In honor of Black History Month, the Advanced Manufacturing Office is celebrating trailblazers whose work connects to the office’s ongoing research to improve energy and material efficiency, productivity, and competitiveness across the industrial sector. From inventions that revolutionized steam engines, lightbulbs, and more, we recognize their incredible work.

Learn more about their stories:

Dr. Dickson Ozokwelu: AMO Technology Manager and Chemical Reactions and Separations Expert

Born and raised in Nigeria, Dr. Dickson Ozokwelu was a widely recognized expert in chemical reactions and separations, as well as innovative ways to combine them. Dr. Ozokwelu served as an esteemed technology manager for EERE’s Advanced Manufacturing Office from 2001 until his passing in late-2019.

More than 95% of manufactured products rely on chemical goods. Dr. Ozokwelu had a passion for finding novel approaches to make these building blocks of modern life more energy and cost efficient. In the Advanced Manufacturing Office, Dickson’s colleagues will build on the legacy of his work for many years to come.

Elijah McCoy: Harsh Service Conditions

In 1892, Elijah McCoy invented lubricators to operate in the harsh environment of steam engines, helping this technology to revolutionize transportation and manufacturing during the late-19th and early-20th centuries.

Harsh environments remain a challenge for manufacturing. Today, EERE’s Advanced Manufacturing Office supports a range of projects to develop next-generation materials for high-temperature environments, high-pressure, highly corrosive, and/or radioactive operating conditions.

Lewis Latimer: Novel Uses of Carbon

In the mid-1800s, Lewis Howard Latimer invented and then patented the manufacturing process for a lightbulb using a carbon filament. By using carbon instead of paper, Latimer made early lightbulbs much more efficient, affordable, and durable.

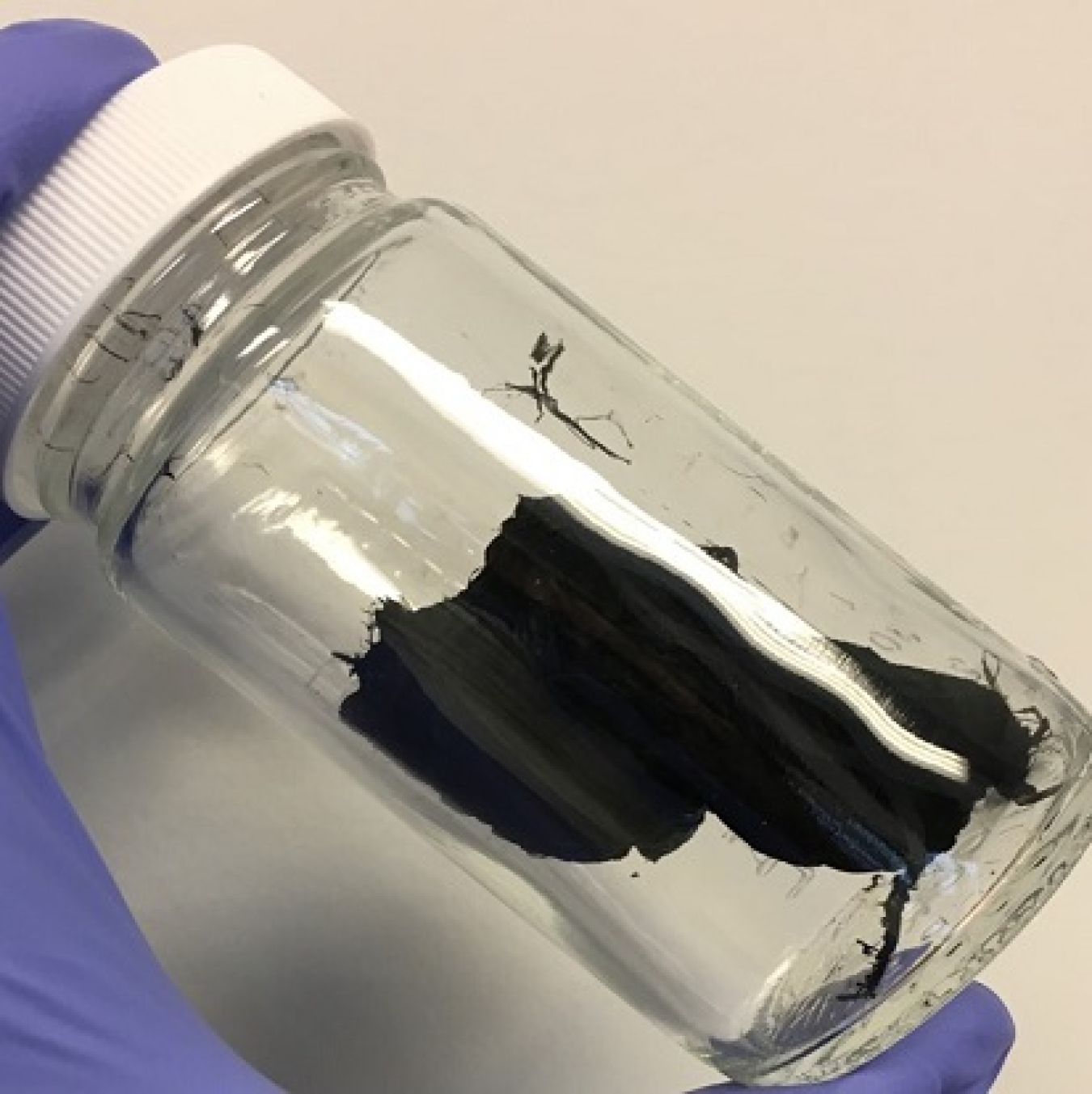

Today, work continues on new applications harnessing carbon’s special electrical conductivity properties at high temperatures, as discovered by Latimer. Projects supported by EERE’s Advanced Manufacturing Office are looking at innovative wires using carbon nanotubes to improve the performance, energy efficiency, and reliability of electrical machines across the manufacturing sector.

Follow the Office of Energy Efficiency and Renewable Energy on social media to get real-time updates on how trailblazers’ historical and current work ties to our initiatives: