Natural Gas Technologies R&D

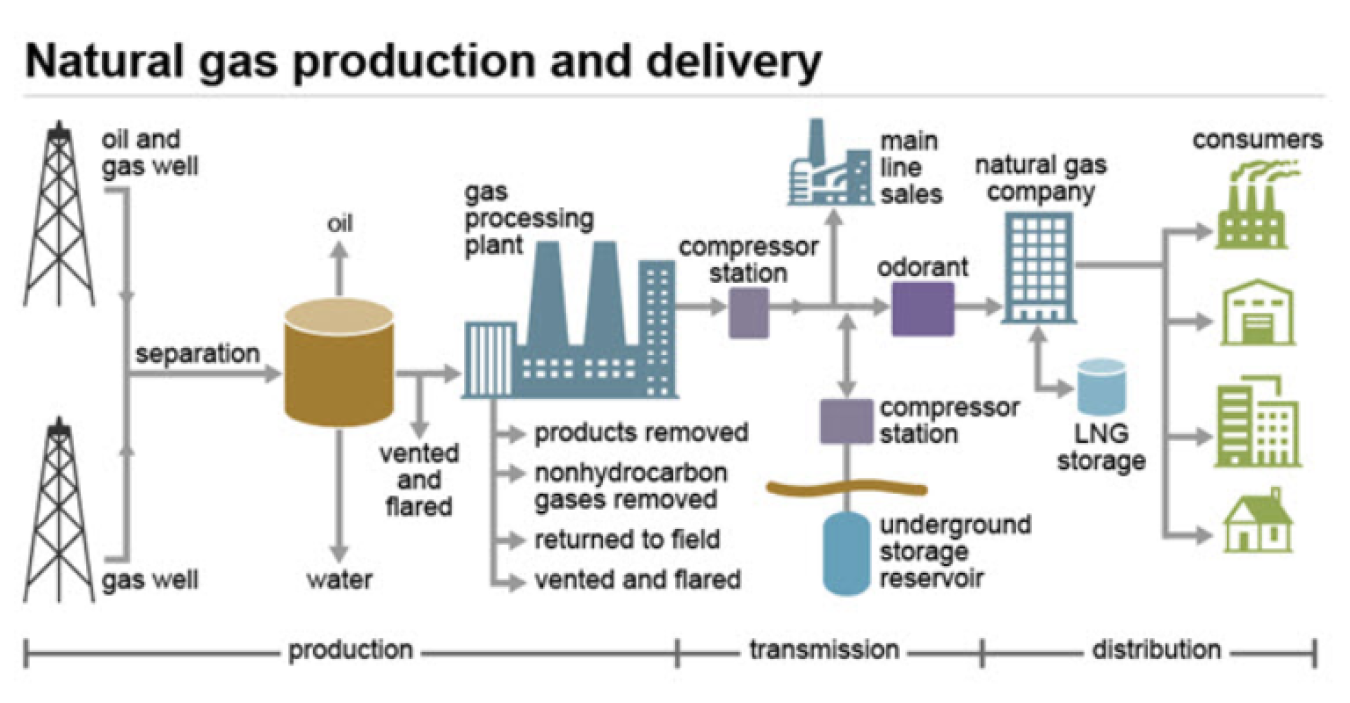

Natural gas is a critical fuel source for the U.S. economy and is delivered to consumers through a natural gas transmission pipeline network that includes more than 210 individual pipeline systems totaling more than 300,000 miles of high-strength steel pipe varying in diameter, normally between 30 and 36 inches in diameter. The primary function of the transmission pipeline company is to move according the Energy Information Administration, over 95 Bcf/day in 2019 of natural gas thousands of miles from producing regions to local natural gas utility delivery points. These delivery points, called “city gate stations,” are usually owned by distribution companies, although some are owned by transmission companies. Compressor stations at required distances boost the pressure that is lost through friction as the gas moves through the steel pipes.

The use of natural gas is increasing, both as fuel and feedstock for industry and as a fuel for electric power generation. A leak or rupture anywhere in a pipeline system can release methane into the atmosphere and cause a significant disruption in transmission service. As the system expands and increases in complexity, natural gas infrastructure must continue to efficiently and cost-effectively support the production and delivery without impacting safety, reliability, and security.

