Around the Nuclear Security Enterprise, researchers have found new ways to cast metal, create one-way “mirrors,” and revolutionize 3D printing – all using microwaves.

National Nuclear Security Administration

June 16, 2025NNSA uses the entire spectrum to complete its missions and develop new science and technology for tomorrow. Around the Nuclear Security Enterprise, researchers have found new ways to cast metal, create one-way “mirrors,” and revolutionize 3D printing – all using microwaves.

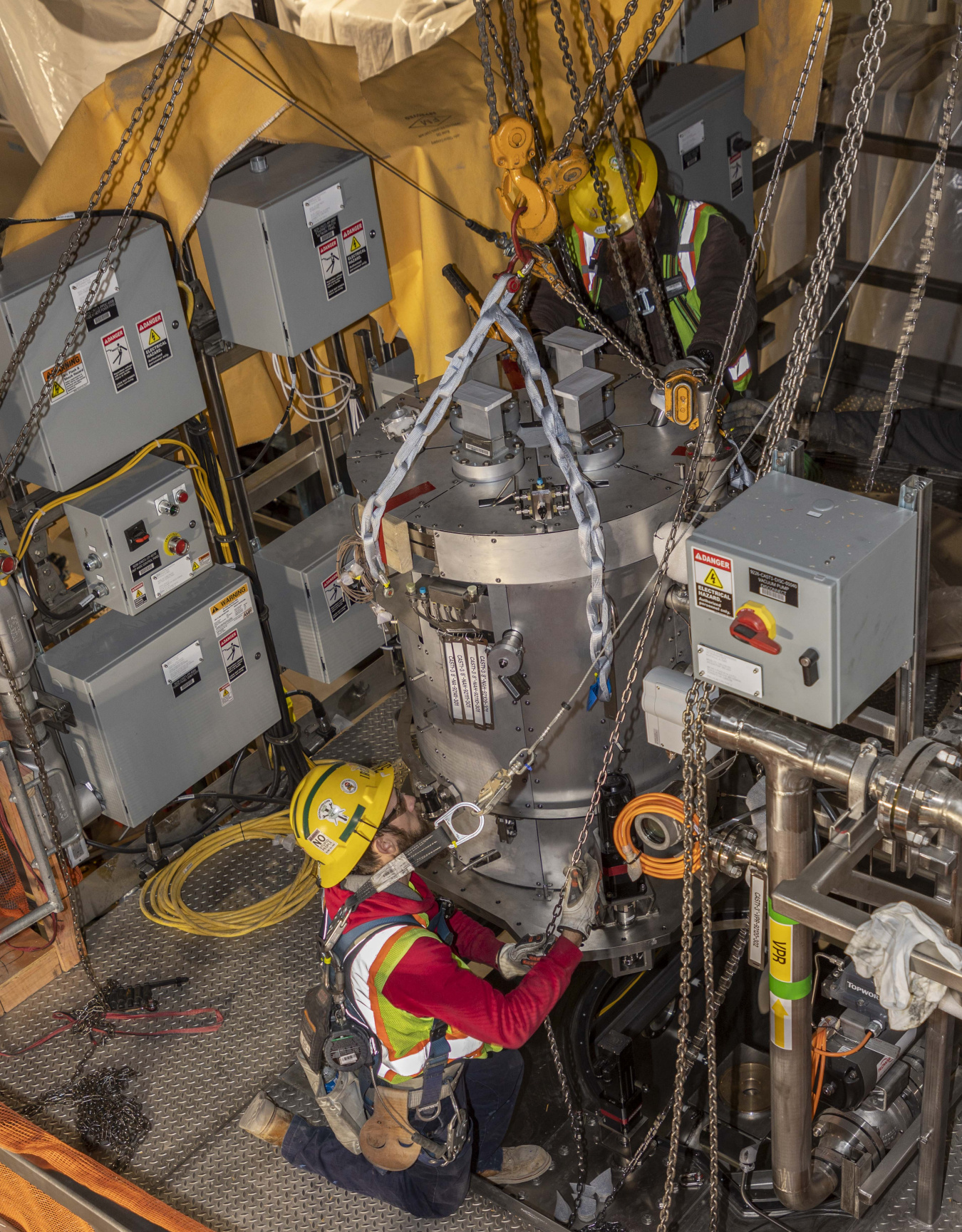

Casting metal more efficiently

Did you know that under the right circumstances, it’s possible to melt metal with microwaves?

Teams at Y-12 National Security Complex have taken that concept to the next level, developing a technology that uses microwave energy to melt and cast metal parts into shape. As construction continues at the Uranium Processing Facility, Y-12 has integrated microwave casting furnaces into the production line that will someday produce parts for the nuclear stockpile.

The method used now, vacuum-induction melting furnaces, is very different. In these furnaces, broken uranium metal pieces are placed into a crucible and magnetic fields heat the vessel up (the process is similar to the technology used in an induction stove). The uranium melts and the molten metal is poured into casts.

