Type I hydrogen storage cylinder. Photo from National Renewable Energy Laboratory

On-site hydrogen storage is used at central hydrogen production facilities, transport terminals, and end-use locations. Storage options today include insulated liquid tanks and gaseous storage tanks. The four types of common high pressure gaseous storage vessels are shown in the table.

| Type I | All-metal cylinder |

| Type II | Load-bearing metal liner hoop wrapped with resin-impregnated continuous filament |

| Type III | Non-load-bearing metal liner axial and hoop wrapped with resin-impregnated continuous filament |

| Type IV | Non-load-bearing, non-metal liner axial and hoop wrapped with resin-impregnated continuous filament |

Type I cylinders are the most common. Currently the costs of Type III and Type IV vessels are greater than those of Type I and II vessels. It is expected that with additional cost reductions in carbon fiber and improved manufacturing methods these technologies could ultimately cost less than the traditional metal Type I cylinders.

Cryogenic liquid hydrogen storage tank. Photo from National Renewable Energy Laboratory

Cryogenic liquid storage tanks, also referred to as dewars, are the most common way to store large quantities of hydrogen. Super-insulated low pressure vessels are needed to store liquid hydrogen at -253°C (-423°F). The pressure of liquid hydrogen is no more than 5 bar (73 psig). Regardless of the quality of the insulation, however, some heat will reach the tank over time and cause the liquid hydrogen to boil. The result is that hydrogen gas accumulates at the top of the liquid tank and causes the pressure inside the tank to increase. To keep the pressure from rising above the limits of the tank, the gaseous hydrogen must be vented from the liquid tank and either released or recompressed by a boil-off compressor to be stored as gaseous hydrogen.

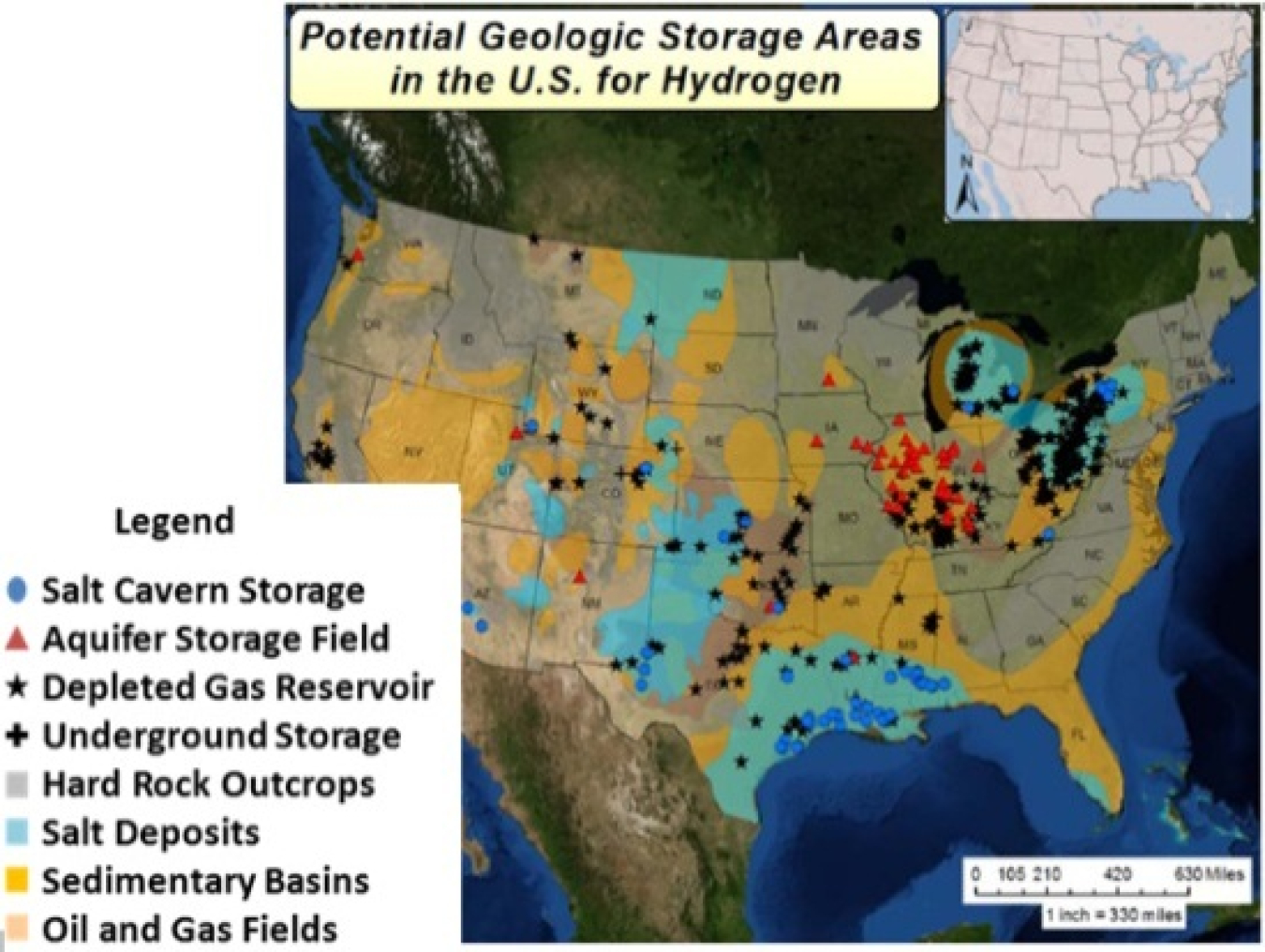

A national hydrogen infrastructure could require geologic (underground) bulk storage to handle variations in demand throughout the year. In some regions, naturally occurring geologic formations, such as salt caverns and aquifer structures, might be used, while in other regions, specially engineered rock caverns are a possibility. Geologic bulk storage is common practice in the natural gas industry and there are four existing salt caverns used for hydrogen storage today. The use of geologic storage for hydrogen used in fuel cell electric vehicles requires further investigation into the possible impurities that could be introduced by underground storage. The map on this page shows the potential U.S. locations for geologic hydrogen storage.1

Notes

1 A Life Cycle Cost Analysis Framework for Geologic Storage of Hydrogen: A User's Tool, Sandia National Laboratories.