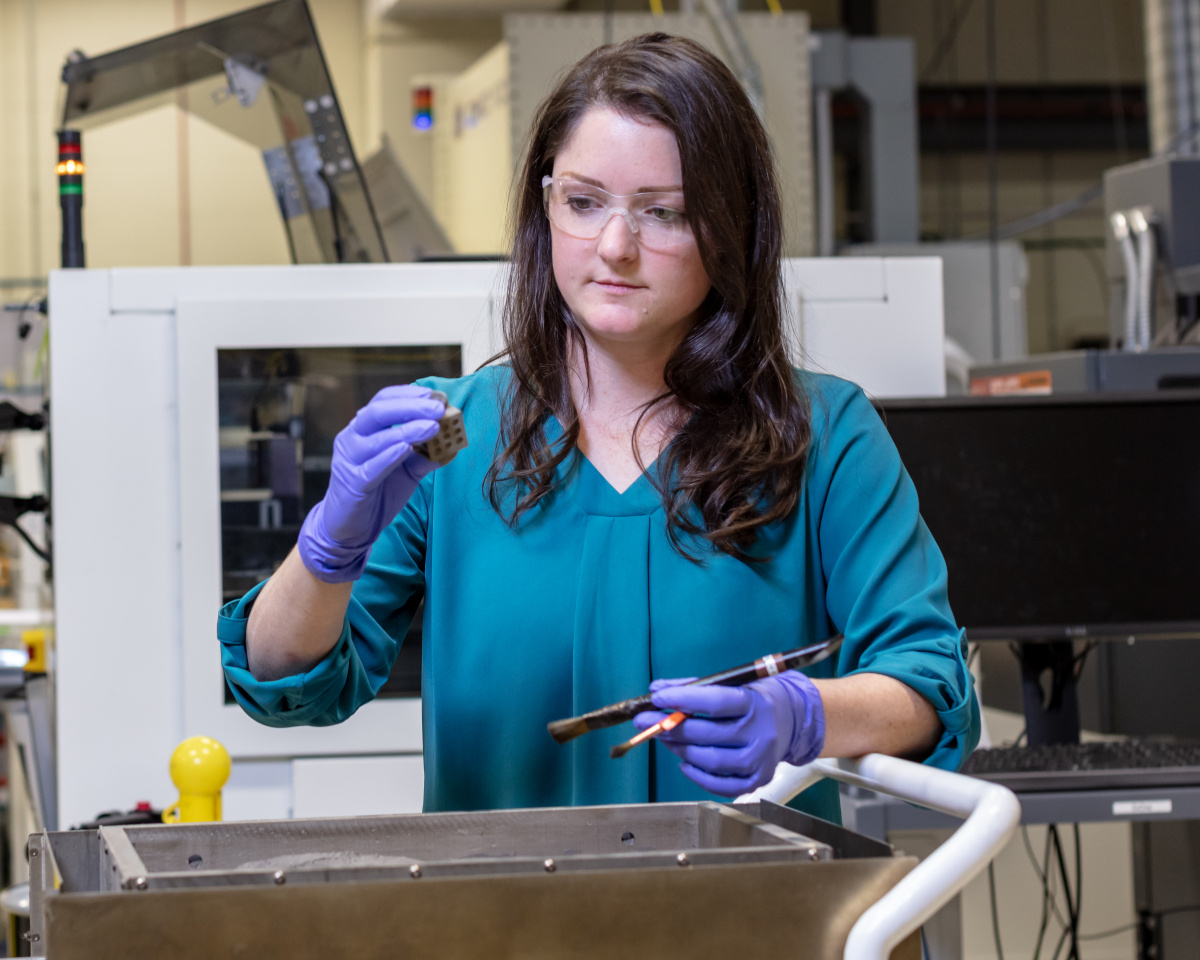

Caption

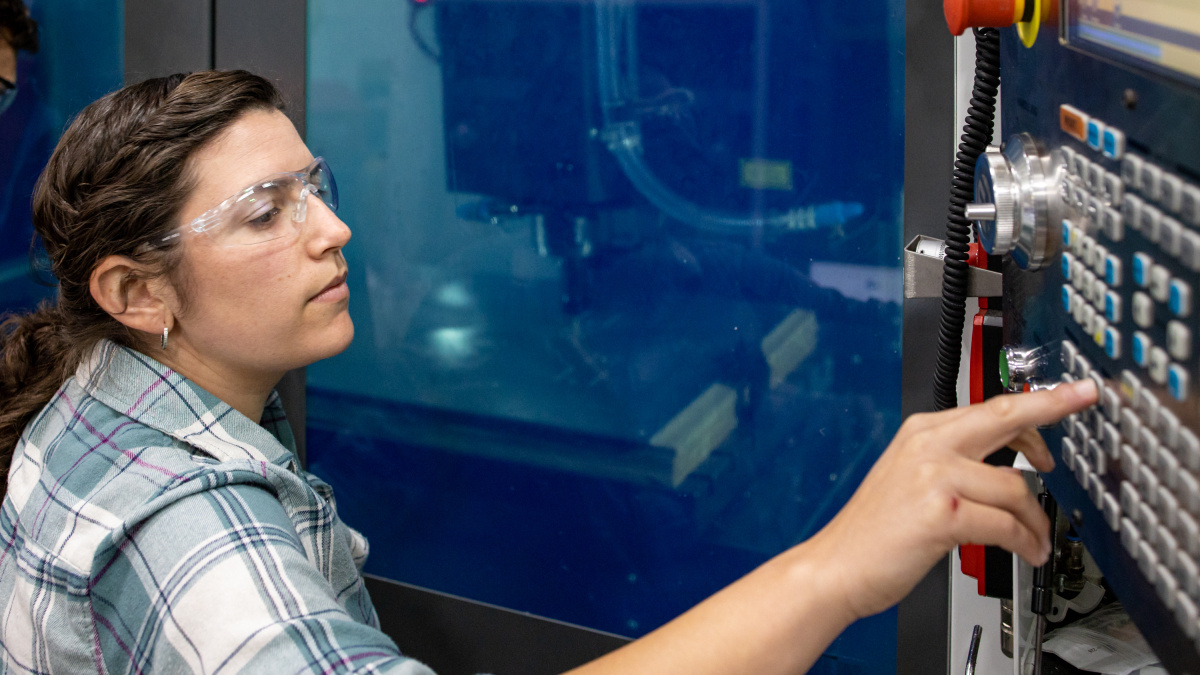

Emma Betters, a machining researcher at ORNL, is part of the MDF’s moonshot initiative to design a new process for building machine tools in the U.S., utilizing 3D printing and concrete.

Credit

ONRL

Photo

Caption

Brian Post, a large-scale additive manufacturing research at ORNL, designed SkyBAAM, a low-cost, cable-driven field deployable additive manufacturing system that uses low embodied carbon concrete.

Credit

ORNL

Photo

Caption

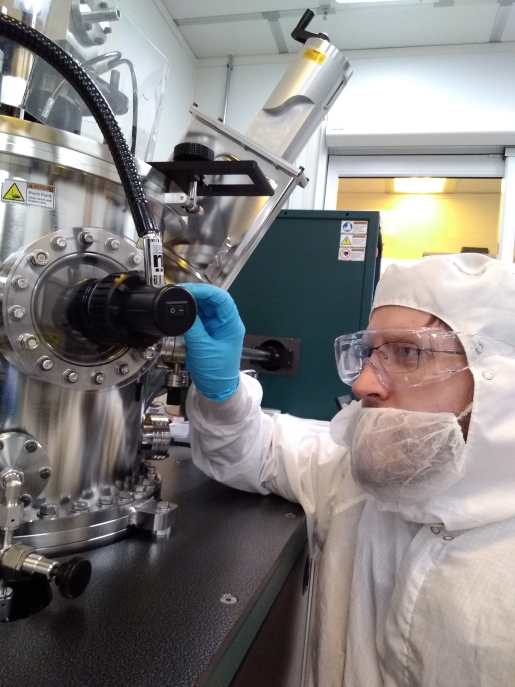

Amy Elliott, a robotics and automation researcher at ORNL, uses binder 3D printing, a technique that can produce objects in shapes and out of materials that are typically difficult to print by fusing together layers of metal powder spread across a surface.

Credit

ORNL

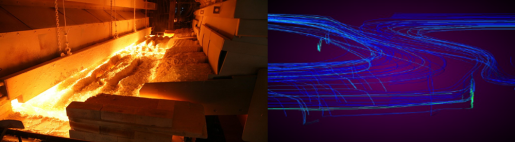

Photo

Caption

Glass manufacturers use high-performance computing to enable machine learning tools that can detect and correct for variations in glass furnaces in real-time.

Credit

Vitro Glass / LLNL

Glass manufacturers use high-performance computing to enable machine learning tools that can detect and correct for variations in glass furnaces in real-time.

Vitro Glass / LLNL

October 14, 2025