Lower-Cost, Variable-Speed Electric Motor Improves Energy Efficiency

In 2011, the U.S. industrial, commercial, and residential sectors consumed ~13.5 quad of electricity, of which an estimated 7.8 quad (58%) was consumed by applications using electric motors in machinery; process cooling; and refrigeration, space heating, ventilation, and air-conditioning. As energy costs continue to rise, a critical task is reducing electricity consumption of induction motors using advanced power control technologies such as variable-speed drive. Because existing variable-speed motors cost at least four times as much as single-speed motors, they are currently used in only 5% of residential HVAC systems.

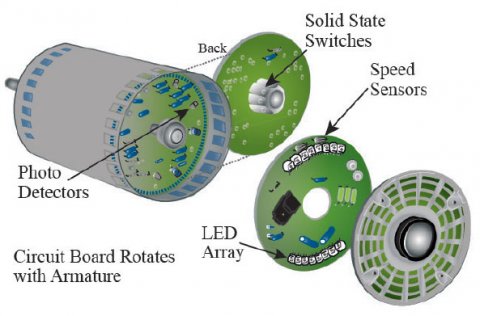

DynaMotors Inc., with the aid of a grant from DOE's Inventions and Innovation Program, developed a revolutionary low-cost, brushless, variable-speed motor technology that has solid-state switches on the rotating armature. These switches are optically controlled, thereby controlling motor torque and speed. The intended market was residential HVAC systems, but the technology can also be used in electric vehicles, aircraft, and factory automation. Existing HVAC systems use low-cost, low-efficiency, single-speed permanent split capacitor induction motors. These motors are cycled on and off as required by a thermostat. A variable-speed motor running continuously at a half speed uses 25% of the power to move the same amount of air. To achieve widespread market adoption in residential HVAC applications, the technology must be cost competitive with legacy equipment. DynaMotors addressed this issue and is selling its technology at 40%-50% less than existing variable-speed motors. Currently, Dynamotors' variable-speed drive motor is in the final stages of obtaining Underwriters’ Laboratory certification. A lower-cost version of the product, Comfortune™, has been introduced to compete in the residential HVAC market. The dynamotor is being applied to other industrial and commercial niche markets such as firefighting equipment.

Overview

- Developed by DynaMotors Inc.

- Commercialized in 2011.

Applications

Can be used for industrial and commercial applications using electric motors, including applications where reduced radio frequency interference (RFI) and electromagnetic interference (EMI) is required.

Capabilities

- Achieves compatibility with a wide range of equipment up to 1.25 HP, 2.7 ft-lbs torque at 1800 to 2600 rpm.

- Provides compact variable speed AC motor with integrated optical control.

- Offers plug and play combined motor and controller.

- Reduces installation time, cost, space, and errors.

- Provides compatibility with GFI breakers.

Benefits

Cost Savings

Reduces cost by eliminating the need for installing additional motor controllers and torque converters.

Environment

Provides quiet, RFI- and EMI-free operation using contactless optical commutation (brushless).

Product Quality

Achieves increased reliability and performance using an advanced electronic design with fewer components compared with traditional motor drives.

Contact

Bill Antestenis

(216) 292-7278

bantestenis@dynamotors.com

DynaMotors Inc.