In photoelectrochemical (PEC) water splitting, hydrogen is produced from water using sunlight and specialized semiconductors called photoelectrochemical materials, which use light energy to directly dissociate water molecules into hydrogen and oxygen. This is a long-term technology pathway, with the potential for low or no greenhouse gas emissions.

How Does it Work?

The PEC water splitting process uses semiconductor materials to convert solar energy directly to chemical energy in the form of hydrogen. The semiconductor materials used in the PEC process are similar to those used in photovoltaic solar electricity generation, but for PEC applications the semiconductor is immersed in a water-based electrolyte, where sunlight energizes the water-splitting process. Watch a laboratory-scale demonstration of this process performed at the National Renewable Energy Laboratory.

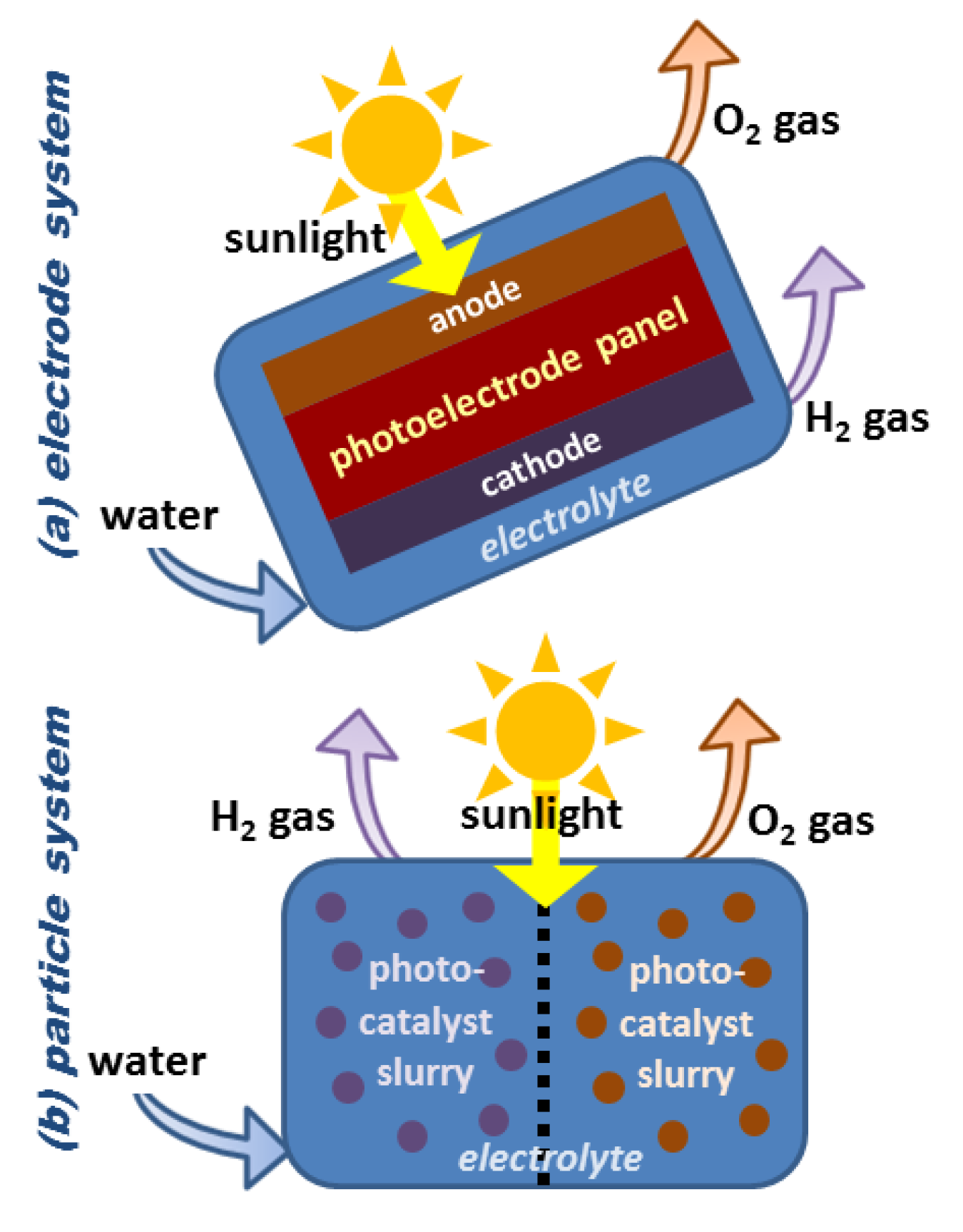

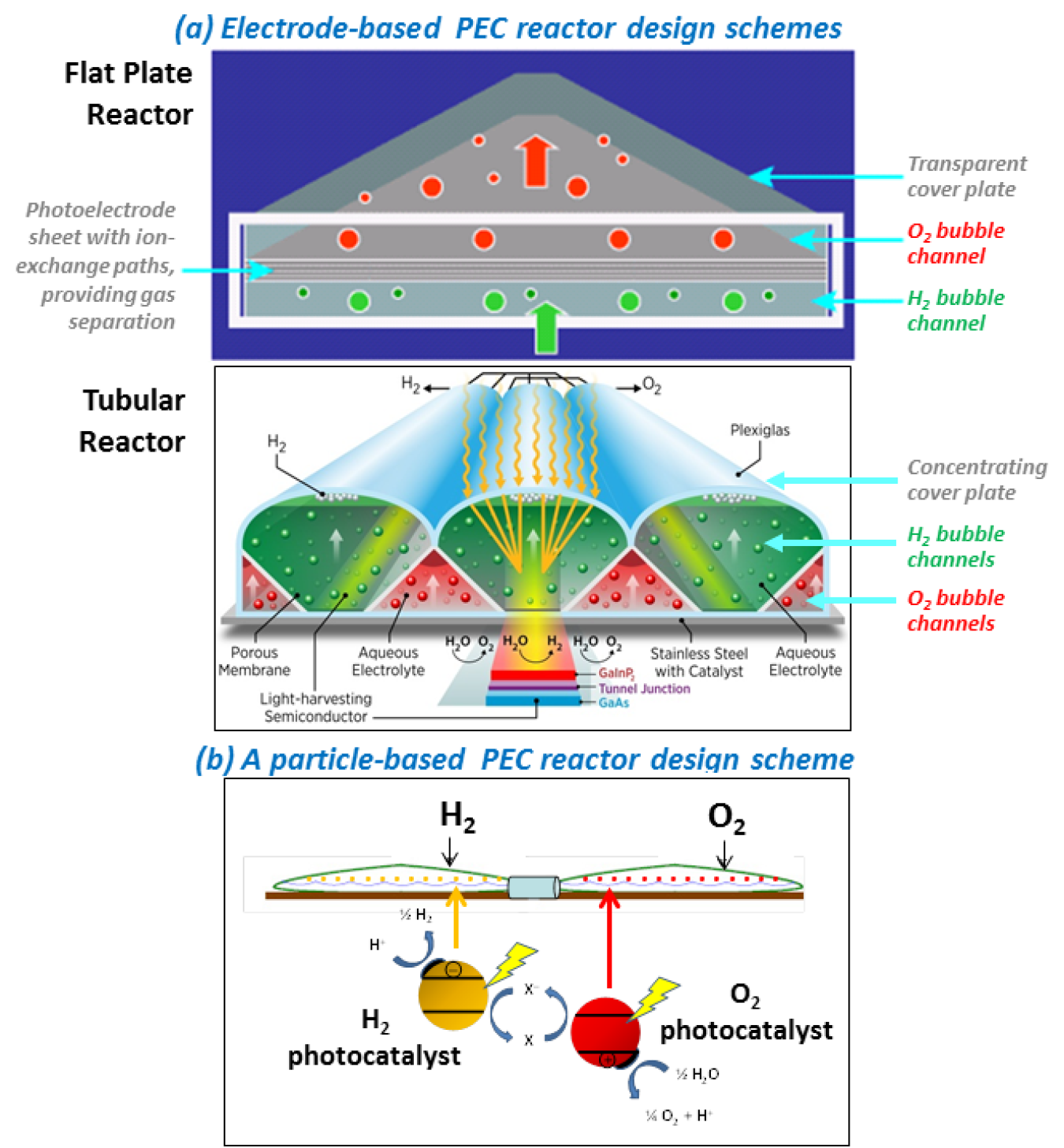

PEC reactors can be constructed in panel form (similar to photovoltaic panels) as electrode systems or as slurry-based particle systems, each approach with its own advantages and challenges. To date, panel systems have been the most widely studied, owing to the similarities with established photovoltaic panel technologies. Click on each figure title to see some different possible implementations of both the panel and slurry reactor concepts.

