NREL completed the assembly and began testing a new drivetrain design that can increase reliability, improve efficiency, and reduce the cost of wind energy tremendously. Upon the successful completion of testing, technology readiness levels will be adv...

Wind Energy Technologies Office

May 18, 2015

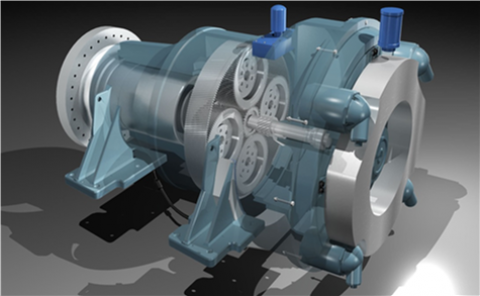

In February, engineers at the U.S. Department of Energy’s (DOE’s) National Renewable Energy Laboratory (NREL) assembled the innovative, medium-speed, medium-voltage wind turbine drivetrain that was the result of a study funded by DOE’s Wind Program. The goal of the first phase of the project, which began in 2011, was to design an advanced wind turbine drivetrain that could be scaled to larger turbines and that would significantly reduce the cost of wind energy. The design produced by the NREL team, which included CREE, DNV KEMA, and Romax Technology, can increase reliability, improve efficiency, and reduce the cost of wind energy tremendously. In addition, the design can scale up to ratings as high as 10 megawatts (MW).

In 2013, the team was awarded follow-on funding to develop a prototype and demonstrate the technologies’ commercialization potential. The prototype incorporates a systems approach that focuses on all three of its major components: a single-stage gearbox, a medium-speed permanent-magnet generator, and a high-efficiency power converter. The new gearbox consists of a single planetary stage that uses compliant flex-pins and journal bearings to support the planets, eliminating the lower-reliability, higher-speed stages found in traditional gearbox designs. Traditional three-stage high-speed gearbox designs have been plagued with reliability issues caused by the large and unpredictable loads imparted on the gears and bearings by the wind acting on the rotor, and by utility faults acting through the generator. This new configuration improves the load distribution and increases the drivetrain’s overall reliability.

The team’s new power converter incorporates innovative software algorithms that are grid-friendly, compliant with emerging requirements, and support the continued growth of wind power as a large contributor to power generation. The team also will be exploring medium-voltage, wide-band-gap, silicon-carbide power modules. These state-of-the-art power modules are expected to significantly reduce the losses within the power converter, leading to increased efficiency, energy capture, and revenue.

The team began testing the drivetrain prototype in the 2.5-MW dynamometer and the controllable grid interface at the National Wind Technology Center at NREL in April. Upon the successful completion of testing, technology readiness levels will be advanced and combined with a commercialization plan that will lead to global deployment of the drivetrain technologies. Successful deployment of the more efficient, reliable drivetrain will further reduce the cost of wind energy and ensure that U.S. companies are at the forefront of technical innovation within the global wind energy industry.