Maintaining design-level performance over the life of each energy conservation measure (ECM) installed within a utility energy service contract (UESC) is fundamental to achieving projected results.

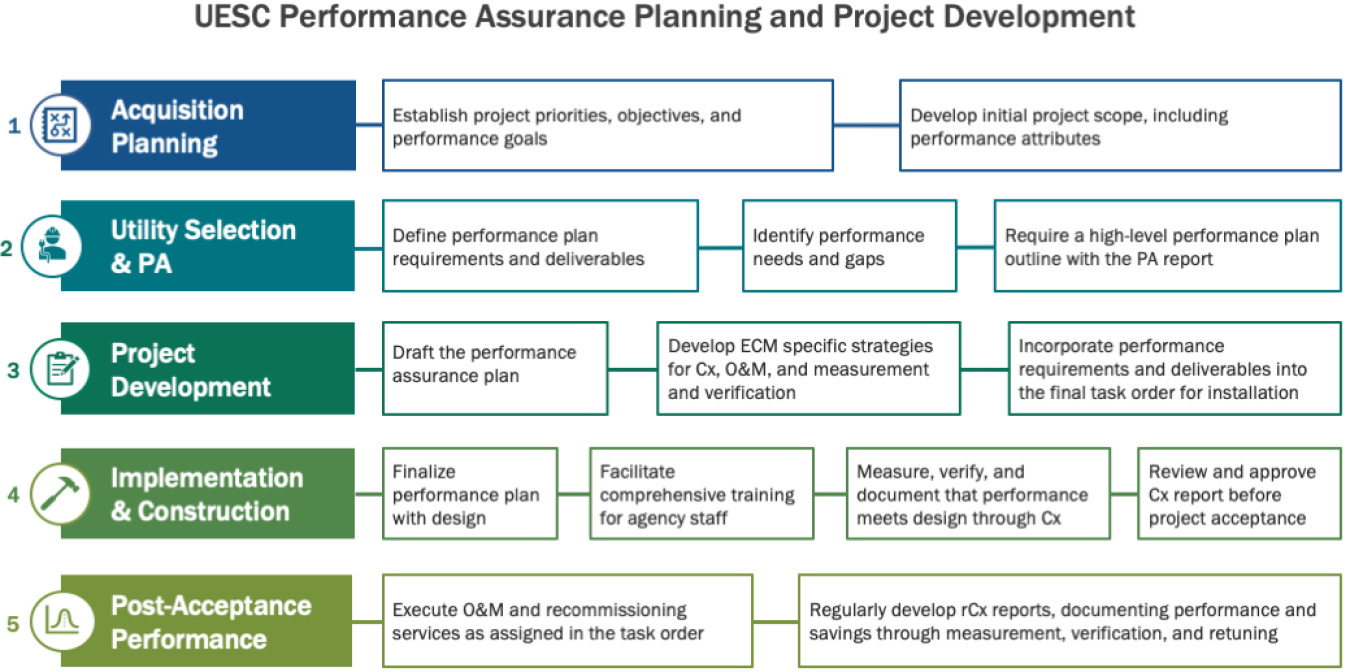

The responsibility for acquiring and sustaining a successful project is ultimately on the shoulders of the agency. Beginning with deliberate performance-focused planning, the most effective tool for achieving success is a well-developed and implemented performance assurance plan. Agencies will establish performance requirements, deliverables, and the obligation to deliver a fully functional, performance proven, and sustainable project through the project task order.

Whether agencies require performance assurance plans with or without energy, water, or cost savings guarantees, agencies may find the Performance Assurance Planning guide informative and helpful in developing ECM-specific protocol, schedules, checklists, and worksheets for verifying performance and savings.

This effort is encouraged and described as a process of performance assurance planning and implementation. A performance assurance plan is, in effect, a commissioning plan, a training plan, and an implementation plan. Preparing the agency to operate, maintain, verify performance, and recommission each implemented ECM is essential whether the post-acceptance implementation will be done by the agency in-house, by the utility team as a requirement of the UESC, or as a performance services contract.

