Student innovators across the country are pitching their ideas to industry leaders to solve some of energy's biggest challenges.

Office of Energy Efficiency & Renewable Energy

July 26, 2017By Erik Hyrkas, former EERE Communications team member

From power plant cooling systems to energy efficient window coatings, American university students are working hard to solve big energy problems.

But turning these technologies into new commercial products requires a lot more than time in a university lab. These aspiring student entrepreneurs often lack the business development skills, market exposure, and investor feedback needed to launch viable new businesses.

Nineteen student teams from across the country recently gathered in Austin, Texas to develop these skills and compete in the U.S. Department of Energy’s National Cleantech University Prize (Cleantech UP) business plan competition. After pitching their business plans to a panel of industry experts and investors, the teams received valuable support and feedback on their ideas.

Three teams emerged to win $100,000 in prizes and their new tech is just a glimpse of what American students can accomplish to solve some of energy’s biggest challenges.

This local power plant near MIT uses $5 million of water per year, and Infinite Cooling’s water capture technology could greatly reduce those costs.

First Prize: Infinite Cooling (Massachusetts Institute of Technology)

Infinite Cooling created a patent-pending technology that reduces power plant water consumption. It uses electric fields to charge and redirect steam, reintroducing water back to power plant cooling systems. This technology helps power companies conserve water and save potentially millions per year in water costs.

2nd Place: Grox Industries (University of Arkansas)

Each year, U.S. consumers lose 20% of their energy because of poorly insulated windows. Current glass coatings can help improve energy efficiency, but Grox Industries’ new nanomaterial, graphene-based window coating could save consumers even more. Not only does the company’s product, Helios, absorb more damaging ultraviolet light than current coatings, it is also adjustable, allowing the company to customize the coating for varying environments, climates, and altitudes.

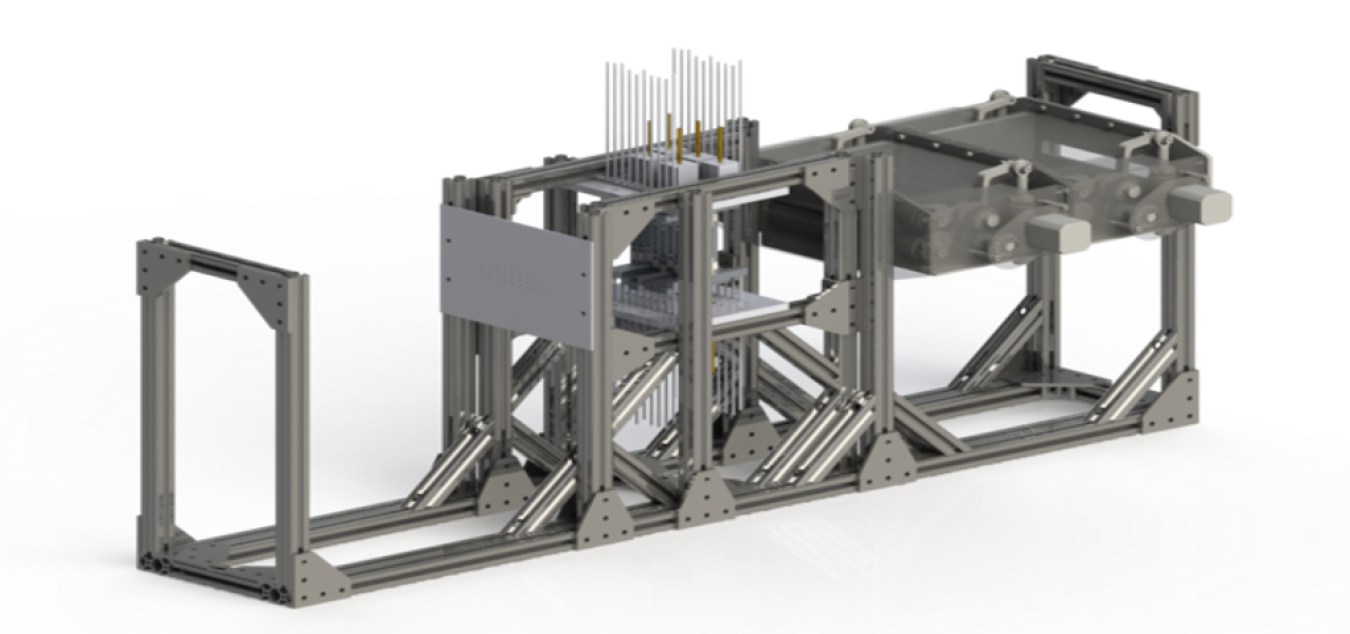

Georgia Institute of Technology’s WEAVE3D team invented a composite manufacturing technology that automates production of carbon fiber.

Third Prize: WEAV3D (Georgia Institute of Technology)

Composites have long been used in aerospace to improve fuel economy through lighter materials, but current manufacturing technologies are too slow and expensive to allow for composites to be economical in automotive applications. WEAV3D’s patent-pending, automated composite-forming machine has the potential to reduce the cost of manufacturing carbon fiber composites by 50% and increase production rates by 10 times.

Cleantech UP

This is the second Cleantech UP national competition since the program launched in 2015. The event brought together top performing teams from eight regional collegiate business plan competitions hosted by different universities and organizations earlier in the year. Since the annual competition started, participants have formed more than 200 ventures, created more than 115 jobs, and raised more than $120 million in follow-on funding.

Cleantech UP is part of the Tech-to-Market Program within the Office of Efficiency and Renewable Energy. Tech-to-Market strengthens the U.S. innovation ecosystem by eliminating common barriers that prevent market exploration of new energy technologies.