The pipeline transmission system — the “interstate highway” for natural gas — consists of 180,000 miles of high-strength steel pipe varying in diameter, normally between 30 and 36 inches in diameter.

The Natural Gas Infrastructure Program is aligned with the President's objectives to strengthen natural gas pipeline reliability and ensure infrastructure security through research in advanced materials science, real-time sensor technology to measure and mitigate methane emissions and address natural gas infrastructure reliability, public safety, and operational efficiency.

The Natural Gas Technologies R&D program’s goal is to move toward more intelligent pipeline systems that enable continuous monitoring of the system’s status for improved reliability and safety. Advanced data analytics approaches will be integrated into new technology applications, including machine learning and artificial intelligence. Such advanced analytics have the potential to proactively identify early sources of pipeline failure, as well as enabling an understanding of real-time operational parameters that can be used to maximize efficiency and ensure cyber-physical security of the natural gas pipeline infrastructure.

To address the challenge of expanding delivery and transport infrastructure the Program aims to enhance natural gas pipeline reliability and ensure infrastructure security by:

- quantifying infrastructure emissions to contextualize mitigation technology development

- focusing on early-stage research on advanced materials and sensor technology to address the reliability, public safety, operational efficiency, and flexibility of the Nation’s aging natural gas infrastructure.

Advanced materials science research is needed to assess the potential of co-transporting natural gas, hydrogen and CO2 in existing pipeline infrastructure. Material properties dictate the performance limits of an energy technology. Changing these properties in the next generation of material science research, can dramatically improve pipeline reliability and may enable pipes to transport natural gas along with other critical fuel and fluids. When new alloy and composite materials for liners, coatings and sensors are developed and placed in-service by industry, they will improve the operational efficiency of natural gas and other fuel pipeline delivery systems.

By modernizing U.S. energy midstream technologies in a changing global marketplace and supporting fuels diversity through research, demonstration, and analysis, FE’s Division of Supply and Delivery and its partners can develop reliable natural gas technologies that provide energy security benefits, while reducing environmental footprints.

The NGT R&D portfolio consists of research to:

- advance technologies to mitigate methane emissions and increase the efficiency of the natural gas transportation infrastructure;

- support process-intensified technologies for the upcycling of flare gas into transportable, value-added products; and

- further advance methane detection and measurement technology validations.

- enabling more intelligent natural gas infrastructure by demonstrating effectiveness of sensor infused pipeline materials.

- testing alloys and other materials for pipeline liners and coatings that will prevent leakage.

- evaluation of composite pipelines and materials for hydrogen delivery.

Current technologies available for real-time monitoring of natural gas pipelines are focused on the detection of leakages and failures after they have occurred, and are too costly for widespread and ubiquitous deployment. The efforts underway target to develop a suite of sensing and monitoring tools which are cost-effective and enable the identification of incipient leaks and failures before they occur. Sensing technologies under development include optical fiber, passive wireless, electrochemical, and spectroscopic technology platforms. Targeted parameters of interest focus largely on chemical species which are indicative of the on-set of corrosive conditions, corrosion on-set and rate of corrosion, and low-level methane detection.

Advanced materials and liners under development are being tailored to protect the natural gas pipeline infrastructure from the primary sources of internal corrosion that can threaten the infrastructure integrity. Metallic coatings are being developed and deposited to serve as sacrificial protection layers, and engineered polymeric coatings as well as hybrid inorganic / organic liners are being developed to prevent corrosive species from reaching the surfaces of natural gas pipelines.

Through incorporation of advanced sensing technologies with pipeline materials and/or protection coatings and liners, natural gas pipelines with embedded intelligence can be realized to provide enhanced reliability, public safety, operational efficiency, and flexibility of the aging natural gas infrastructure.

Advancing these research objectives are important to achieving the goal of optimizing the performance of a critical part of the U.S. energy delivery system that is growing rapidly and that will become increasingly important into the future. Increasing development, transport and use of domestic natural gas resources is forecasted to continue for the foreseeable future.