With support from DOE's Accident Tolerant Fuel Program, one company is pioneering the use of silicon carbide to create nuclear fuel cladding that's tougher than ever.

July 9, 2024

Could something that's been used for many years to make cutting tools and high-power electrical systems revolutionize nuclear fuels?

General Atomics - Electromagnetic Systems (GA-EMS) thinks it can.

Because of its hardness and ability to withstand extremely high temperatures, silicon carbide has been used for industrial purposes for decades.

But now for the first time, with support from Department of Energy’s (DOE) Accident Tolerant Fuel Program, GA-EMS has successfully created silicon carbide nuclear fuel cladding tubes that can withstand extreme temperatures and could completely transform the way industry makes future fuel.

Here’s what you need to know.

What is Fuel Cladding, Anyway?

You may be asking yourself — what is fuel cladding and why does it matter?

To power a nuclear reactor, uranium is processed into small ceramic pellets and stacked into metal tubes called fuel cladding. The ends of the tubes are then sealed to form fuel rods.

Fuel cladding is a barrier between the reactor coolant and nuclear fuel pellets. It is essential to protecting the fuel while also ensuring the safety of a nuclear power plant.

Zirconium alloy has been widely used as a nuclear fuel cladding for decades because of its mechanical properties and corrosion resistance.

While improvements have been made to zirconium alloy cladding over time, there is an interest in exploring and developing new cladding material to significantly improve the operating performance, economic efficiency, and safety of light water reactors.

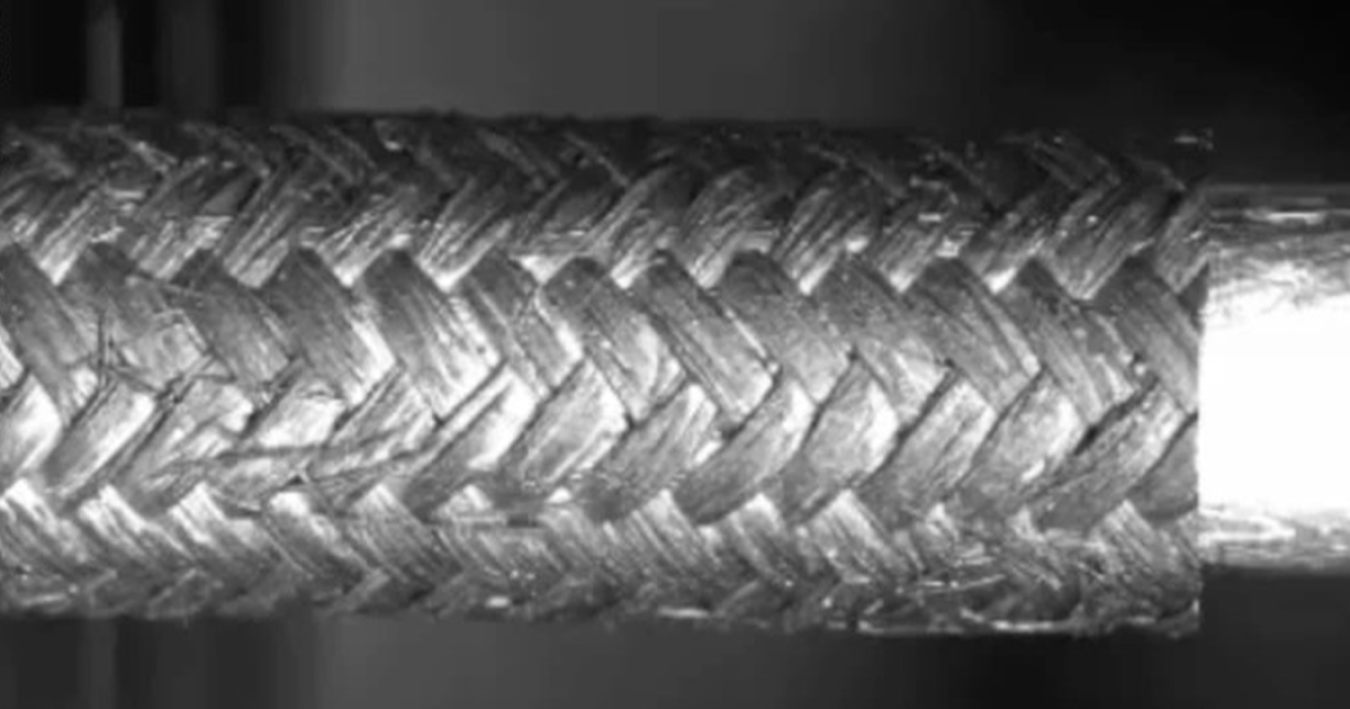

SiGA Cladding Under the Microscope

GA-EMS is developing a new fuel cladding called SiGA® with the help of funding, irradiation testing, and post irradiation examination support from DOE’s Accident Tolerant Fuel Program.

SiGA cladding is made from silicon carbide – a high-temperature ceramic material made of silicon and carbon in a high-purity crystalline composition.

Silicon carbide can survive temperatures hotter than molten lava but can be brittle in its pure form, historically limiting its use as a structural material.

GA-EMS solves this problem by incorporating silicon carbide fiber into its cladding — the fiber reinforces the material similar to the way steel rebar is used to reinforce concrete.

The combination creates an incredibly tough and durable engineered silicon carbide composite material which can withstand temperatures up to 3800°F — roughly 500 degrees hotter than the melting point of zirconium alloy.

Scaling Up SiGA

GA-EMS has already created 6-inch-long SiGA rodlets and 3-foot cladding samples that meet stringent nuclear power reactor-grade requirements and will undergo irradiation testing at DOE’s Idaho National Laboratory.

Recent work has demonstrated the process is scalable to full-length 12-foot fuel rods.

SiGA cladding fully and safely contains the solid fuel and any gasses that are produced during operation and features a novel sealing technology capable of withstanding pressures far beyond that typical of light-water reactor conditions.

To make SiGA cladding a reality, GA-EMS will continue to scale up its manufacturing technology and further analyze SiGA both before and after irradiation. Accelerated fuel qualification methodology is underway using research reactors, commercial reactors, and modeling and simulation.

GA-EMS believes that SiGA cladding is on track to be fully demonstrated by the end of this decade, with commercialization in early 2030. GA-EMS is also developing domestic manufacturing capability of this new fuel cladding.

Also through the Accident Tolerant Fuel Program, three of the largest nuclear suppliers in the United States are working with DOE to develop other accident tolerant fuel concepts for the nation’s fleet of reactors.

These new fuel and cladding mixtures could help improve the overall economics and performance of today’s reactors — and allow for longer response times at high temperatures in accident situations.