The Carbon Conversion program’s mineralization pathway focuses on the development of CO2 conversion technologies in which CO2 mineralizes with alkaline reactants to produce inorganic materials such as synthetic aggregates, bicarbonates, and associated building materials. Carbonate materials present an effective long-term storage option for CO2, especially for use in the building industry. Additionally, construction materials represent a large potential market for CO2-based products if costs and other barriers to entry can be overcome. The research priority in the mineralization pathway includes further studies into relative rates of carbonation and hydration to control carbonation and curing reactions. Additional priorities are to integrate CO2 capture with mineral carbonation technologies and investigate additional alkaline sources for mineralization, such as mining wastes and produced waters.

The mineralization pathway is implemented by the National Energy Technology Laboratory, which oversees both internal and external projects. The current project portfolio includes approaches that generate a wide variety of products, including precipitated calcium carbonate, precast concrete products, multi-functional concrete, and construction materials.

One of the most significant challenges of converting CO2 is thermodynamics mainly because it is a very low-energy molecule. For most applications, a form of energy (either thermal, chemical, or electrical) has to be added to convert CO2 into a different molecule to form products such as fuels and chemicals. In contrast, carbonates are even lower in energy than CO2, which minimizes the energy needed to form them. When CO2 is incorporated into the production of cement and aggregate, forming carbonates, it is not necessary to add energy to overcome thermodynamic constraints. This is important because the energy required to make large volumes of material could be extremely expensive, rendering the materials non-cost competitive. (1)

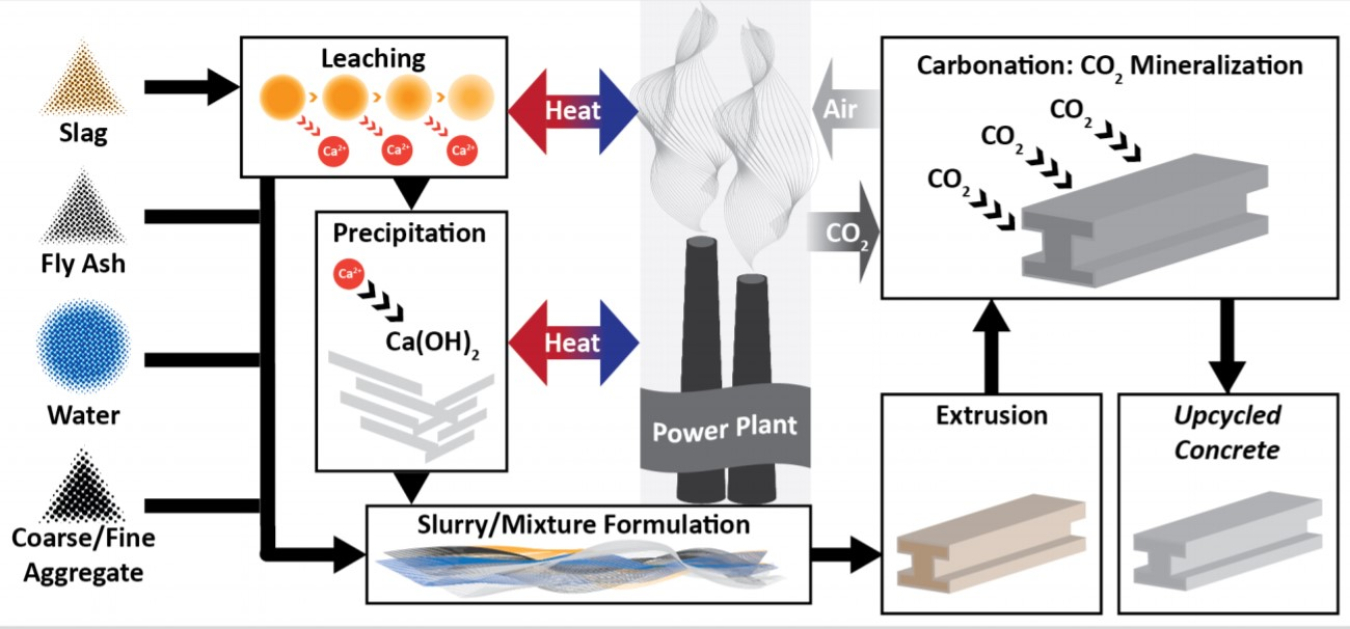

The graphic below illustrates how CO2 can be incorporated into concrete materials.

[1] Carbon Dioxide Utilization (CO2U) ICEF Roadmap 2.0. View road map

[2] Sant, G. 2019. Upcycled “CO2 -negative” concrete for construction functions. US DOE/NETL Annual Meeting, Carbon Capture and Utilization, August 2019, Pittsburgh, PA. View presentation