Lead Performer: Oak Ridge National Laboratory (ORNL) — Oak Ridge, TN

April 8, 2019

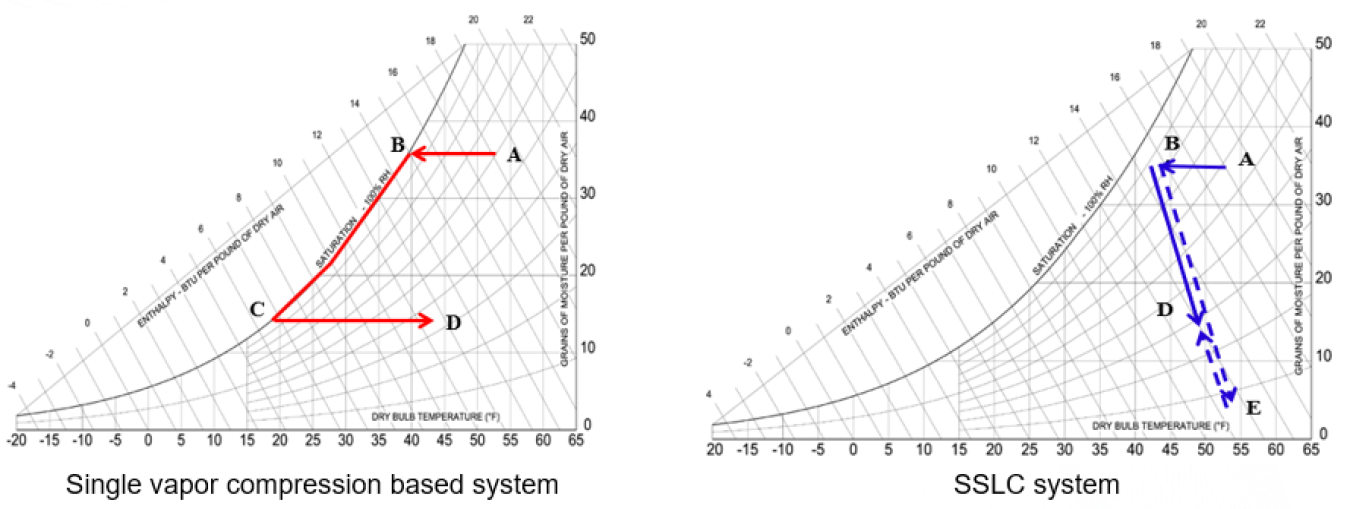

Figure 1: Distinction between conventional and SSLC operation.

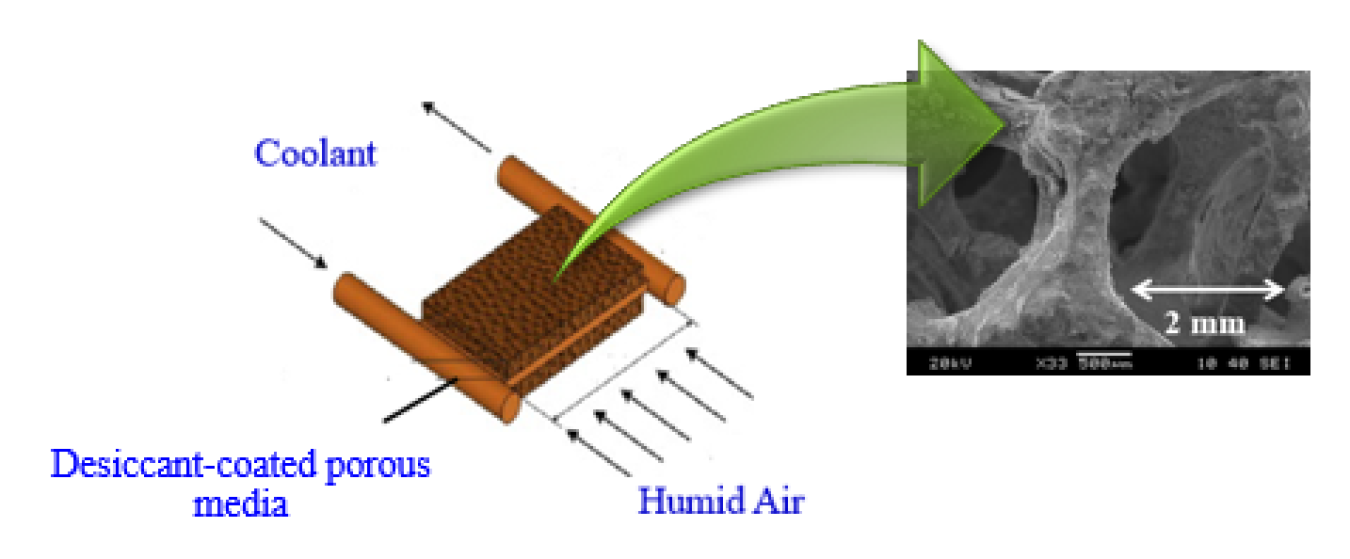

Figure 2: Desiccant coated metal foam heat exchanger cell.

Lead Performer: Oak Ridge National Laboratory (ORNL) — Oak Ridge, TN

Partner: Purdue University

DOE Total Funding: $1,250,000

Cost Share: $375,000

Project Term: October 1, 2019 — March 31, 2024

Funding Type: Lab Award

Project Objective

On average, about 33% of energy consumption is attributed to dehumidification processes. Separate sensible and latent cooling (SSLC) systems offer significant improvements in the overall performance of cooling/dehumidification systems compared with conventional vapor compression air-conditioning systems. Key to the energy efficiency of such systems is the performance of the heat and mass exchangers, which provide sensible cooling and dehumidification. The proposed work focuses on developing a novel technology to handle sensible as well as latent loads for buildings: a heat and mass exchanger deploying a metal foam as the substrate, coated with appropriate desiccant materials. ORNL is developing a highly efficient heat pump water heater technology using propane as refrigerant, where all critical components including compressor, heat exchangers and expansion valves are optimized to maximize the performance parameters. The technology would be able to provide at least 0.3 quads of energy savings per year. The energy savings will be realized by the improved UEF of the system (at least 30% improvement over baseline with UEF=2.5). Another merit for the project is reducing the environmental impact of refrigerants used by such systems which will be quantified by the total refrigerant charge and the characteristics of the refrigerants.

Project Impact

The improved dehumidification system, employing SSLC technology, offers a compact solution for moisture control in supply air, reducing infrastructure size by over 30%. It is anticipated to achieve a minimum 20% improvement in COP compared to traditional single vapor compression systems, resulting in a 40% cost saving compared to state-of-the-art alternatives. This innovation aligns with BTO's goal of achieving a 50% energy saving by 2030 compared to 2010 technologies.

Contacts

DOE Technology Manager: Payam Delgoshaei

Lead Performer: Kai Li