New analysis outlines steps for turning piles of waste into a potentially powerful solution to lower one company’s carbon footprint.

September 20, 2022

Author: Zia Abdullah, Laboratory Program Manager, National Renewable Energy Laboratory

Read Zia's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

Pistachio Shells Are Piling Up—U.S. nut production is likely to increase 25% in the coming decades. This team of researchers offers creative solutions for managing agricultural waste ahead of the coming wave. Photo courtesy of Michael Leone, Wonderful Company.

In California’s Central Valley, not far from endless rows of fruit and nut trees, greying pistachio shells are heaped in giant mounds—and those mounds are getting bigger every year. Growing pistachios generates about 100,000 tons of waste annually in the United States. That number is likely to expand with growing appetites for protein-dense nuts and restrictions on burning and landfilling organic wastes.

That predicament had planners at The Wonderful Company—the leading global producer of pistachios—asking: What options do we have for dealing with nut shells?

Biomass Experts Step Up to the Mounds with a Powerful Solution

With expertise in biomass characterization and processing, the National Renewable Energy Laboratory (NREL) helped The Wonderful Company advance a clever solution: Turn those piles of pistachio shells into affordable, carbon-negative electricity.

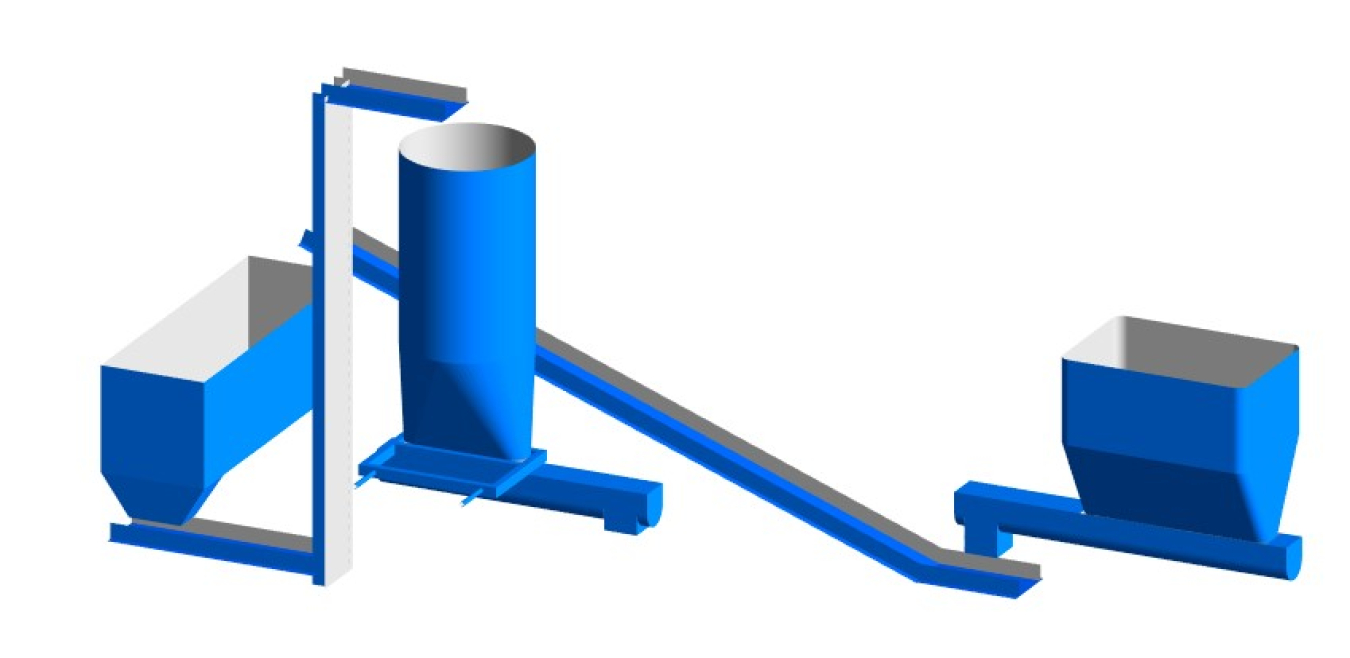

In partnership with Idaho National Laboratory, as well as technology companies V-Grid Energy Systems and Jenike and Johanson, the NREL-led team demonstrated how to clean, screen, process, and feed empty pistachio shells into small industrial gasifiers to create electricity. As a result, The Wonderful Company gained a novel solution for using its byproducts more viably.

