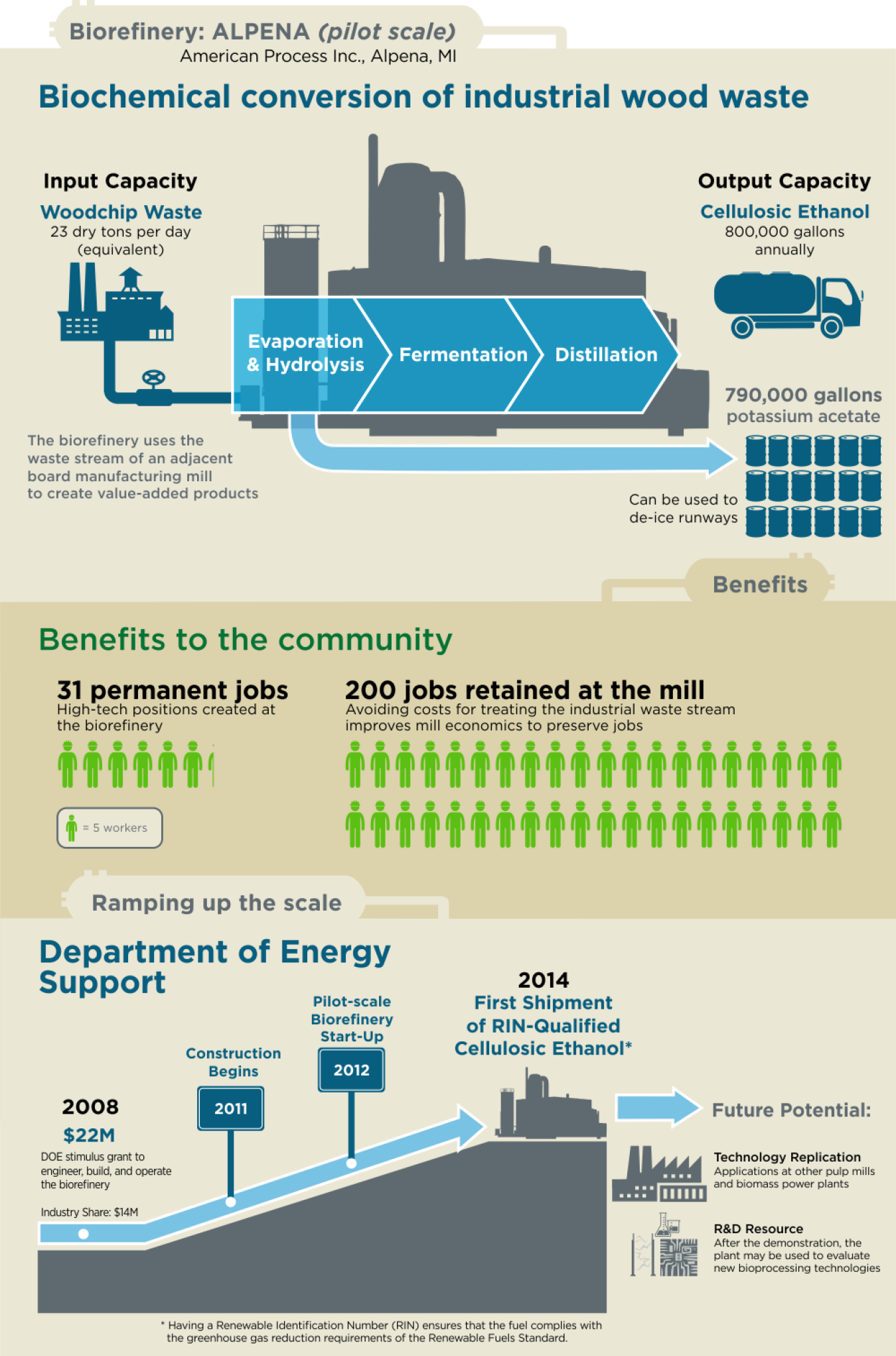

The American Process Inc. (API) Alpena Biorefinery converts the industrial waste stream from a neighboring board manufacturing mill into a cellulosic biofuel and by-product. API’s innovative conversion process has helped the mill to significantly reduce its waste treatment costs, increase its economic viability, and improve the job retention outlook for its 200 employees. In addition to assisting this major employer in Alpena, Michigan, API’s biorefinery has created at least 31 permanent manufacturing and technology-related positions. The biorefinery has been named a Michigan Center of Energy Excellence and designated a Michigan Renewable Energy Renaissance Zone.

The conversion process at the Alpena Biorefinery begins with the recovery of wood sugars from the mill’s liquid waste stream (about 23 dry tons per day). These sugars are then concentrated, hydrolyzed, fermented, distilled, and purified into cellulosic ethanol. Since this production process emits at least 60% less greenhouse gases (over the life cycle) than gasoline, [1] the biofuel is qualified to generate renewable identification numbers (RINs) under the Environmental Protection Agency’s Renewable Fuels Standard Program. API produced its first shipment of RIN-qualified cellulosic ethanol from woody biomass in April 2014—one of the first facilities in the country to do so.

The U.S. Department of Energy (DOE) awarded API a $22 million grant under the American Recovery and Reinvestment Act to get the demonstration project up and running. Beyond the demonstration period specified under the DOE award, API plans to continue operating the pilot plant under the terms of its agreement with the mill. The technology has already been commercially replicated at pulp mills and may be applied in biomass power plants. To further improve process economics, the Alpena Biorefinery is pursuing the simultaneous conversion of recovered acetic acid into potassium acetate, which may be used as a de-icing chemical on airport runways. In the future, the Alpena Biorefinery may also be hired by other innovators to evaluate emerging conversion technologies for the growing U.S. bioindustry.

API’s fully integrated biorefinery is one of many high-impact projects supported by DOE’s Bioenergy Technologies Office to accelerate the commercial production of economically viable, high-performance biofuels, bioproducts, and biopower.

This was an empty link: [1][1]Renewable Fuel Standard, “Energy Independence and Security Act of 2007” (Pub. L. 110–140)