-- This project is inactive --

Sandia National Laboratories (SNL), under the National Laboratory R&D competitive funding opportunity, developed, characterized, and refined advanced solar-selective coatings with high solar-weighted absorptivity (a > 0.95) and low emittance (e < 0.40) for concentrating solar power (CSP) power tower receivers that can operate in air at temperatures = 650°C without degradation for =10,000 cycles. These performance qualities are required for the next-generation receivers that must reach the SunShot Initiative's annual average thermal efficiency target of 90% and cost target of $150/kWth or less.

Approach

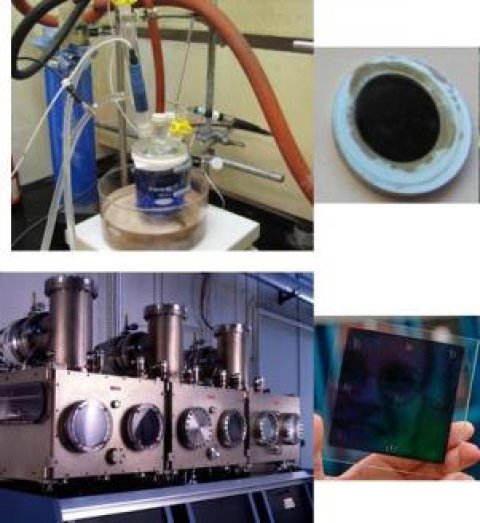

The research team explored materials with high melting temperatures, intrinsic oxidation resistance, high thermal conductivity, and low vapor pressure. The team performed the following steps:

- Conduct durability testing of candidate materials deposited on receiver metal substrates in conventional thermal furnaces, solar simulators, and on-sun systems to understand the degradation mechanisms and improve stability under realistic simulated environments.

- Apply successful coatings to tubular receivers and test the coatings on-sun as part of an integrated demonstration.

- Model these coatings for power tower applications and deposit them by physical vapor deposition, spin coating, thermal spray, and electro-deposition.

- Characterize the optical performance, material properties, and temperature stability.

- Consider surface modification techniques for performance enhancement and continue exploring lower-cost deposition methods for promising material systems that have been identified.

- Investigate novel multi-layered coatings predicted by models developed at NREL. A thermal spray process is concurrently under development to deposit promising materials on large areas, enabling inexpensive rapid application and reapplication on receivers in the field.

Innovation

Current coatings are not suitable for the high temperatures and oxidative environments needed for power towers. This project took an integrated approach to developing new materials with optimized optical properties and stability. Solution-based deposition methods allow rapid deposition and screening of coatings with intrinsic optical properties. Physical vapor deposition methods allow extremely fine control of the morphology, stoichiometry, and crystal structure, thereby controlling the resulting optical and thermal properties.

Publications, Patents, and Awards

- Gray, M. H., et al. "High temperature performance of high-efficiency, multi-layer solar selective coatings for tower applications." Energy Procedia 69 (2015): 398-404. doi:10.1016/j.egypro.2015.03.046

- Boubault, Antoine, et al. "Levelized cost of energy (LCOE) metric to characterize solar absorber coatings for the CSP industry." Renewable Energy 85 (2016): 472-483. doi: 10.1016/j.renene.2015.06.059

- Ho, Clifford K., and James E. Pacheco. "Levelized Cost of Coating (LCOC) for selective absorber materials." Solar Energy 108 (2014): 315-321. doi: 10.1016/j.solener.2014.05.017

- Ho, Clifford K., et al. "Characterization of Pyromark 2500 paint for high-temperature solar receivers." Journal of Solar Energy Engineering 136.1 (2014): 014502. doi: 10.1115/1.4024031

Learn about other concentrating solar power research.