Dynamically Responsive Infrared Window Coatings

Lead Performer: Pacific Northwest National Laboratory - Richland, WA

Buildings

June 13, 2014

min

minute read time

min

minute read time

Caption

An oxygen plasma etcher is used to clean test substrates for window coatings.

Credit

Pacific Northwest National Laboratory

Caption

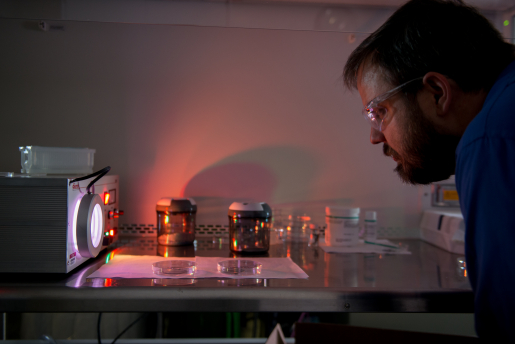

PNNL scientist Dr. Kyle Alvine checks on the progress of the plasma etch.

Credit

Pacific Northwest National Laboratory

Caption

PNNL scientist begins fabrication of a prototype window coating.

Credit

Pacific Northwest National Laboratory

Caption

Solution is deposited in preparation for spin-coating of a lab-scale nanostructured coating.

Credit

Pacific Northwest National Laboratory

Caption

PNNL scientist inspects a prototype nanostructured window coating.

Credit

Pacific Northwest National Laboratory

Caption

An oxygen plasma etcher is used to clean test substrates for window coatings.

Credit

Pacific Northwest National Laboratory

An oxygen plasma etcher is used to clean test substrates for window coatings.

Pacific Northwest National Laboratory

Caption

PNNL scientist Dr. Kyle Alvine checks on the progress of the plasma etch.

Credit

Pacific Northwest National Laboratory

PNNL scientist Dr. Kyle Alvine checks on the progress of the plasma etch.

Pacific Northwest National Laboratory

Caption

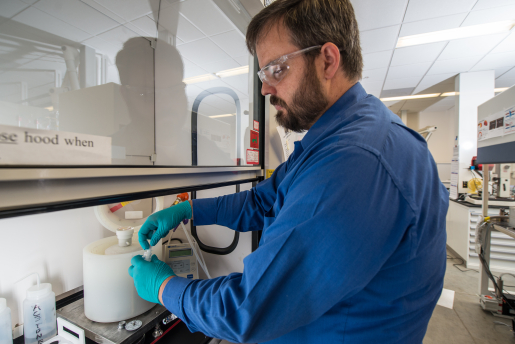

PNNL scientist begins fabrication of a prototype window coating.

Credit

Pacific Northwest National Laboratory

PNNL scientist begins fabrication of a prototype window coating.

Pacific Northwest National Laboratory

Caption

Solution is deposited in preparation for spin-coating of a lab-scale nanostructured coating.

Credit

Pacific Northwest National Laboratory

Solution is deposited in preparation for spin-coating of a lab-scale nanostructured coating.

Pacific Northwest National Laboratory

Caption

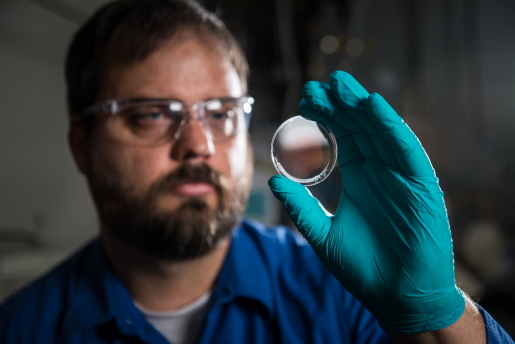

PNNL scientist inspects a prototype nanostructured window coating.

Credit

Pacific Northwest National Laboratory

PNNL scientist inspects a prototype nanostructured window coating.

Pacific Northwest National Laboratory

Lead Performer: Pacific Northwest National Laboratory - Richland, WA

Partners: PPG Industries - Pittsburgh, PA

DOE Funding: $750,000

Cost Share: $78,000

Project Term: October 1, 2013 – June 30, 2016

Project Objective

This project is developing a low-cost, visibly transparent, passively switchable dynamic infrared (IR) window coating that integrates IR-reflective sub-wavelength nanostructures in a buckling layer. The reversible buckling effect switches from transmitting to reflecting in the IR only as the window coating temperature increases. Two prototype films will be created: (1) a laboratory-scale (1 inch) dynamic IR-responsive coating with a near-infrared (NIR) transmission delta of 20% and a visible transmission of greater than 50%, as well as a temperature switching window in the 30°–90°C range; and (2) a bench-scale (6 inch) integrated buckling and sub-wavelength film with an average NIR transmission delta of 10%–15% (over 750–900 nanometers), an average visible transmission of at least 50%, and a temperature switching window in the 30°–90°C range.

Contacts

DOE Technology Manager: Karma Sawyer

Performer: Kyle Alvine, Pacific Northwest National Laboratory

Learn more