The Separations Process Research Unit (SPRU) Disposition Project completed a significant waste-treatment campaign today that involved the solidification of approximately 9,700 gallons of contaminated sludge, and 14 shipments of the waste off-site for perm

EM Consolidated Business Center- New York (EMCBC-NY)

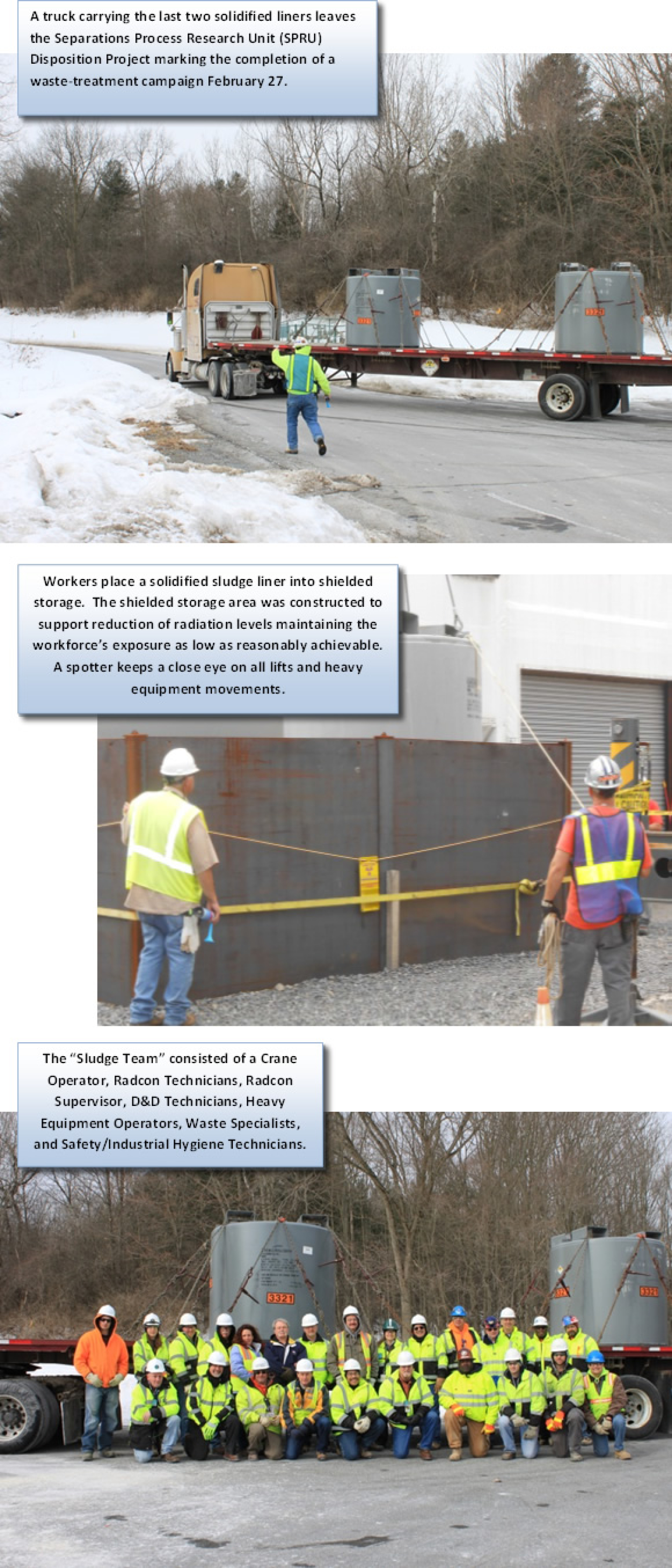

February 27, 2014Niskayuna NY (February 27, 2014) - The Separations Process Research Unit (SPRU) Disposition Project completed a significant waste-treatment campaign today that involved the solidification of approximately 9,700 gallons of contaminated sludge, and 14 shipments of the waste off-site for permanent disposal. The shipment of this material removed the majority of the radioactivity at the SPRU facilities. The Department of Energy’s Office of Environmental Management (EM) is responsible for the decontamination, demolition, and cleanup of the 65-year-old Cold War facility, with work being performed under contract with DOE by the URS Corporation. SPRU is collocated with DOE’s Knolls Atomic Power Laboratory in Niskayuna, NY.

"The radioactive sludge constituted one of the highest risks at SPRU," said Steven Feinberg, the EM manager of the project. "The successful solidification of the sludge marks major progress in our environmental cleanup project, and enables us to put our full attention on moving ahead with the active decontamination and demolition of unused buildings at the site."

The sludge resulted from historic research into the chemical separation of plutonium, which was shut down in the early 1950s. The solidified sludge, in 28 shielded liners, is being disposed at a licensed, commercial low-level radioactive waste disposal facility in Andrews, TX, which is owned and operated by Waste Control Specialists, LLC.

In addition to successfully completing the sludge solidification project, the SPRU Disposition Project achieved more than 2 ¾ years and more than 1.1 million safe work hours without a lost-time accident or injury. "This record was accomplished while overcoming numerous obstacles associated with the high-hazard construction, decontamination and demolition work at the site," noted Bobby Smith, Project Manager for URS at SPRU. "That included working at heights to construct the Sludge Processing Tent, install ventilation and sludge system components, decommission the old sludge processing system, and safely operate the waste solidification system."