Workers at the Hanford Site Waste Treatment and Immobilization Plant (WTP) have begun removing the first three of 18 temporary startup heaters.

Office of Environmental Management

September 12, 2023

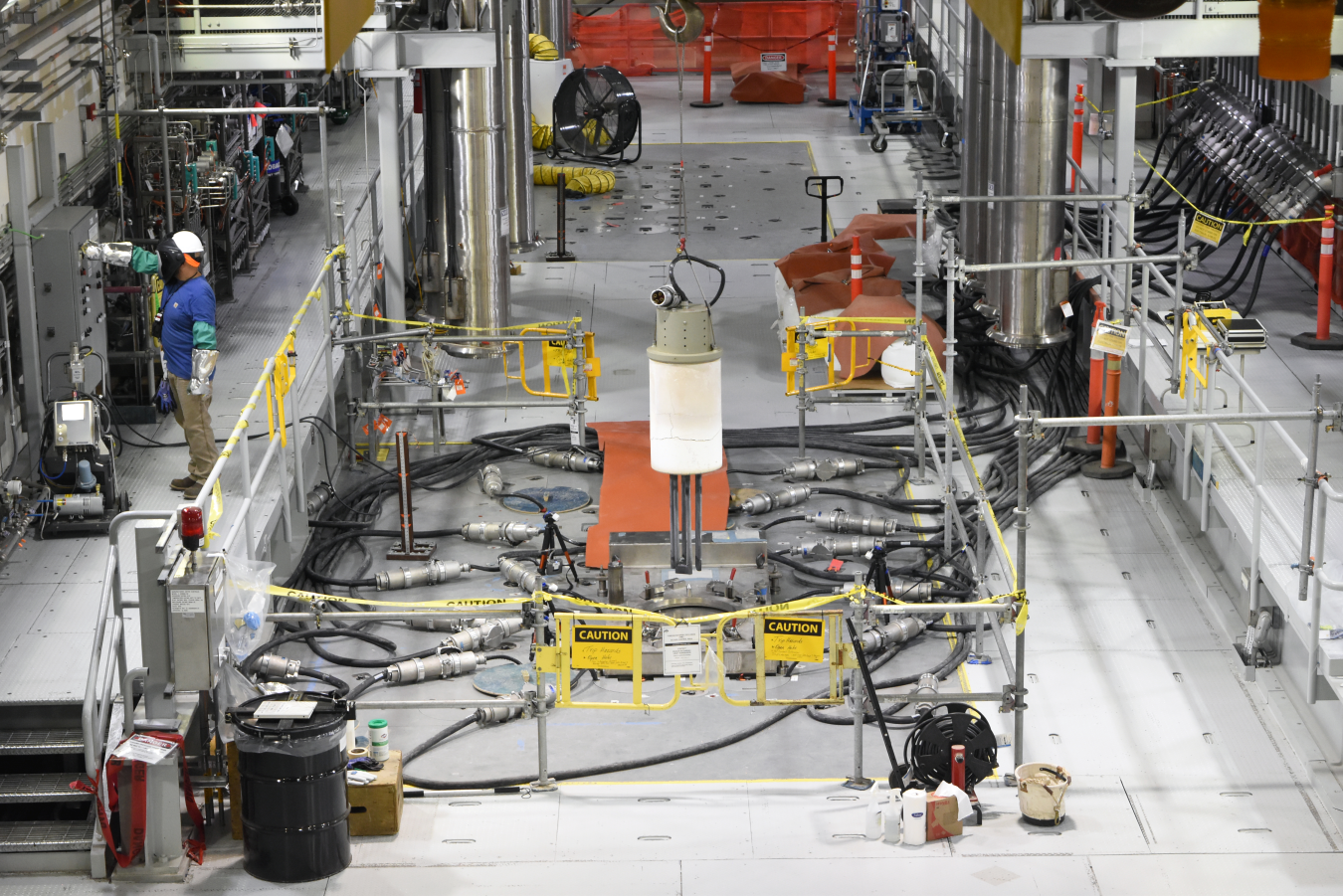

RICHLAND, Wash. – Workers at the Hanford Site Waste Treatment and Immobilization Plant (WTP) have begun removing the first three of 18 temporary startup heaters. The startup heaters were used to raise the first of two 300-ton glass melters in the Low-Activity Waste Facility to its operating temperature of 2,100-degrees Fahrenheit. Crews began removing the heaters after establishing a pool of molten glass in the melter using glass beads, or frit, and initiating Joule heating, which passes electrical current through the molten glass to produce heat. The crews replaced the startup heaters with bubblers, which circulate the molten glass using air to maintain a consistent mixture and temperature. The remaining startup heaters will be removed and replaced with bubblers after the final molten glass level is reached. During direct-feed low-activity waste operations, Hanford tank waste will be heated inside the WTP’s melters and mixed with glass-forming materials. The mixture will then be poured into stainless steel containers and allowed to cool before being disposed of in a specially engineered landfill on the Hanford Site called the Integrated Disposal Facility.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.