The Feedstock-Conversion Interface Consortium (FCIC) is developing fundamental understanding, tools, and strategies about construction materials to predict and address equipment wear.

Objectives

FCIC’s research objectives include:

- Gaining a fundamental understanding of failure modes and wear mechanisms

- Developing analytical tools/models to predict wear and establish material property specifications

- Identifying and demonstrating cost-effective mitigation strategies.

Approach

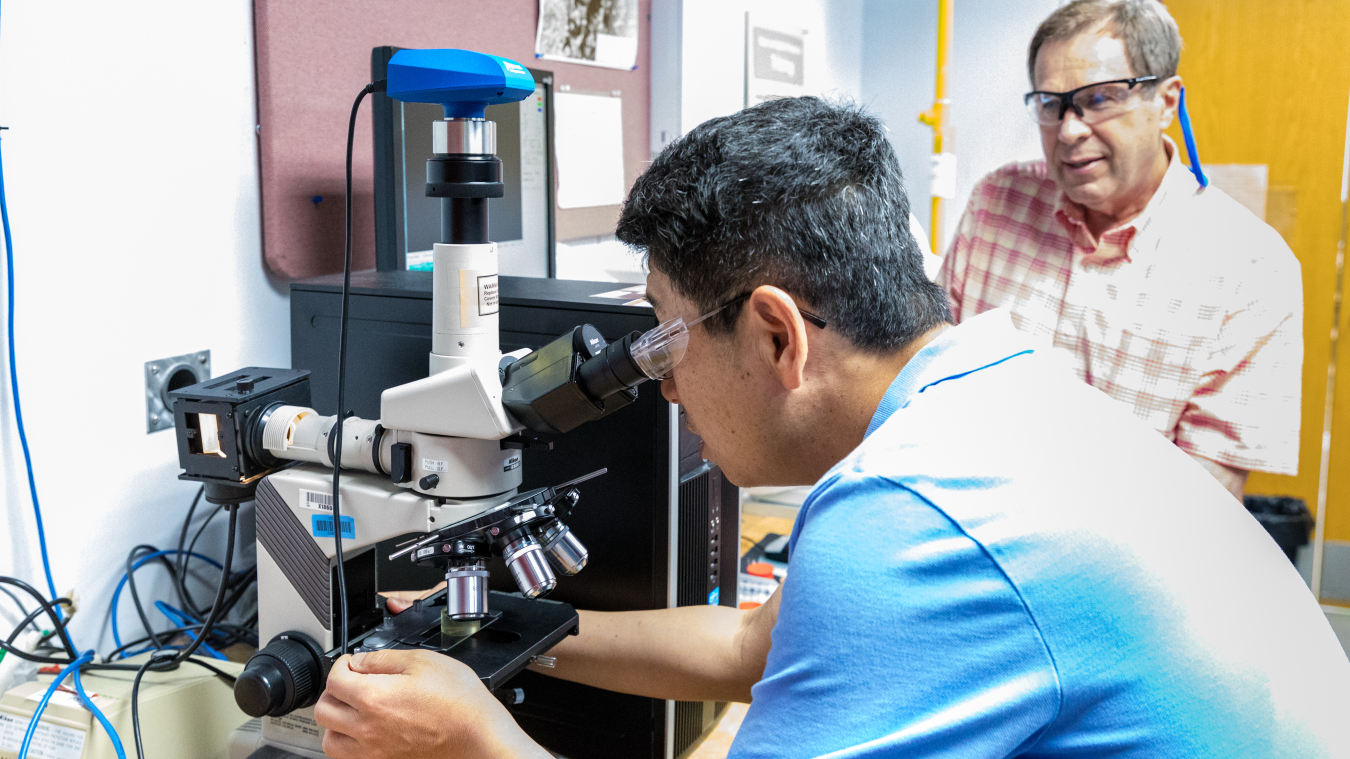

Scientists examine materials to determine the failure mechanisms of components used in biomass processing equipment. Photo from Carlos Jones/Oak Ridge National Laboratory.

FCIC’s research approach involves:

- Developing analytical tools/models to predict wear and establish material property specifications

- Selecting and evaluating candidate mitigations based on modeling and lab-scale testing

- Identifying top-performing mitigation strategies for process demonstration unit validation

- Sharing the fundamentals and mitigations with the biomass industry.

Outcomes

The expected outcomes from FCIC’s research include:

- Fundamental understanding of equipment failure mechanisms

- Validated models/tools to predict wear and degradation materials

- Identification and demonstration of mitigation strategies

- Free open-source tool to predict blade wear.

FCIC researchers recently developed an analytical model to predict the edge recession in knife-mill blades based on the chemical, physical, and mechanic properties of the knife-mill blades. Being able to predict how biomass properties will affect the lifetime of processing hardware helps process engineers make better decisions about capital purchases and preventive maintenance intervals. The ABRADE Model, based on fundamental abrasion models, is designed to allow GitHub repositories for open-source code.

Contact

For more information, contact the FCIC.

Other FCIC Research and Capabilities

Learn about all of FCIC’s research areas and capabilities/facilities.