Chicago firm QCoefficient uses model predictive control (MPC) to pre-cool large commercial buildings, savings hundreds of thousands of dollars and tons of CO2.

June 23, 2016

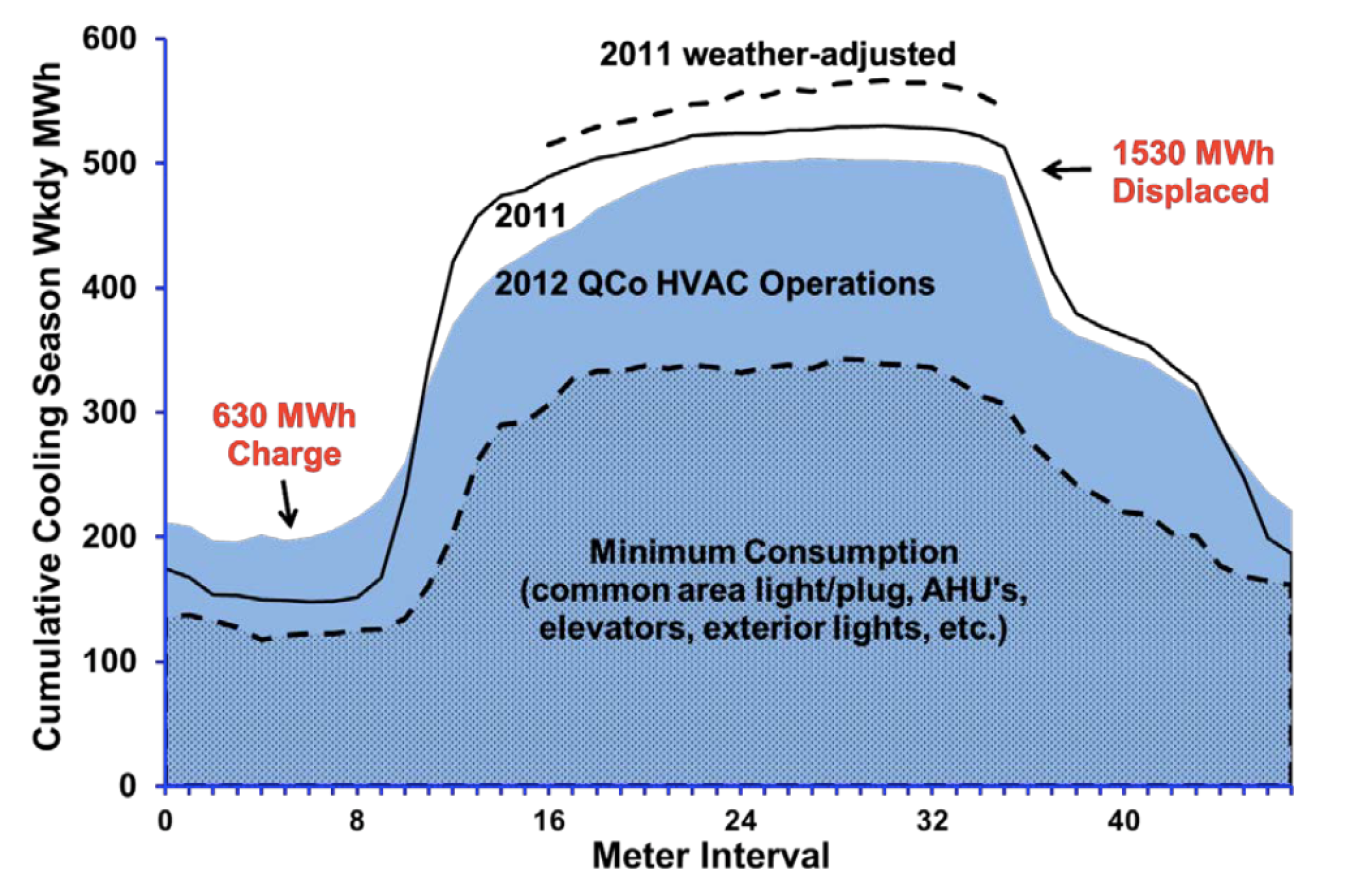

QCoefficient uses model predictive control (MPC) to pre-cool 13 of the 108 floors on Chicago’s Willis Tower. This figure shows cumulative energy use in 30 minute intervals between June 11 and September 28, 2012. QCoefficient’s optimized strategy replaced 1500 MWh of peak-time demand with 600 MWh of off-peak demand, saving approximately $250,000 and 900 tons of CO2 emissions in the process. Credit: QCoefficient.

