Project Name: Progression to Compatibility Evaluations in Flowing Molten Salts

Funding Opportunity: Generation 3 Concentrating Solar Power Systems Lab Call

SETO Subprogram: Concentrating Solar-Thermal Power

Location: Oak Ridge, TN

SETO Award Amount: $1,000,000

Awardee Cost Share: N/A

This project will test molten salts to measure their corrosion in structural alloys, such as stainless steel and high-nickel-content superalloys, being considered for use in concentrating solar power (CSP) plants. The compatibility of the salts and alloys is key to getting molten salts to act as heat transfer fluids in high-temperature CSP systems. The project team will first identify combinations of salts and alloys that are compatible at temperatures above 700° Celsius, then evaluate them at high temperatures and with flowing salt. From there, the researchers can investigate ways to prevent corrosion or the accuracy of corrosion-tracking sensors.

APPROACH

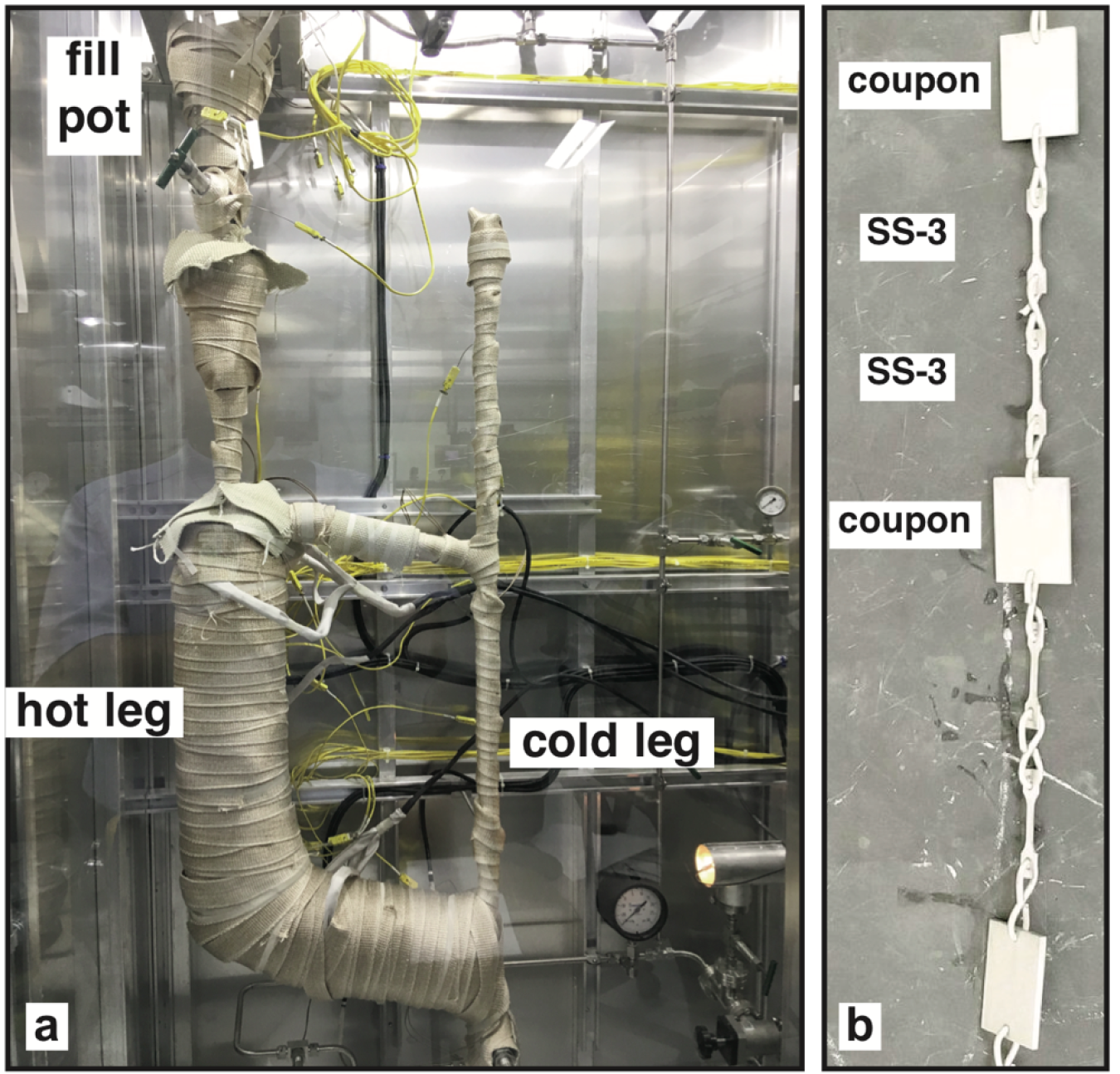

To determine compatibility between molten salts and alloys, the team will use a thermal convection loop (TCL), a circular piece of equipment heated on one side to create a flow of molten salt. Flowing molten salt increases the potential for chemical reactions as new salt is continually introduced, which is the reason a TCL is used instead of a static vessel: It more accurately mimics the flowing conditions in a real CSP system. By running the TCL continuously for hundreds of hours at temperatures above 700°C, the researchers will be able to accurately characterize how salt affects the alloys.

INNOVATION

When the team determines the corrosion rates of the alloys and compares them with the target rates, the results will measure the effectiveness of the salt-purification methods, as well as data about molten salt compatibility and the design, fabrication, and operation of thermal loop experiments. This comparison can be used to evaluate different alloy-salt combinations to determine whether they can be used in future CSP designs.