By using modern microwave technology, the process is faster, more cost-effective and energy efficient, and takes up less space.

Y-12 has studied this technology thoroughly and as it matures, there could be all kinds of applications for it, including heat-treating metals, joining components together, manufacturing specialty chemicals, or even nanotechnology manufacturing.

A 3D-printing marvel

Lawrence Livermore National Laboratory (LLNL) researchers have found that microwaves open a whole new world of 3D printing.

Traditional 3D printing techniques, while amazing, are often time consuming and limited in the kinds of materials they can use. But a LLNL team, led by staff scientists Saptarshi Mukherjee and Johanna Schwartz, has pioneered Microwave Volumetric Additive Manufacturing that allows the use of a wide range of materials.

The breakthrough involves the resin-heating process. During this phase, researchers introduced microwaves, which penetrate more deeply into the material. This allows both opaque and transparent resins to cure and harden to full strength more quickly. It even works on plastic resins that are loaded with additives.

Because it is scalable, the technique could allow 3D-printed parts to be made bigger and more complex in the future. It has potential uses in national security and industries like aerospace, automotive, and healthcare. The technology can currently print objects up to about 2 inches, but according to the team could scale up to 36-inch-plus structures in the future.

“A whole new world of printing materials becomes possible,” said materials chemist Johanna Schwartz. “With the unique opportunity to expand the definition of ‘printable,’ … this is a whole new printing space, and our ongoing progress is extremely exciting.”

LLNL is working with partners Sandia National Laboratories and Idaho National Laboratory to further develop the technology. You can read more about the research here.

Creating microwave “mirrors”