42 U.S.C. § 8253 (f)(5) Follow-up on Implemented Measures

As codified, the installation of any ECM identified through an energy and water evaluations, see 42 U.S.C. § 8253 (f)(3) and (4), in a federal building must include follow-up activities to ensure sustained savings. The development of a performance assurance plan is intended to identify the essential information, activities, schedules, and protocols to support the sustainment of savings for UESCs.

- 42 U.S.C. § 8253 (f)(5) Follow-up on Implemented Measures: The installation of any ECM in a federal building must ensure that:

- (A) Equipment, including building and equipment controls, is fully commissioned at acceptance to be operating at design specifications

- (B) A plan for appropriate operations, maintenance, and repair of the equipment is in place at acceptance and is followed

- (C) Equipment and system performance measured during its entire life to ensure proper operations, maintenance, and repair

- (D) Energy and water savings are measured and verified.

Further, the Office of Management and Budget Memorandum M-12-21: Requires a performance assurance plan, including measurement and verification of savings through commissioning and retrocommissioning in order for the UESC to be scored annually, and the U.S. Department of Defense memorandum, "Policy on Energy Savings Performance Contracts and Utility Energy Service Contracts" (November 20, 2018): Establishes that the utility will be responsible for maintenance, repair, and replacement for UESC projects.

Establish performance goals to ensure the project adheres to federal requirements for follow-up on installed ECMs and achieves expected cost and energy savings.

- Prioritize performance goals early in the project to clarify project requirements and obtain resource commitments.

- Emphasize the importance of maintaining performance throughout the life of the project to justify priority ECMs that may have long paybacks.

- Establish expectations for performance plan and potential services

When performing the initial energy assessment, communicate to the utility that a comprehensive performance assurance plan will be required as part of the final task order. Identify requirements, site capabilities and gaps, and build outcomes into the task order.

Define requirements and deliverables that will make up the performance assurance plan: The agreement should communicate that the preliminary assessment (PA) is to include recommissioning or retrocommissioning and use of eProject Builder task order schedules for UESC. The UESC report template and the performance assurance planning resource may be helpful in developing a performance assurance plan outline.

- The performance assurance plan must address each ECM and include the characteristics of the measure.

- The PA is to include recommissioning or retrocommissioning (RCx).

- The engineering analysis and design is to be based on a complete and accurate baseline with verified assumptions.

- Identify opportunities such as existing software or systems that may support monitoring-based maintenance and commissioning.

The requirements for building the performance assurance plan must be developed by the agency and assigned to the utility via the task order (or areawide contract authorization for energy management services) for the investment-grade audit (IGA).

While the utility is completing the IGA, the agency should begin building the task order for installation. The final task order should define requirements for finalizing the performance assurance plan and implementing assigned tasks.

Develop the performance assurance plan: The performance assurance plan deliverables should be project-specific and include the following elements and subplans.

- Baseline: Provide a complete and accurate baseline.

- Design: Provide engineering analysis, design, operational strategy, and performance metrics.

- Commissioning Plan: A commissioning plan with functional testing and written report (must be implemented and report received prior to acceptance—proving performance meets design specifications).

- Operations Plan: Provide detail needed to operate ECM according to design specifications (provide detail needed to operate according to design for life of the ECM and term of the contract).

- Maintenance Plan: Provide detail needed to maintain ECM at design specifications for life of the ECM and term of the contract.

- Recommissioning Plan: Provide activities, schedules, templates, and instructions to measure, verify, and document performance and savings.

- Comprehensive Training: Prepare agency (e.g., facility energy manager, operations and maintenance staff, and contractor) with training that must address the ECM and each deliverable listed above (i.e., agency must know activities, schedules, metrics, etc.; whether the implementation will be done in-house, as a requirement of the UESC, or as a third-party contract).

Obtain a final proposal complete with performance assurance plan:

- The task order should reflect all the elements listed, as appropriate to each ECM, to support its long-term performance.

- The task order language should establish the requirements, deliverables, timelines, and responsibilities for developing and implementing the plan.

