Workers at the Hanford Site’s Waste Treatment and Immobilization Plant are sporting a new accessory for the first time: radiological dosimeters

Office of Environmental Management

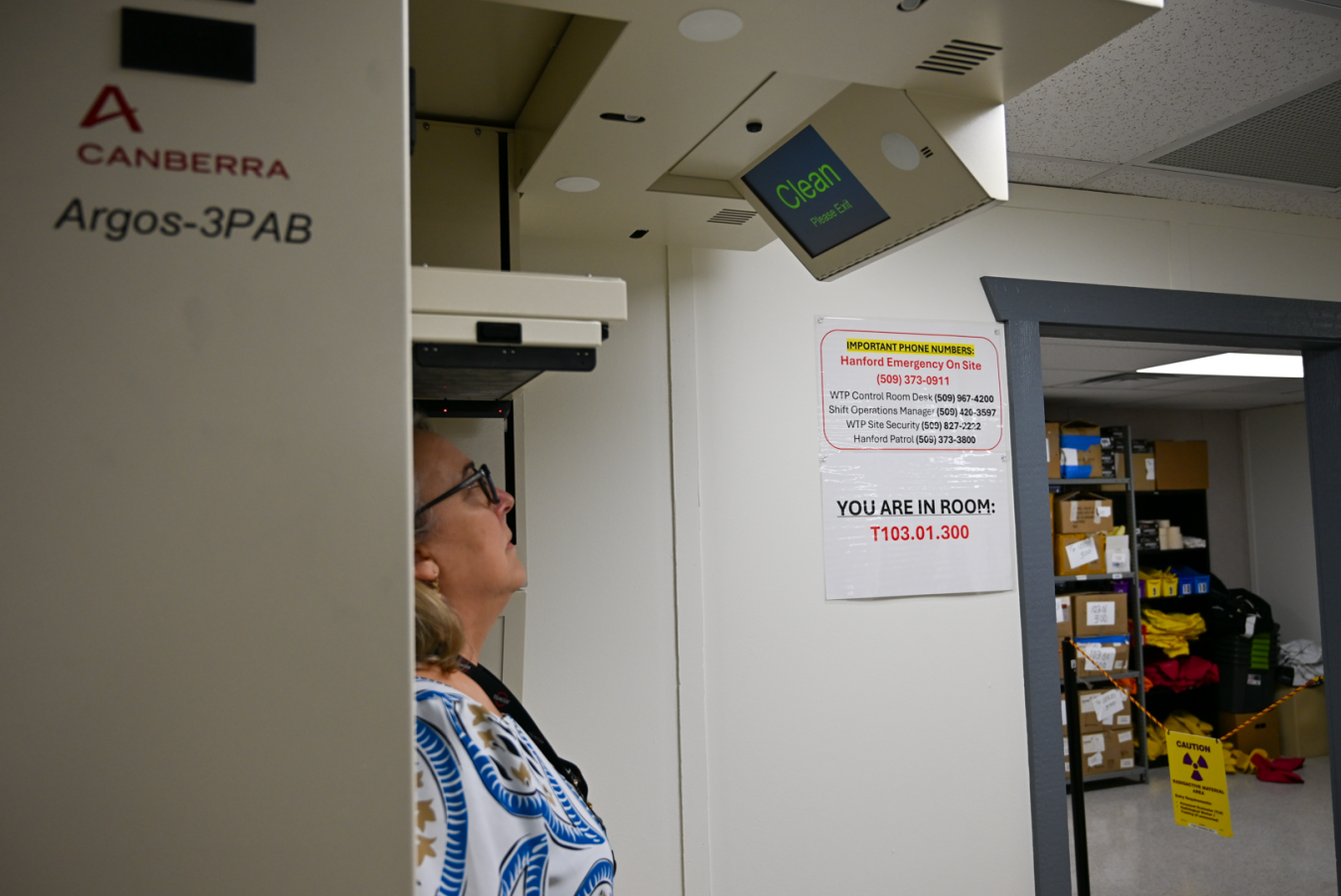

February 18, 2025Bechtel National Inc. Manager Joni Weamer practices using a whole-body monitor to check for radiation during training at the Hanford Site’s Waste Treatment and Immobilization Plant.

RICHLAND, Wash. — Workers at the Hanford Site’s Waste Treatment and Immobilization Plant are sporting a new accessory for the first time: radiological dosimeters. These small devices worn on workers’ clothing measure radiation exposure. Their use is another visible sign of how close the project is to processing tank waste into an immobilized form safe for disposal.

“We are preparing to introduce radiological and chemical waste into the plant,” said Mat Irwin, Hanford’s assistant manager for the Waste Treatment and Immobilization Plant Project. “These early preparations help the team become proficient in radiological operations and requirements while reinforcing a nuclear operations safety culture prior to receiving the actual waste.”

During plant operations, specially designed underground pipes will transfer radiological and chemical waste from Hanford’s large underground tanks to the plant’s Low-Activity Waste Facility. There, in a process called vitrification, the waste will be mixed with glass-forming materials and heated to 2,100 degrees Fahrenheit inside one of two large melters, then poured into stainless steel containers for safe disposal.

Bechtel National Inc. Manager Joni Weamer practices putting on and taking off protective clothing during radiological worker training at the Hanford Site’s Waste Treatment and Immobilization Plant.

Workers have also added new contamination and radiation signage at the Low-Activity Waste Facility. The new postings help employees grow accustomed to the hazard warnings and restrictions before plant operations begin.

The plant’s Radiological Controls team has created new programs to help workers develop proficiency in radiation safety, and weekly computer-based and hands-on learning simulations.

“The shift to radiological operations will be a significant change in our operations and safety culture, and we are preparing the people, plant and paper for this milestone,” said Chris Musick, general manager for Waste Treatment Completion Company, the main subcontractor for Bechtel National Inc., the prime contractor designing, building and commissioning the plant. “The proficiency phase symbolizes the real progress made by our team in moving closer to full plant operations later this year.”

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.