National lab develops a system to fabricate solid yttrium hydride to be used as a moderator in compact, high-temperature reactors.

November 10, 2020

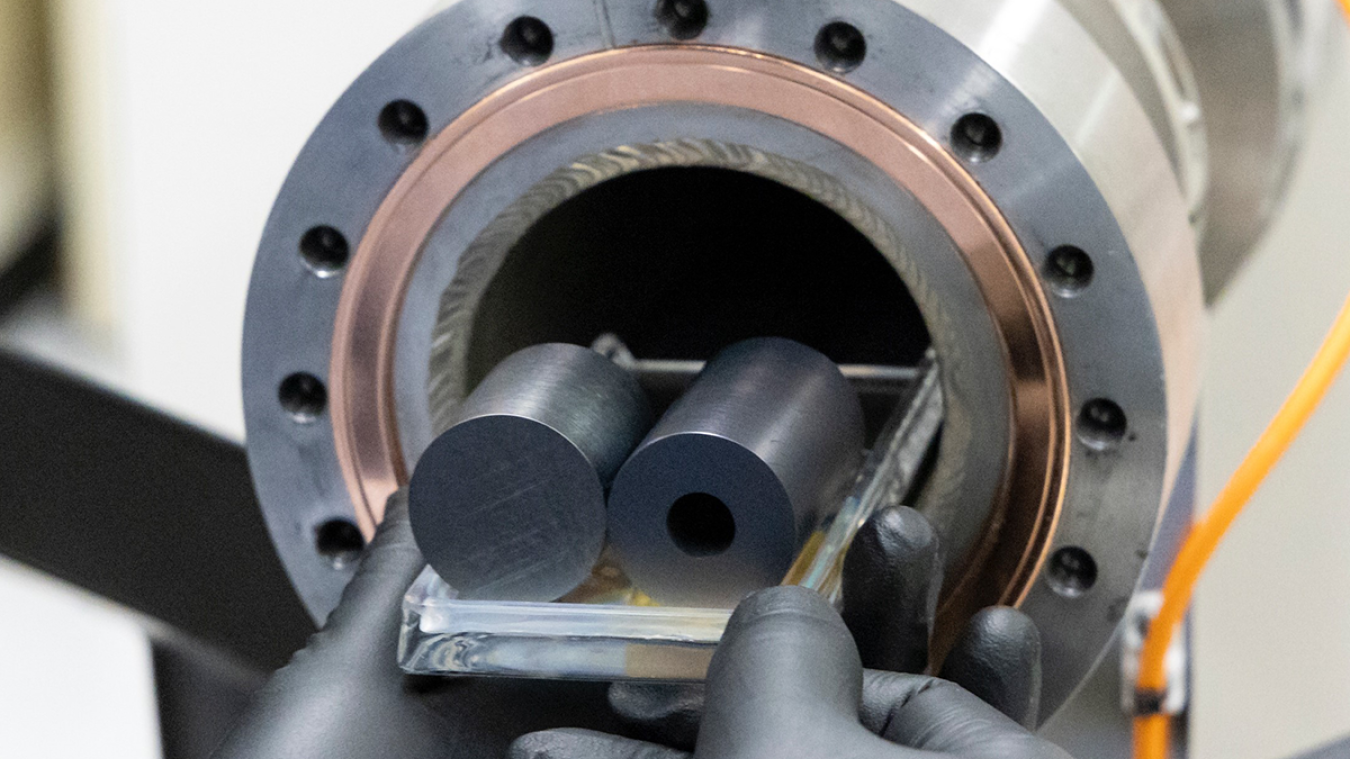

Fabricated samples pulled out of the system

Oak Ridge National Laboratory (ORNL) developed a system to fabricate large quantities of solid yttrium hydride—a rare earth metal and hydrogen mixture that will be used as a moderator for its Transformational Challenge Reactor (TCR). The new moderator is piquing the interest of numerous microreactor programs and could also open up opportunities with NASA as it develops new space reactors and propulsion systems.

Developing the Material

For decades, scientists have been interested in using metal hydrides as a moderator in compact, high-temperature reactors. While most existing reactors use pressurized water as a moderator, metal hydrides contain an equivalent or higher concentration of hydrogen and can work at high temperatures without the high pressure that water requires. The high hydrogen density and moderating efficiency of metal hydrides enables smaller reactor cores that can operate more efficiently and reduce waste products.