- The task order should describe post-acceptance service assignments, risks, and responsibilities. Include the "what, when, and who" for each ECM.

Best practices: Include RCx to identify low-cost and no-cost improvements, optimize the efficiency of existing equipment and systems, and identify potential ECMs. Consider what responsibilities might be placed upon site staff and resources when planning for sustained ECM performance. Identify organizational gaps that could impede long term performance.

Resources for developing a performance assurance plan:

As ECM designs reach completion, it is critical to finalize the performance plan details by updating operational strategies, performance metrics, and baseline accuracy. The comprehensive training plan should be implemented at this time to ensure agency staff are prepared to operate and maintain the installed ECMs.

Upon installation, the utility will be responsible for measuring and verifying that the performance of each ECM meets design specifications through commissioning, and a commissioning report will be required before the project can be accepted.

Verifying that performance meets design: Verification through commissioning is conducted by the utility and the federal agency to ensure that the proper equipment and systems were installed, are operating correctly, and have the potential to generate the predicted savings.

Agencies must confirm that savings and performance, as stated in the proposal, are met prior to project acceptance. Key performance indicators and commissioning protocol should be defined in the performance assurance plan to ensure expectations are met.

Verification activities specified in the performance assurance plan may include surveys, inspections, spot measurements, and short-term metering. The results are delivered in a performance assurance report developed by the utility before final project acceptance.

Savings guarantees are not a requirement of UESCs but may be added to the contract. When savings guarantees are included in the task order, measurement and verification (M&V) activities will be necessary to confirm that legally and contractually required savings are met. When done correctly, M&V:

- Appropriately allocates risks

- Reduces uncertainty of savings estimates

- Accurately assesses cost and energy savings

- Potentially identifies operations and maintenance issues.

See FEMP's M&V guidelines and International Performance Measurement and Verification Protocol M&V methodologies.

Additional measurement and verification resources:

- Performance Assurance Protocol—Template (see page 17 of the Performance Assurance Planning guide)

- How to Determine and Verify Operating and Maintenance Savings in Energy Savings Performance Contracts (guidance was developed for energy savings performance contracts but is applicable to UESCs with savings guarantees)

- M&V Guidelines: Measurement and Verification for Performance-Based Contracts (Version 4.0)

- Guide to Government Witnessing and Review of Measurement and Verification Activities

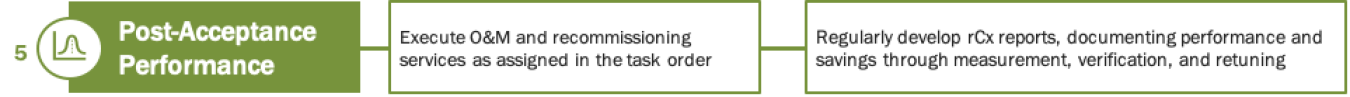

Sustaining and documenting ECM performance is achieved through ongoing operations, maintenance, and recommissioning, including measuring and verifying performance and resulting savings.

Execute operations and maintenance (O&M): Per 42 U.S.C. § 8253(f)(10), post-installation services may be implemented by the utility, agency, or a third-party contractor. Ensure roles and responsibilities are assigned and performed according to the performance assurance plan.

Execute recommissioning: Recommission ECMs including measuring and verifying performance and savings. Document results within the recommissioning report and in eProject Builder.

- Recommission the ECMs at the end of the first year following acceptance and document the findings, including O&M, review and interpret the results, provide recommendations for improving O&M and retuning or repairing as needed, and submit a complete report.

- Recommission each ECM annually, every other year, or at an interval determined to be responsive to the criticality, complexity, or stability of that ECM. Given the flexibility of the UESC method, agencies might consider the most cost-effective interval that supports the complexity of an ECM (e.g., every year for a chiller and every third year for lighting).

- Consider implementing monitoring-based commissioning by establishing an ongoing process of continuous monitoring and analysis of building system data via the continuous monitoring of all building automation system points, control sequences, and schedules. MBCx is the constant application of the commissioning process to a building that has been previously commissioned or retrocommissioned.