Three national laboratories are demonstrating the technical and economic benefit of integrating run-of-river plants with energy storage.

Water Power Technologies Office

January 13, 2021Throughout 2019‒2020, Idaho National Laboratory (INL) worked closely with Argonne and NREL to demonstrate the technical potential and economic benefit of co-locating and coordinating multiple run-of-river hydropower plants with different types of energy storage devices, creating “virtual reservoirs” with potential to function similarly to conventional reservoir-based hydropower plants. Partnering with Siemens, the project team developed a centralized control scheme, the Smart Energy Box, to coordinate operation of different energy storage devices at one or multiple hydropower plants. The project also succeeded in applying market participation modeling to assess the ability of hybrid energy storage systems to perform similarly to conventional hydropower plants in responding to grid needs, opening the door for potential new markets for run-of-river owner/operators to participate in.

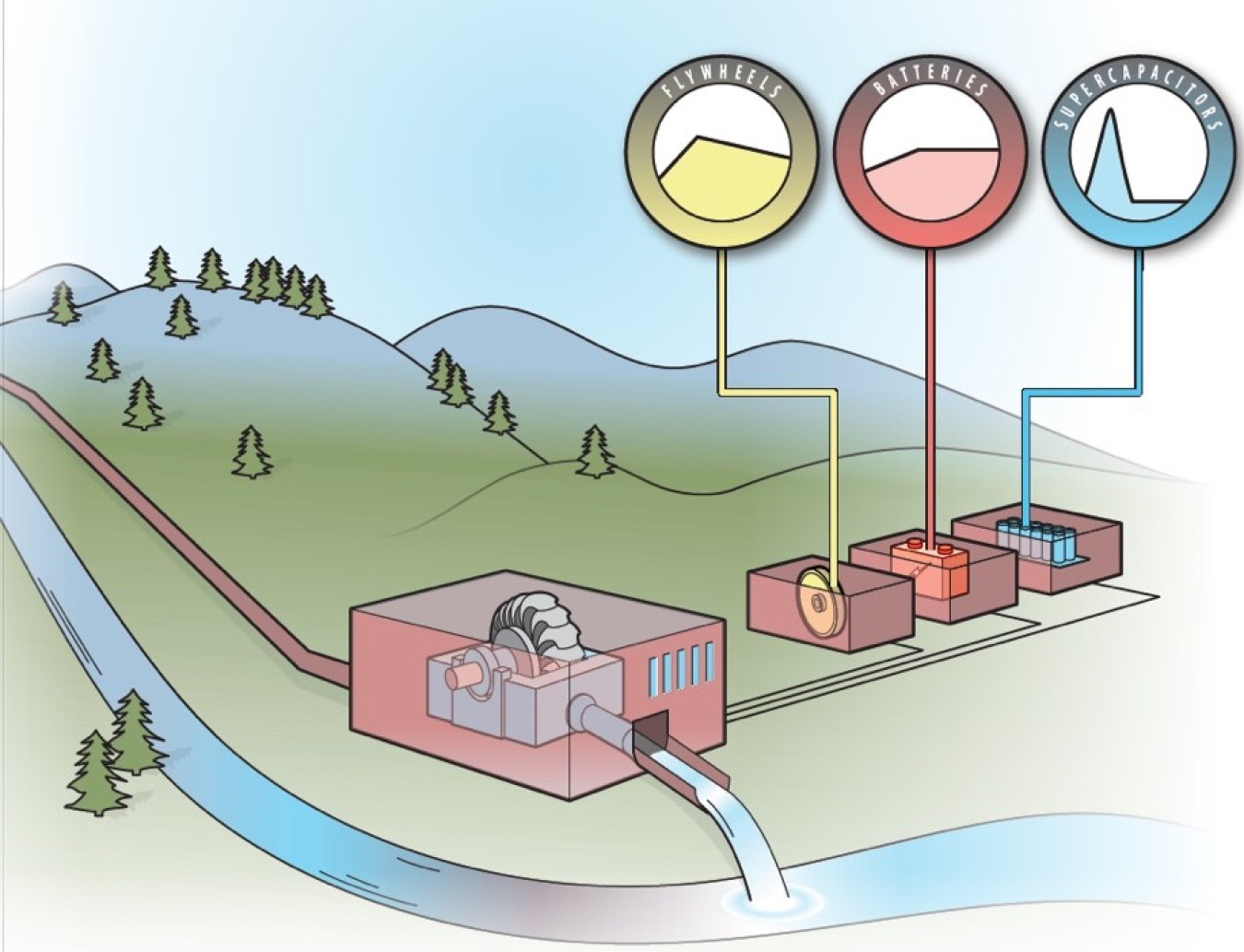

Initiated in 2016 with support from WPTO, the first phase of the project (2016–2019) looked at demonstrating the technical feasibility and financial performance of combining energy storage systems with run-of-river hydropower plants to provide a greater range of grid services. Nearly half of the U.S. hydropower fleet operates as run-of-river. Whereas reservoir-based plants have usable storage that allows them to shift or withhold water releases for generation during higher value times of the day, run-of-river facilities have little to no ability to control the timing of water releases. The team demonstrated that integration of energy storage (e.g., batteries, flywheels, and/or ultracapacitors) can enable a run-of-river hydropower plant to perform similarly to a hydropower plant with reservoir storage.

A key accomplishment from the team is the development of Siemen's innovative Smart Energy Box, which coordinates operation of multiple units/plants and energy storage devices and can be optimized for providing services and performance desired by the owner/operator. The Smart Energy Box monitors grid operator signals and determines how to meet programmed objectives using all connected devices most effectively. It can be used to enable a broad range of benefits, including provision of ancillary services, or reduction of ramping speed and the frequency of hydropower generators, which can have positive outcomes on wear-and-tear rates.