Solid Development

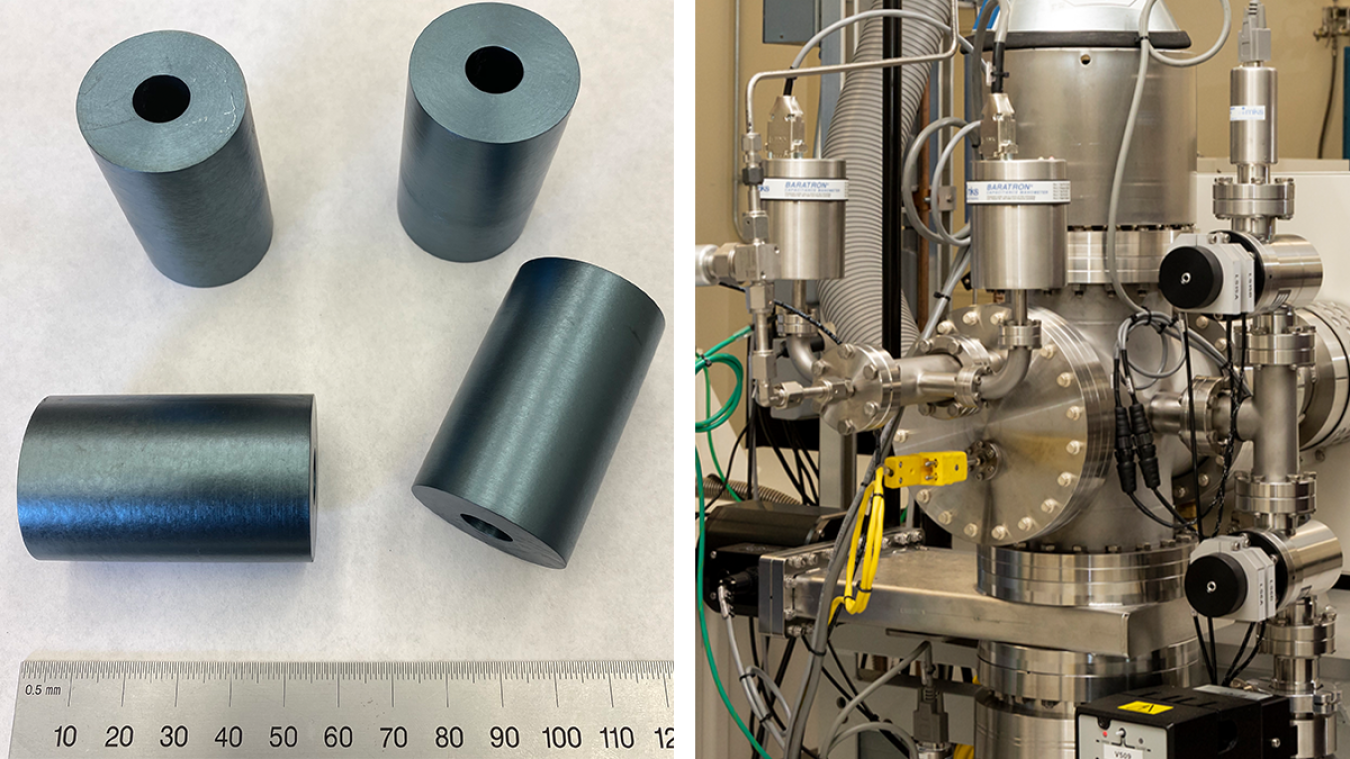

To achieve optimal performance as a high-temperature moderator, the yttrium hydride must be a flawless solid piece. Any cracks in the material can decrease thermal conductivity and impact the release of hydrogen. Yttrium hydride is not commercially available in a solid form, so scientists created a system in just 10 months to mass produce flawless pieces at a scale required for TCR.

ORNL researcher Xunxiang Hu designed a high-temperature, high-vacuum furnace that can process the exact specifications to fabricate large-scale solid metal hydrides.

“It’s easy to just form a hydride powder, but we want a crack-free solid, perfect hydride on a large scale,” Hu said “We experienced a lot of failures, but we learn from our failures … we got it where we wanted it in the first two months.”

Textbook Execution

By the end of the project, researchers had perfected large-scale yttrium hydride production and established a reliable database with detailed information that fully captures its specific characteristics. The process identifies the thermal, mechanical and neutron scattering properties to better determine yttrium hydride’s stability within a nuclear reactor core.

The high vacuum machine’s temperature and gas pressure controls can produce other hydride pieces up to 15 inches long with a 3-inch diameter. This allows for broader application of these low risk, high-density hydrogen storage materials.

Metal hydrides are being considered for use as a moderator in microreactors, advanced small modular reactors, NASA’s nuclear thermal propulsion or nuclear electric systems and other national security related systems. They are also being proposed for use as a shield component for thermalization and neutron absorption in fast-spectrum nuclear reactors. This system will even benefit hydrogen energy.

The TCR design, development and operation of the metal hydriding system is supported by the U.S. Department of Energy. An in-depth summary of this process can be found HERE.