Gasifiers Turn Pistachio Shells into Climate-Friendly Electricity

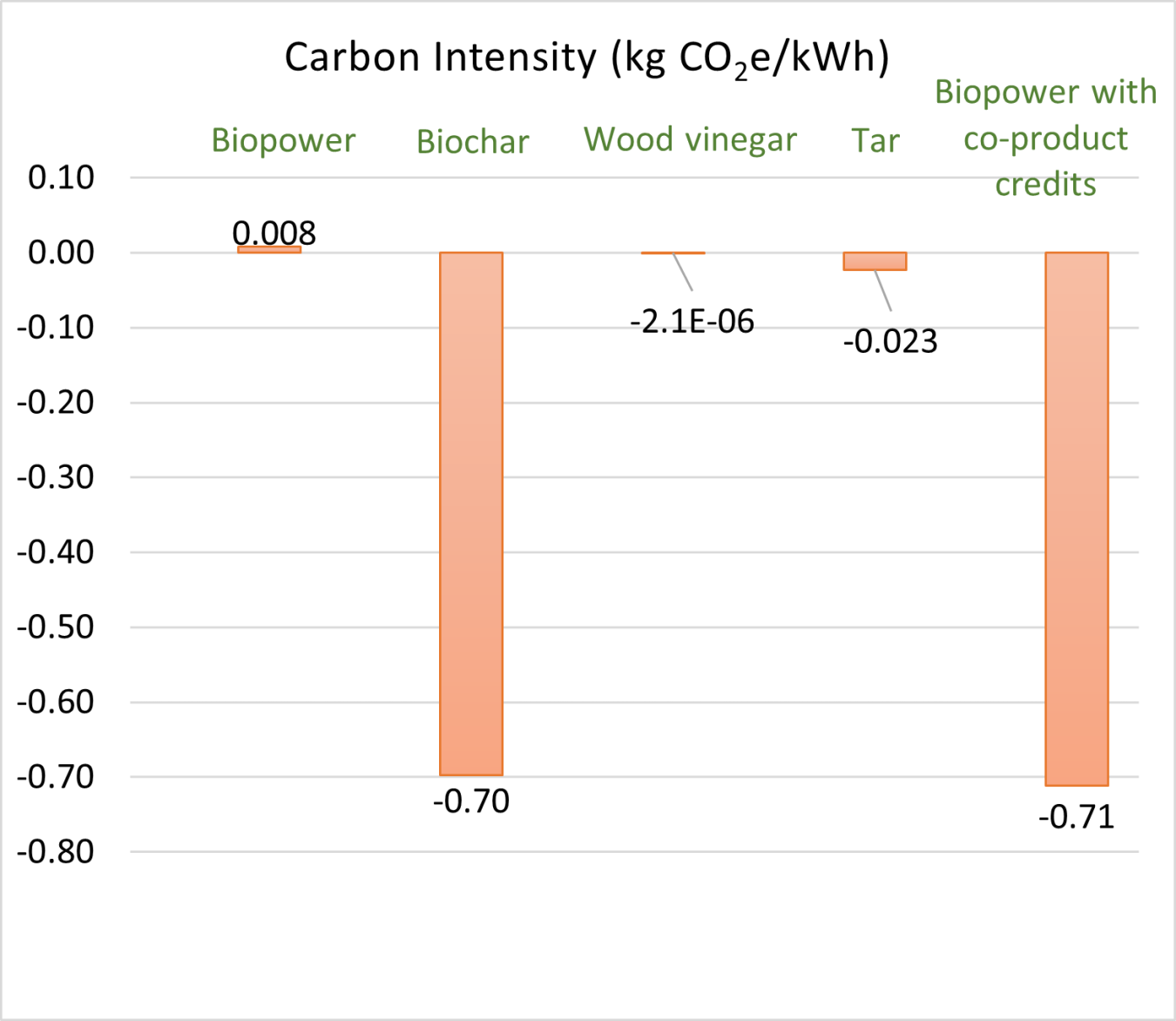

Carbon-Negative Electricity—According to NREL analysis, gasifying pistachio shells can yield carbon-negative electricity, made possible by permanently storing carbon in soil in the form of biochar.

Gasification is an industrial technology that can produce electricity from biomass and other feedstocks. When exposed to very high temperatures with an appropriate amount of oxygen and water, pistachio shells do not burn, but are instead transformed into “syngas,” which is a complex mix of hydrogen, carbon monoxide, and carbon dioxide gases. Syngas can be captured and combusted in an engine to create electricity.

After gasification, all that remains of the nut shells are bits of black, porous biochar—a charcoal-like substance often used at farms and gardens to boost fertility and sequester carbon as a solid in the soil. About 15% of the shells’ weight ends up as biochar.