Another accomplishment was the application of Argonne’s Conventional Hydropower Energy and Environmental Systems (CHEERS) model to simulate and optimize market participation of integrated hydropower and energy storage systems. CHEERS optimizes day-ahead scheduling and real-time operations for hydropower by considering multiple objectives (e.g., cost, power, environmental considerations) to support decision-making on unit commitment and turbine-level operating points. For this project, the team expanded the capabilities of CHEERS to include energy storage configurations and ensure all the complexities of modeling a storage device (e.g., state of charge, storage life) were accurately represented. This capability allowed CHEERS to not only readily analyze the value of different integrated hydropower and energy storage systems, but also develop an understanding of how the value of such a system could be maximized.

To demonstrate these concepts in a real-world scenario, researchers completed a case study in partnership with Idaho Falls Power, the local municipal utility, which owns and operates four cascaded run-of-river hydropower plants. Using the utility’s operational data, the team performed real-time simulations of energy storage hardware with the run-of-river hydropower plants to assess the performance enhancements from hybrid energy storage systems, demonstrating that a run-of-river hydropower plant integrated with energy storage can respond to a frequency event like a conventional hydropower plant. Using Argonne’s CHEERS model and real-world market, water, and plant capability data, the team found integrating energy storage with Idaho Falls Power’s hydropower facilities can boost revenue by 12% to 16%.

Phase II of the project began in 2019 and focuses on applying the tools, models, and capabilities developed in Phase I to a series of use cases. The first use case is being explored in partnership with Idaho Falls Power and uses ultracapacitors integrated with a run-of-river hydropower plant to enable black-start capability. Black-start capabilities at the distribution level would enhance system reliability and allow hydropower owners/operators to restore services in islanded mode, reducing downtime for customers if an event occurs and improving grid resilience. This capability will be demonstrated in a field test with Idaho Falls Power during 2021.

Follow-on work will include increasing the set of services that can be provided using the technology, demonstrating the technology through field deployments in partnership with industry, and developing guidance on topics such as sizing optimization to accelerate implementation. Additionally, in 2021 INL plans to develop a prototype energy storage selection tool to help hydropower owners/operators that are considering hybridizing their plants to select appropriate technologies and optimal sizes based on their storage needs.

For additional information, contact Thomas Mosier.