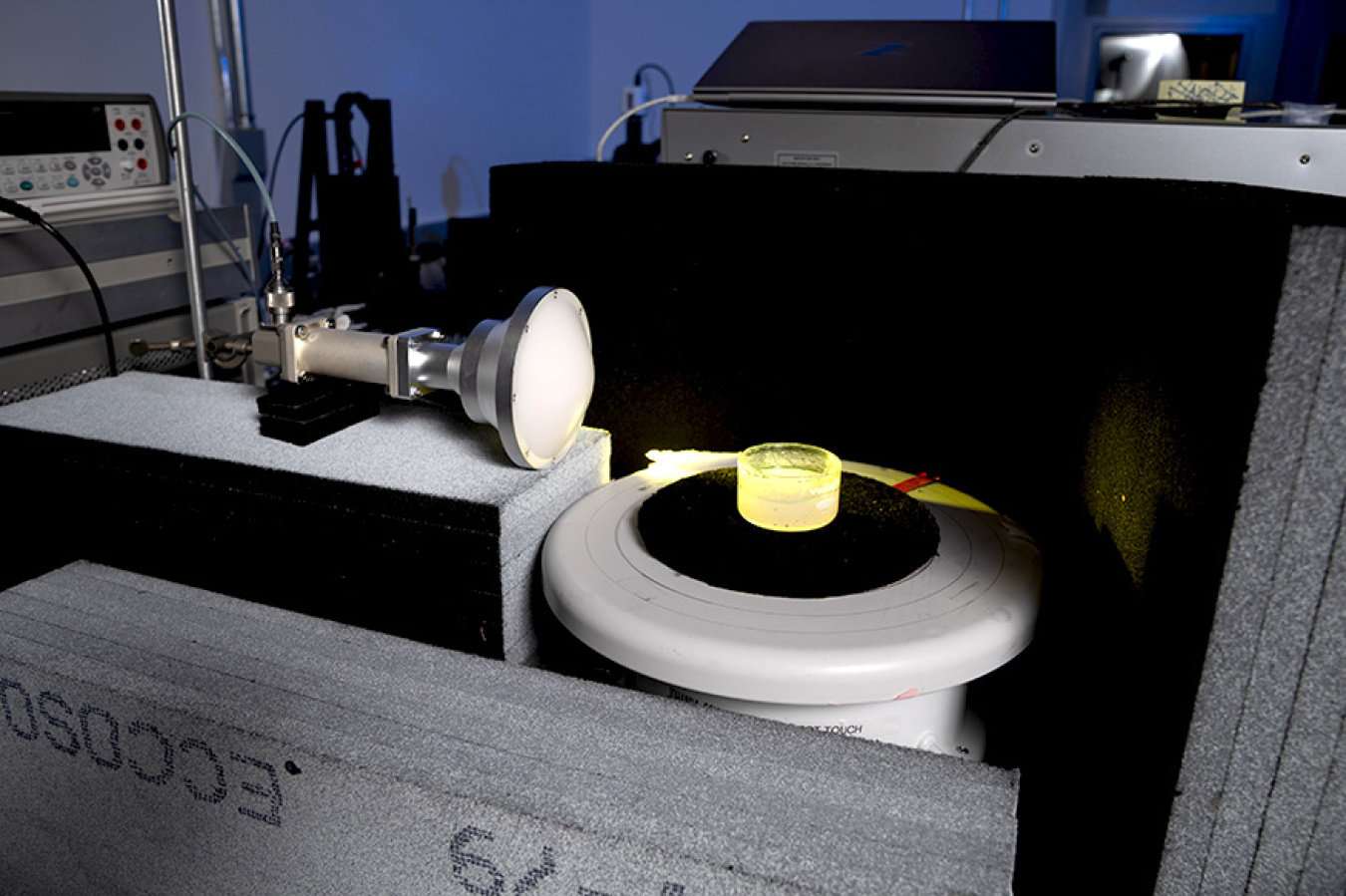

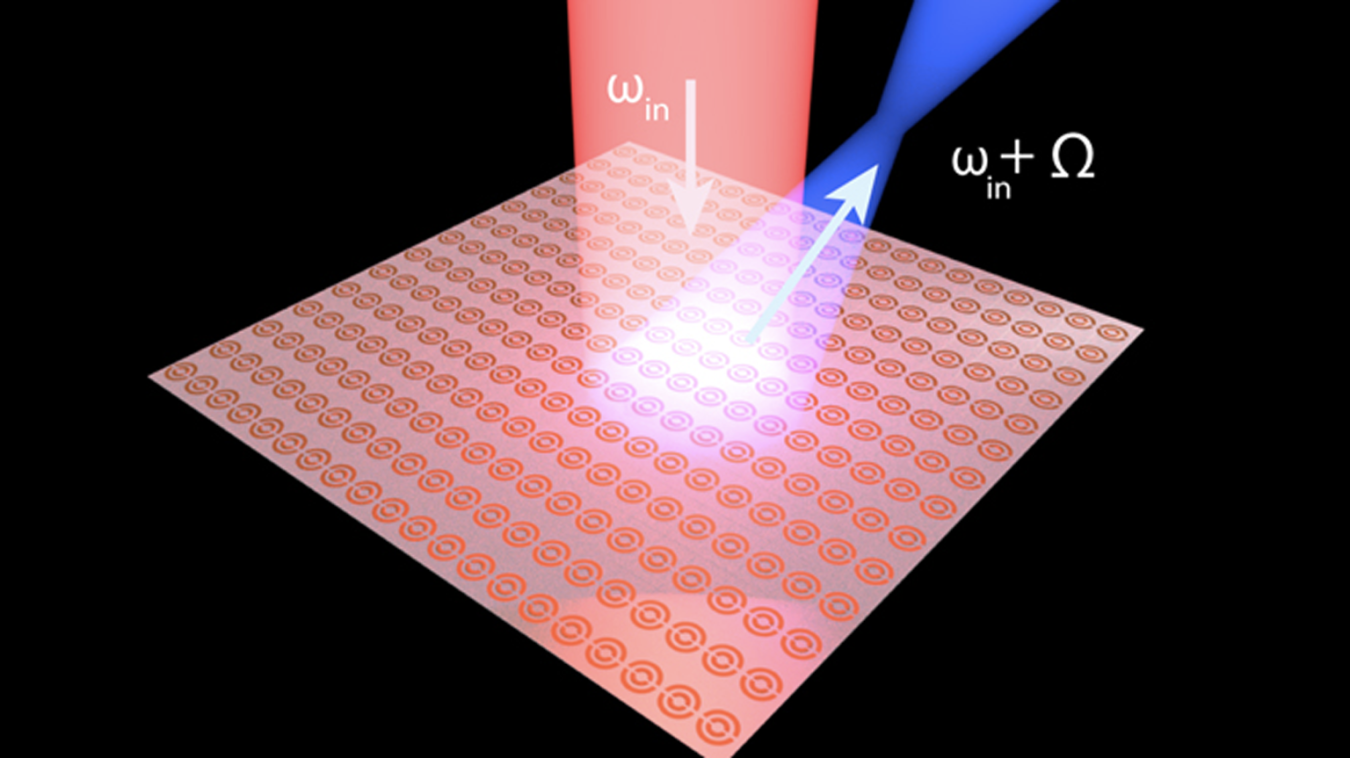

At Los Alamos National Laboratory, researchers have reinvented the mirror, at least for microwaves.

They developed a special microwave antenna called a reflector, that is made up of finely structured electronic components. By applying electric signals to individual components, the 2D reflector can perform like a 3D antenna, and in some cases do things no conventional antenna could do.

Most reflectors are reciprocal: in the case of a bathroom mirror, for example, if you can see someone reflected in it, they can see you too. The new reflector design “breaks” reciprocity, effectively turning it into a one-way mirror.

It has the potential to replace the familiar microwave antennas and microwave horns we see on rooftops and cell towers with flat panels that are compact, versatile, and better adapted for modern communication. It also has applications in national security. Miniature versions could improve chip-based circuitry by ensuring that signals go only to the intended components and don’t lead to inadvertent signals in other parts of the circuit, a problem that chip designers often worry about.

Research at NNSA spans the entire electromagnetic spectrum – take a look at findings at other frequencies and how they help further the missions of the Nuclear Security Enterprise.