Offshore Liquefaction. Floating Liquefied Natural Gas (FLNG) systems are a relatively new technology for the LNG industry.

Hydrocarbons and Geothermal Energy Office

February 24, 2021Technologies for Offshore Liquefaction and Regasification: FLNGs and FSRUs

Offshore Liquefaction. Floating Liquefied Natural Gas (FLNG) systems are a relatively new technology for the LNG industry. They are used for liquefying natural gas produced from offshore fields that may be located too far offshore to make onshore liquefaction feasible. FLNG systems are water-based vessels that are deployed over an undersea natural gas field. In general, FLNG systems produce, treat, liquefy, store and transfer LNG via carrier ship to global markets or to onshore infrastructure that transmits the gas to domestic markets.

The first such facility completed that produced LNG was Petronas’ PFLNG Sate, offshore Malaysia, in 2017. Shell’s Prelude, brought online in 2019, is the largest FLNG facility, and the largest offshore facility ever built. There are still only a handful of FLNG facilities in operation due to high costs and technical challenges. However, FLNG systems continue to attract interest and investment by countries and companies looking to take advantage of their offshore gas resources.

Figure 4. Petronas' PFLNG Sate facility, offshore Malaysia

Courtesy of Offshore Technology

Some of the benefits of FLNG systems include:

- the ability to reach and develop more remote gas fields that would be too technically or economically challenging to develop otherwise;

- the elimination of long pipelines and onshore facilities, reducing capital costs and potentially increasing environment benefits; and

- the ability to be redeployed to newly discovered offshore fields, reducing the time needed to bring a field online and the need for further construction.

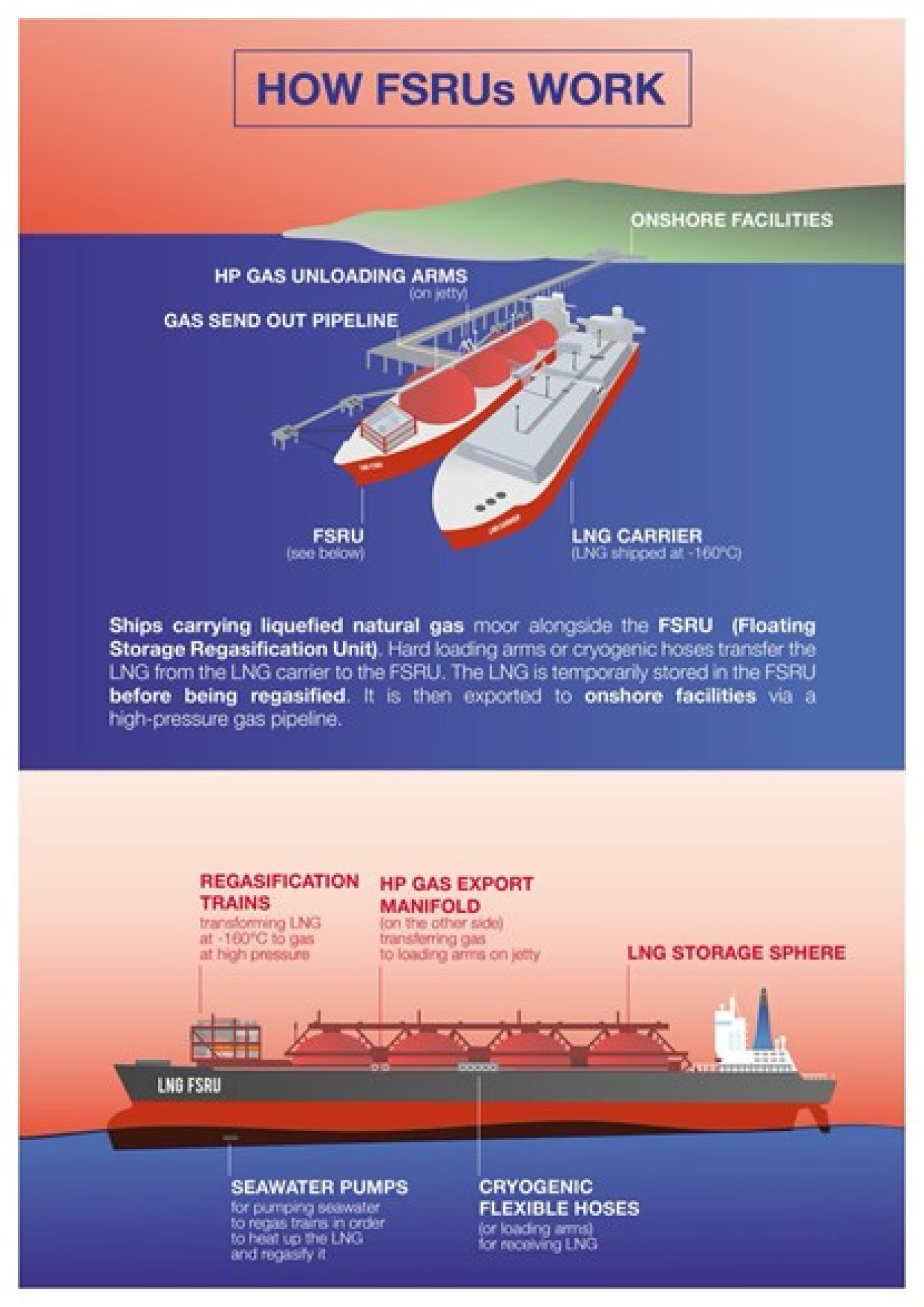

Figure 3. FSRU schematic courtesy of Total

Offshore Regasification. The use of floating storage and regasification units (FSRUs) in the global LNG market has grown significantly in the past two decades, especially in developing countries. FSRUs are specialized ships, or offshore vessels, that receive, store, and vaporize LNG back into gaseous natural gas to provide fuel for power generation, feedstock for industrial practices, heat for residential and commercial facilities, and other end-uses.

Some FSRUs are converted LNG carriers, and some are purpose-built. These vessels are moored in harbors or offshore in open water. FSRUs receive LNG to store and regasify LNG from a LNG carrier via a ship to ship transfer, where, after vaporization, the gas is metered and transmitted to an onshore gas pipeline network or large end-users.

FSRUs are more economic to construct than onshore regasification facilities, consisting up to 50% less than a comparable onshore facility. They can be leased, making them quicker to put into operation, and can be used flexibly for shorter periods than permanent infrastructure.