Project Name: Solar Array Racking System

Funding Opportunity: Small Business Innovation Research and Small Business Technology Transfer (SBIR/STTR FY2019 Phase II)

SETO Research Area: Manufacturing and Competitiveness

Location: Cleveland, OH

SETO Award Amount: $1,205,000

Awardee Cost Share: N/A

Principal Investigator: Don Scipione

Planned Timeline: 2018-2021

-- Award and cost share amounts are subject to change pending negotiations --

This project team is designing an automated solar module racking system that can be produced from sheet metal on the installation site and withstand intense weather conditions, such as heavy snow and strong winds. The system is designed to have a lifetime of at least 30 years. Current solar module racking systems require preordering, transporting, inventory, and labor-intensive deployment. This new approach could reduce costs by up to 30% compared to conventional multicomponent racking systems that require more labor to produce and assemble.

APPROACH

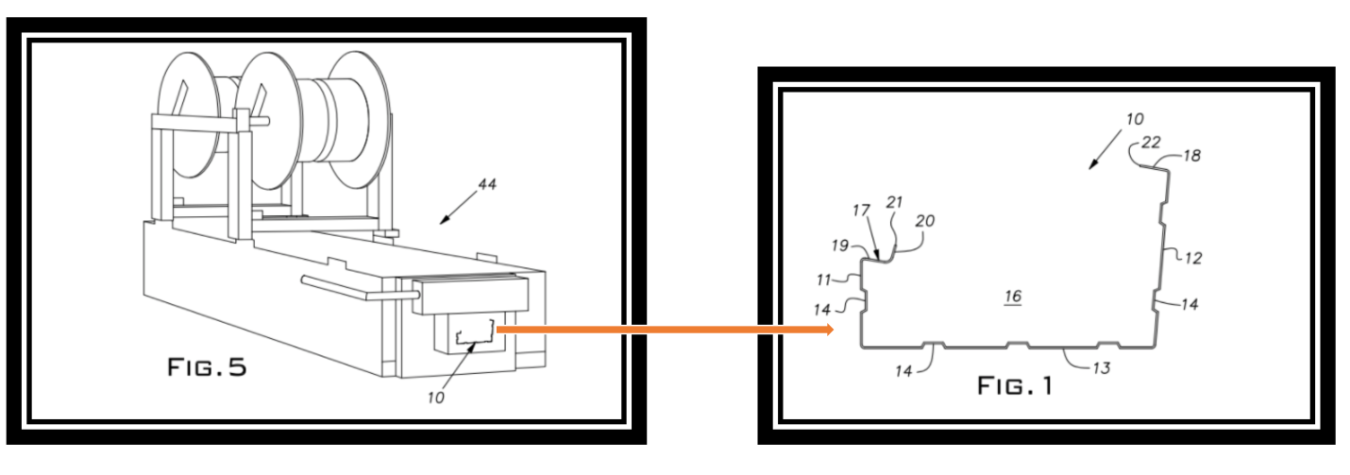

The project team is using mechanical analysis to design the racking system, which they will test in a wind tunnel using a model. An independent certification agency will test and verify the design. The certification will cover structural integrity under downward and updraft pressure, fire resistance, and electrical safety. The project team will develop a prototype roll-forming machine that will produce the racking system design, as well as raw material and coatings that will increase the system’s lifetime. Roll-forming is a manufacturing process used to produce gutters and metal roofing and siding.

INNOVATION

This project will use a roll-forming machine that makes a single-component, seamless rack from raw material as needed on site during installation. This will reduce the cost of racking materials, improve installation speed, and reduce overhead, such as ordering, transporting, and inventory.