Figure 1 shows two different approaches to PEC solar hydrogen production reactors: (a) electrode systems similar to flat-plate photovoltaic panels; and (b) particle systems comprised of slurries of PEC semiconductor particles.

Figure 2 shows possible PEC reactor design schemes for (a) electrode systems, including a flat plate and a tubular reactor (providing moderate solar concentration onto one electrode strip); and (b) a plastic "baggie" covered dual bed particle reactor with wide-by-side photocatalyst slurries.

Learn more about photoelectrochemical hydrogen production systems in Technoeconomic Analysis of Photoelectrochemical (PEC) Hydrogen Production.

Why Is This Pathway Being Considered?

PEC water splitting is a promising solar-to-hydrogen pathway, offering the potential for high conversion efficiency at low operating temperatures using cost-effective thin-film and/or particle semiconductor materials.

Research Focuses on Overcoming Challenges

Continued improvements in efficiency, durability, and cost are still needed for market viability. Ongoing research and development of PEC materials, devices, and systems is making important strides, benefiting from strong synergies with contemporary research efforts in photovoltaics, nanotechnologies, and computational materials.

- Efficiencies are being improved through enhanced sunlight absorption and better surface catalysis.

- Durability and lifetime are being improved with more rugged materials and protective surface coatings.

- Hydrogen production costs are being lowered through reduced materials and materials processing costs.