The traditional, and still dominant, uses of energy modeling are all associated with building design. Architectural form and mass optimization. HVAC system selection and sizing. Code compliance. LEED or Green Globes certification. But energy modeling has exciting and impactful post-occupancy uses as well, and some of these, like model predictive control (MPC)—the use of models to explore operational alternatives in response to actual conditions and to optimize operations in real time—are quickly making their way from the whiteboard and into the marketplace.

One of the companies at the forefront of this emerging industry is QCoefficient, a Chicago firm that specializes in implementing demand response services for large commercial buildings. QCoefficient’s process is simple in concept. The firm contracts with an owner or management company to control some or all of the HVAC in a building. It then creates an EnergyPlus model of the building, calibrates it, and uses homegrown software to connect the model to the building’s energy management system and thermostats. Real-time information about local weather and building conditions keep the model true. The value proposition manifests during hot summer afternoons when electricity rates and demand charges peak due to spikes in air-conditioning use.

Using local weather forecasts and price signals from the grid, QCoefficient uses EnergyPlus simulations to develop an optimal pre-cooling strategy for the building. Specifically, it lowers zone thermostat setpoints in advance of the peak and cools the building during cheaper off-peak hours. It then leverages the building’s thermal mass—its structural elements, its contents, and the water in its pipes and tanks—to absorb heat during peak hours.

One of QCoefficient’s most visible clients and success stories is Chicago’s Willis Tower. QCoefficient controls 13 of the tower’s 108 floors, comprising 20% of its occupied space. In the summer of 2012, QCoefficient displaced 1,500 megawatt hours (Mwh) of peak energy use while increasing off-peak use by 600 Mwh. The 900 Mwh reduction—a typical home consumes 10 Mwh hours annually—combined with the shift from peak to off-peak use avoided 900 tons of CO2 emissions[1]. It also saved Willis Tower management approximately $250,000. These savings were achieved for three weeks of setup time and a setup fee of about $50,000—a rate of return of 500%!

“Hot weekdays present a great economic opportunity for thermal energy storage,” says QCoefficient Director of Engineering, Sandro Plamp, “especially in grid-congested cities. They are the least efficient for cooling as outdoor heat and humidity challenge day-time chiller performance and greatly increase the cooling load associated with fresh air ventilation They also experience the highest and most volatile electric prices. At this building, the incentives were magnified by participation in the Independent System Operators (ISO) economic and emergency demand response programs and by the very low, and sometimes negative, night-time prices that occur in the Midwest.”

With peak demand issues pushing to the forefront—peak demand determines utility generation capacity requirements, and plants that are brought online during peak times are typically a utility’s dirtiest and least efficient—applications like MPC will continue to grow in importance. And EnergyPlus will continue to evolve to meet their needs.

“We see a broad range of mechanical systems in the field,” says Plamp, “and we can readily select and model them in EnergyPlus. We frequently leverage the ability to interconnect water-based plant loops to model energy transfer across central systems. We also use the Energy Management System (EMS) feature to describe and model advanced supervisory control methods.”

Read more End-Use Breakdown blogs, or learn more about DOE's building energy modeling portfolio.

.....

[1] Emission calculations are based on regional annual averages (2012) and in absence of more granular emissions data are conservatively estimated. For example, this estimate does not account for the effect of displacing the marginal coal-fired generating plant from unit commitment.

Dr. Amir Roth

Dr. Amir Roth is the technology manager for BTO’s Building Energy Modeling (BEM) subprogram and has served in that role since 2010. From 2001 to 2010 he was first an assistant and then an associate professor with tenure of Computer and Information Sciences at the University of Pennsylvania in Philadelphia. He graduated magna cum laude with a B.S. in physics from Yale University and holds a Ph.D. in computer science from the University of Wisconsin—Madison where he won a dissertation award in 2001. He is a member of the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), and the International Building Performance Simulation Association (IBPSA).

Email Amir Roth ►