No model is able to capture everything happening at all scales, so it's necessary to really understand the system of interest.

January 29, 2013

Even with the most advanced supercomputing power no model is able to capture everything happening at all scales, so it's necessary to really understand the system of interest by equally understanding the dominant physical parameters of that system. Only these dominant effects will be considered and thus passed from scale to scale.

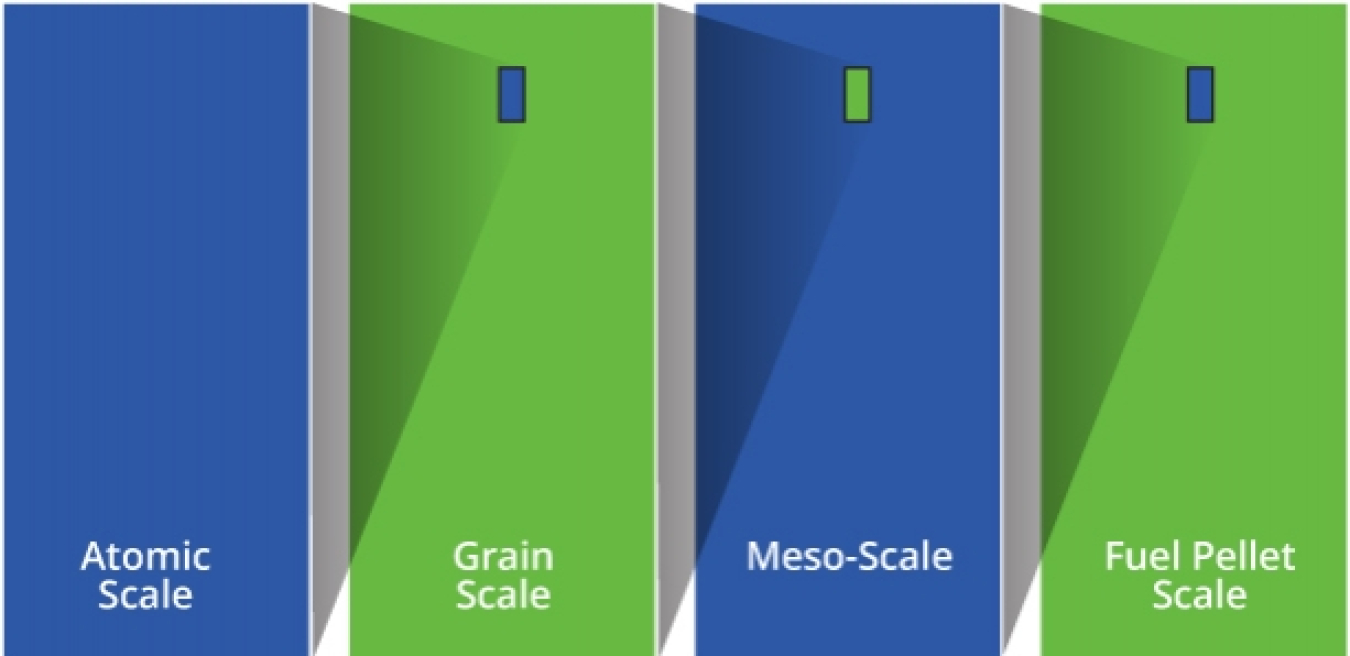

For example, to really understand how fuel rods perform within an assembly one needs to better understand first how the fuel pellets behave within a single rod. A host of other factors need to be considered to accurately model these effects: location within the core, location within the fuel assembly, etc., but generally speaking this logic can be followed all the way down to individual pellets, pellet microstructure, and finally to atoms.

Filling the Micron Gap

Scientists and engineers have fairly robust tools and experimental capabilities to understand fuel performance and behavior from the fuel pin level on up but not so much for nuclear materials at the micrometer length scale down to the atomic scale. Capturing the material properties at these “lower length” scales as well as knowing how to efficiently pass these properties to the next scale (upscaling) is a way to build the predictive capability of the advanced codes. By accurately understanding particular mechanisms or “physics” for processes like material degradation or corrosion, one is better able to understand which parameters are contributing to the largest margins of error (uncertainties) within the simulation outputs and can even recommend additional experiments to capture gaps within the existing body of knowledge to decrease this error.

These fundamental effects need to be considered for both NEAMS product lines. While the local operating physical conditions may vary between the two, a damaged fuel pellet within a rod for the Fuels Product Line versus a damaged fuel assembly within the core for the Reactor Product Line, the underlying mechanisms for the material models are similar enough to be considered for both products. These fundamental material models and upscaling methods are a way that NEAMS is leveraging resources within the program as well as sharing knowledge from and to other similar activities being supported within the Department of Energy.

Key Facts

- A method for building predictability into the NEAMS Toolkit is to correctly capture the material properties at the microstructural level.

- Upscaling, or bridging the scales is an equally complicated challenge for multi-scale simulation efforts.

- While posing a significant challenge, materials and other fundamental modeling efforts are a way to effectively leverage resources.