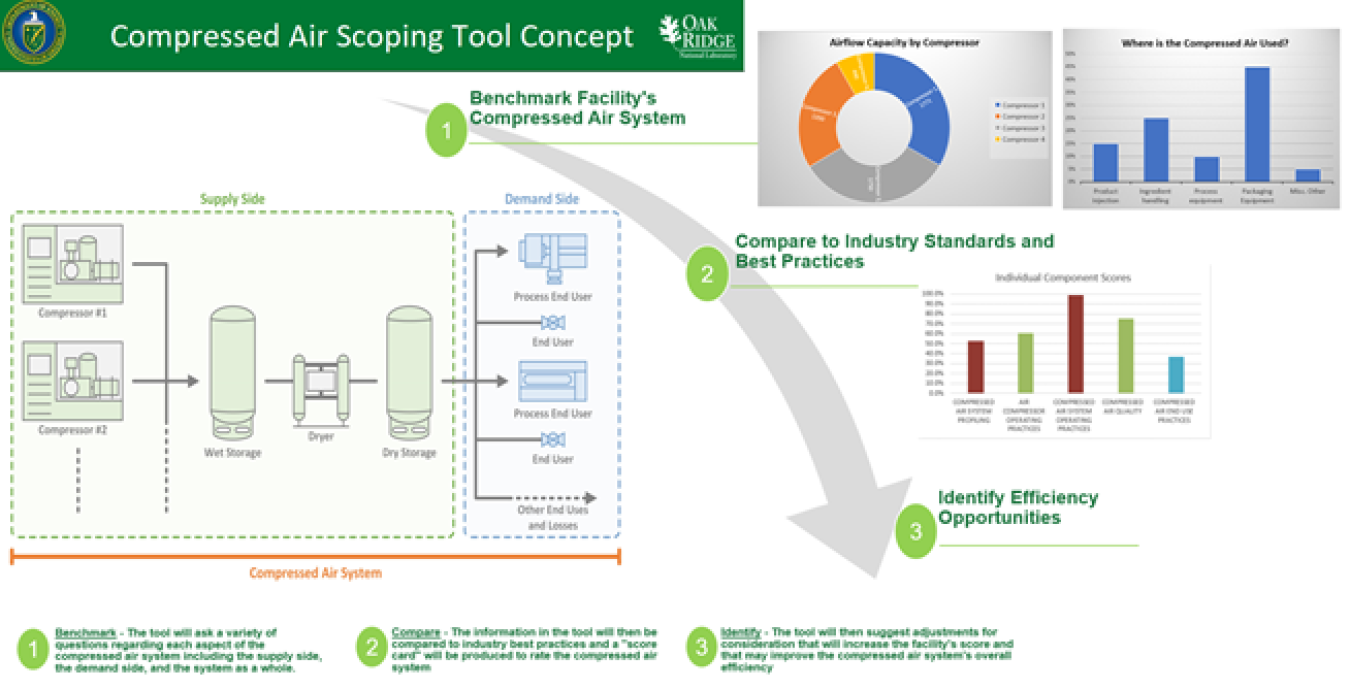

CA Scoping Tool Beta v1.0 is beta version of Compressed Air Scoping Tool in Excel format. It was developed at Oak Ridge National Laboratory (ORNL). CA Scoping Tool is a comprehensive tool designed for use by manufacturing plants or commercial buildings with significant compressed air energy use to help their sustainability teams:

- Understand the compressed air procedures in their plants;

- Compare their compressed air system operations to industry accepted best practices;

- Identify opportunities for compressed air system improvements

Features and Capabilities:

In many industries, compressed air is considered an additional utility: it is expensive and considered a requirement for modern-day manufacturing. Compressed air is widely considered the most inefficient process found in manufacturing and yet, one of the most prominent. CA Scoping Tool takes a systematic approach in evaluating the entire compressed air system, from supply side to demand side interactions. Thus, it helps management gain a better understanding of the system as a whole. Once the tool is filled out, opportunities for improvement are identified and enables maintenance efforts to prioritize compressed air efficiency measures. Results can also be used to establish a standard operating procedure and shared throughout a company to multiple facilities.

CA Scoping Tool evaluates a compressed air system by utilizing the users answers and comparing them to modern compressed air best practices that are widely accepted by the manufacturing industry. The result of the questionnaire is a system report card that will grade the system based on these best practices. The score given to the system will then lead to a list of suggestions to improve the score. Thus, the CA Scoping Tool is a “first step” that industrial manufacturing plants can follow to understand and improve their compressed air systems.

Acknowledgments:

CA Scoping Tool was conceived and developed by researchers at ORNL with funding from the U.S. Department of Energy’s Advanced Manufacturing Office. Several technical experts from the U.S. manufacturing industry contributed to the tool’s development by evaluating initial versions.

Development Team:

Alexandra Botts, Thomas Wenning, Sachin Nimbalkar

Oak Ridge National Laboratory

Leslie Marshall

General Mills

Industry Partners:

General Mills, General Motors, Compressed Air Challenge, NationalGrid

Advising and Outreach:

Mahabir Bhandari, Kiran Thirumaran, Wei Guo

Oak Ridge National Laboratory

Frank Moskowitz

Draw Professional Services

Sponsor:

Advanced Manufacturing Office, US Department of Energy

Languages:

English

Instructions for Users:

CA Scoping Tool is a downloadable, stand-alone tool provided in Excel format. It does not support import and export functionalities. Users should download the tool, save it as a master file, and create a new file each time they use the tool in their plants. After completing the data input, results can be printed or saved as a PDF file.

The tool files include:

CA Scoping Tool Beta v0.1.xlsm

CA Scoping Tool Beta v0.1_Sample Data.xlsm

Contact:

If you have any tool specific comments or questions, please contact Alex Botts (bottsam@ornl.gov).