Add it all up: Gasifying pistachio shells looks like a great solution for carbon-negative electricity:

- Pistachio trees absorb carbon dioxide during growth, offsetting a percentage of the emissions released during gasification and syngas combustion.

- Highly stable and almost entirely carbon, biochar permanently sequesters carbon in the ground, more than offsetting the remaining emissions.

Still—even with mountains of waste at hand—is it practical to make electricity from shells at scale?

Take a Handful: The Importance of Characterization

Into the Fine Details—Smaller bits of waste shell, called “fines,” can clog processing machinery. So, the NREL-led team outlined a cost-effective solution: Sieve the fines out first, turn them into pellets, and feed those pellets back into the larger system.

After its thorough characterization, the research team was able to offer The Wonderful Company precise recommendations on exactly how to process, handle, and ultimately gasify its piles of pistachio shells. For example, the team included recommendations on how to:

Gasifying pistachio shells at scale would mean processing, cleaning, sorting, and conveying hundreds of tons of shells a day. For the NREL-led team, understanding how to do that efficiently meant looking closely at the exact composition of those piles of pistachio shells.

Every handful of waste shells is different. Some have twigs, leaves, dirt, and even stray pistachios that didn’t make it to the packaging plant. Another might turn up grey and moldy shells that have spent weeks in the elements. Others could be clean and fresh—straight from the processing plant next door where the pistachios are shelled before packaging.

That variability had the researchers asking:

- How much moisture is in the shells?

- Are there impurities that could gunk up the gasifier?

- Will the shells need to be ground or sorted to keep from jamming conveyor belts and machinery?

- How many steps are needed to prep and transport the shells to a gasifier?

In search of answers, the team characterized the chemical, physical, and flow properties of several shell samples. They then used the data to design and optimize a system responsive to the variability in every handful of shells—all while reducing equipment, electricity, labor, and other costs.

Analysis Shows How To Get Shells to the Gasifiers

Conveying the Issue—The team gave The Wonderful Company a detailed design for processing and moving 4000 pounds of pistachio shells to gasifiers every hour. Image courtesy of Jenike & Johanson

- Preprocess by sieving out the smallest bits of shell and turning them into larger pellets that are more easily processed by the machinery,

- Handle the materials, including details on how to clean and transport with various conveyor belts,

- Tune the gasifiers to respond to unique characteristics of pistachio shells like moisture content and impurities.

After a 700-hour demonstration at a demo site, the process proved sound. The team had successfully developed a method for processing and utilizing waste nut shells.

Agricultural “Waste” No Longer Wasted—Simply Transformed

Waste is a growing challenge for the nut industry. Analysts anticipate a wave of new nut production on the horizon—an increase of up to 25% in the coming few years. States are also increasingly limiting the amount of organic waste allowed in landfills, with a goal of saving money and reducing landfill-related emissions.

As a result, farms and agricultural companies across the country are seeking alternative methods for dealing with waste while lowering their carbon footprints.

A core member of the U.S. Department of Energy Bioenergy Technologies Office Feedstock-Conversion Interface Consortium, NREL has expertise and capabilities suited to the whole range of agricultural waste materials. NREL was prepared to offer The Wonderful Company the analysis it needed to innovate its business processes, generate value, and dispose of company pistachio waste in a responsible manner.

Now, the team is working to generalize its findings for other kinds of agricultural waste.

That way agricultural “waste” is no longer wasted—it is simply transformed. Through careful analysis, characterization, and design, even the biggest pile of nut shells has the potential to become a powerful solution for lowering the carbon footprint of agriculture.

Dr. Zia Abdullah

Dr. Zia Abdullah is laboratory program manager for the National Renewable Energy Laboratory’s (NREL’s) Bioenergy Technologies Office program.

Zia has extensive experience and accomplishments in thermochemically and biochemically converting biomass to fuels and chemicals. His experience includes more than 25 years of industrial research and development in biomass conversion, as well as problem solving, new product development, business development, and project management.

Prior to joining NREL, Zia was chief technology officer at Versa Renewables LLC, where he developed and commercialized biomass pyrolysis and biopolyol technologies. Before Versa, Zia served as one of the Battelle Memorial Institute’s 11 fellows, leading the development of technology and commercial application for fuels, chemicals, and materials from the thermochemical and biochemical conversion of biomass. Prior to working at Battelle, Zia was a research advisor (fellow) at Weyerhaeuser Company, where he worked on challenges related to manufacturing and biomass valorization.

Meet our other bloggers ►

Return to Bioprose blog ►