Battery500: Progress Update

Office of Critical Minerals and Energy Innovation

May 19, 2020Lithium-ion (Li-ion) batteries have found wide-spread use in electric vehicles (EV) and grid-scale energy storage. This adoption is partially in response to the dramatic decrease in EV battery costs over the past ten years, from over $1000 per kilowatt-hour (kWh) to under $200/kWh. Increasing cell energy is one way to decrease cost even further, as a higher specific energy value will result in fewer materials needed for the same total battery energy. But it is difficult to increase the energy density beyond that of today’s cells, which are approximately 220 watt hours per kilogram (Wh/kg) using graphite anodes. Li-metal anodes deliver almost 10 times the storage capacity of graphite anodes, thus enabling much higher cell energies. However, Li-metal anodes suffer from poor cycle life (typically 10 cycles or less, compared to the 1000 cycle EV battery requirement).

Launched in 2017, the Battery500 Consortium is a multi-institution program working to develop next-generation Li-metal anode cells delivering up to 500 Wh/kg. The Battery500 team is composed of world-class scientists and engineers from four National Laboratories and five universities (Figure 1). Notably, two of the researchers on the team, Professor Stanley Whittingham of Binghamton University and Professor John Goodenough of the University of Texas at Austin, received the 2019 Nobel Prize in Chemistry for their work in Li-ion batteries.

Figure 1. Core team members of the Battery500 Consortium

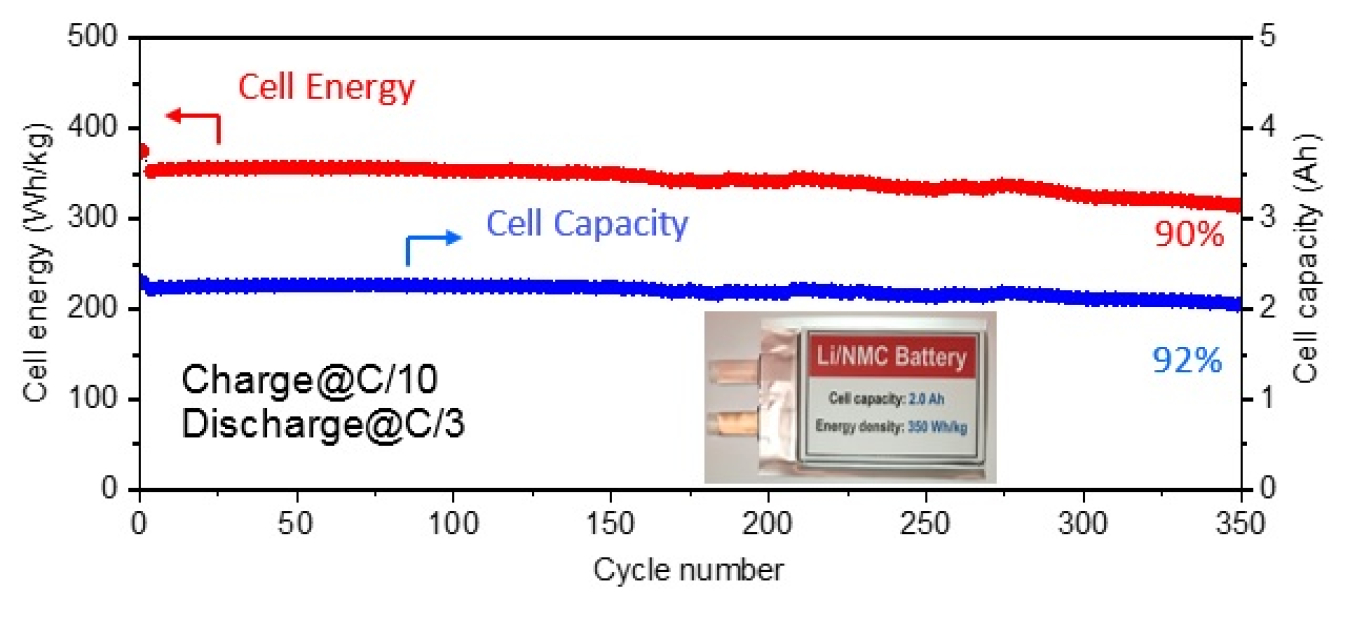

In the first two years of this program, the Consortium has made significant progress developing novel cell materials and integrating these materials in industry relevant pouch cells. At the beginning of the program, a Li-metal pouch cell delivered 300 Wh/kg but only cycled approximately 10 times. Currently, the team has increased that energy density to 350 Wh/kg and extended the cycle life to more than 350 cycles. Specifically, they developed new electrolytes with enhanced stability against Li-metal, optimized the use of thick cathodes against a thin lithium foil, and applied cell-stack pressure to extend cycling life.

Recent research on even thicker cathodes and more stable electrolytes shows a path to a 500 Wh/kg cell. Current focuses include increasing rate capability and extending cycle life.

Figure 2. Stable Cycling of 350 Wh/kg Li/NMC622 Pouch Cell