The APS system has the potential to revolutionize the fabrication of specialty metals. Adoption of this technology can improve the quality of the ingots produced and reduce the amount ingot testing required, saving manufacturers millions of dollars. In...

Office of Fossil Energy and Carbon Management

April 18, 2017

Contrary to that old cooking adage, “a watched pot never boils,” keeping a careful eye on things, – in the kitchen or in the laboratory, – can be essential to making a useable or edible final product.

Take chocolate, for instance. An important part of creating high-grade chocolate is a step called tempering, or the melting, stirring, and cooling of the liquid chocolate to align the crystals that give it a smooth texture and a glossy shine. One of the key senses chocolatiers use to monitor tempering is sight, giving them information on the thickness and color of the batch to make sure it tempers evenly as it cools.

But what if they had to do it blind?

For many years, that’s exactly what metallurgy laboratories across the world have been doing. While crafting specialty metal alloys like titanium or zirconium, can be far more complex than making chocolate, metals are often put through a process similar to chocolate tempering called vacuum arc re-melting (VAR). VAR is an important step in metal fabrication which makes the material chemically and physically homogeneous to ensure a quality end-product.

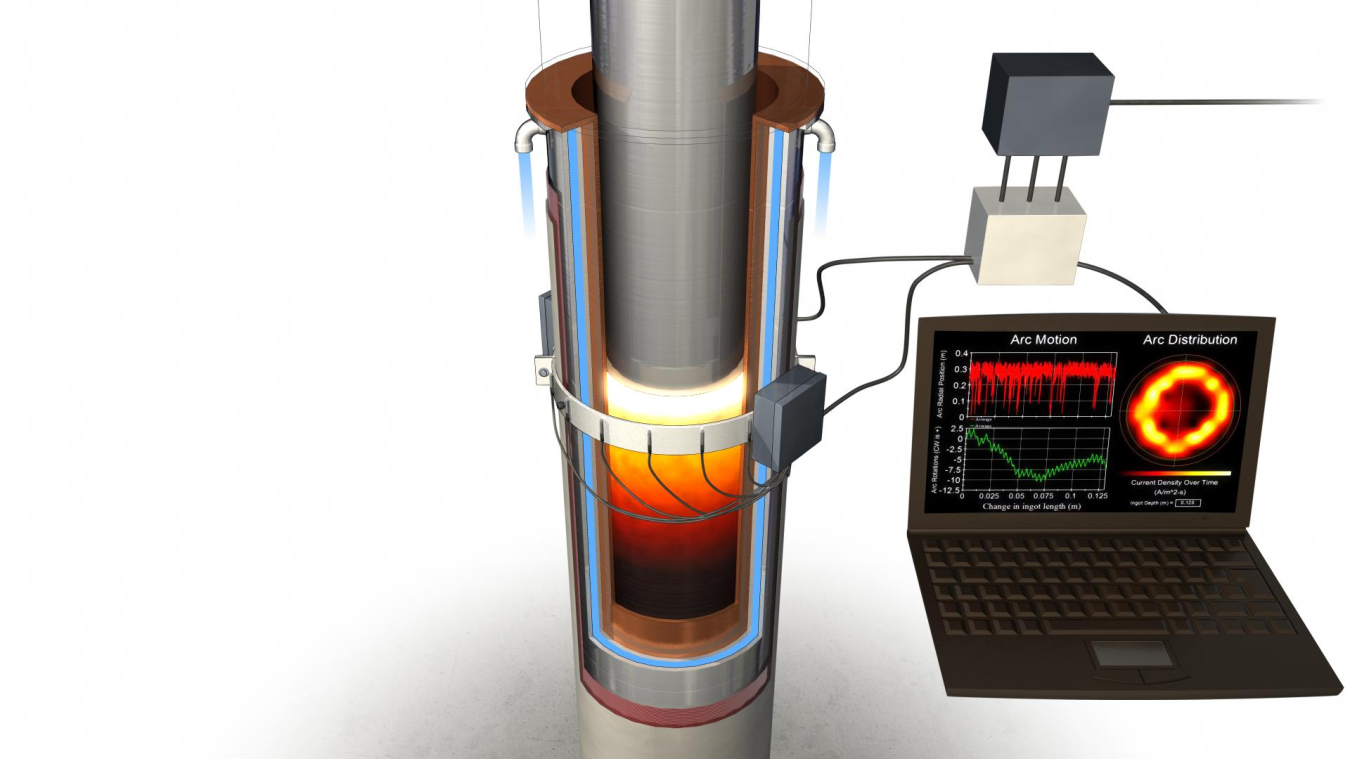

During VAR, an electric arc – a luminous electrical discharge like a lightning strike – is used to heat a consumable electrode. Then, the melting material drops into a water-cooled copper crucible. Like chocolate, flaws in specialty metals are often caused by solidification problems that arise during this melting and refining process. But unlike chocolate, these products are used in aerospace and aviation applications, where lives depend on quality metal components within these vehicles.

Previously, the conditions that cause flaws in alloys could not be identified during furnace operations, requiring manufacturers to perform extensive testing on the resulting ingots to test for safe levels of homogeneity. However, a new process developed by metallurgists at the Office of Fossil Energy’s National Energy Technology Laboratory (NETL), called arc position sensing (APS), allows operators to digitally monitor arc location during VAR processing. Being able to “see” the arcs during melting helps engineers control them. Thanks to the development of this technology, the melting process can produce consistently defect-free materials—something that was not possible prior to the development of this technology.

The APS system has the potential to revolutionize the fabrication of specialty metals. Adoption of this technology can improve the quality of the ingots produced and reduce the amount ingot testing required, saving manufacturers millions of dollars. In addition, APS could also lead to production of materials with better chemical homogeneity, resulting in higher performance alloys.

This patented and award-winning technology has been licensed by AmpSci, an Oregon-based company founded by the technology’s inventors. Researchers at AmpSci are working to further develop the technology for widespread commercial deployment to the specialty metals industry. You can learn more about this NETL success story here.