The market for wide bandgap (WBG) power electronic devices is spreading due to increased awareness of the large energy savings and...

Advanced Manufacturing & Industrial Decarbonization

May 17, 2018

The market for wide bandgap (WBG) power electronic devices is spreading due to increased awareness of the large energy savings and system-level advantages that can be obtained. WBG technologies have the potential to reduce energy consumption and emissions in a variety of industries and is expected to grow about 33 percent per year. But while WBG technologies offer significant capabilities, the industry must overcome numerous technical challenges and reliability concerns. How can this industry manufacture devices at high volumes and low cost, while maintaining its workforce and competitive edge?

These challenges have put a strain on the industry with many U.S. companies unable to keep up with necessary facility upgrades to maintain production. In the U.S., about 70 six-inch silicon foundries have closed since 2000, causing high-paying technical manufacturing jobs to be sent overseas.

Investing in public-private partnerships and strategies to efficiently use abundant and low-cost energy resources in manufacturing is essential to creating and maintaining U.S. manufacturing jobs, sustaining the U.S. economy and maintaining manufacturing global competitiveness.

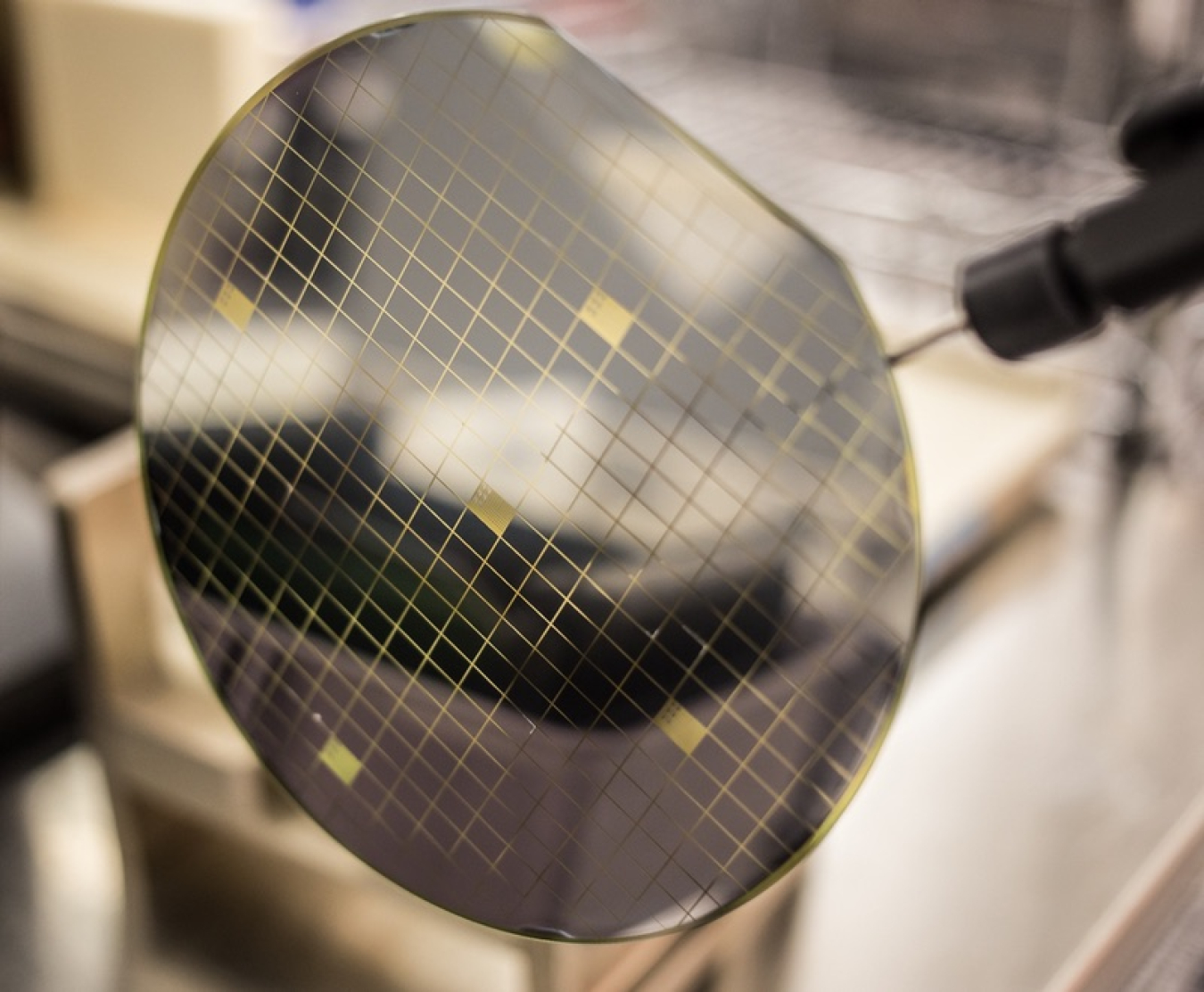

X-FAB, the world's leading foundry group for analog/mixed-signal semiconductor applications, is one company that knows all too well about the value of working to overcome adversity with help from a like-minded and supportive partner. A few years ago, it faced challenges with the production of silicon wafers used in computer chips. Though an emerging technology, silicon carbide requires cutting-edge facilities that, as technology advances, eventually lose their competitive edge.

Facing risks, X-FAB partnered with PowerAmerica, an Advanced Manufacturing Office Institute whose mission is to advance the larger scale adoption of wide bandgap semiconductor technology, to upgrade its facility in hopes of accelerating market adoption of its new technology. Headquartered at North Carolina State University in Raleigh, PowerAmerica is backed by $70 million in funding from the Department of Energy’s Advanced Manufacturing Office with matching funds from industry partners and the State of North Carolina.

With the support of the PowerAmerica Institute, X-FAB set out to accelerate the commercialization of SiC power devices by leveraging the economies of scale, automotive quality system and equipment set that have been established in its silicon wafer fabrication line. PowerAmerica also helped reconfigure the equipment at X-FAB’s 400-person foundry in Lubbock, Texas to be able to fabricate power electronic devices made from the more energy-efficient silicon carbide rather than silicon. And today, six U.S. companies are using the factory, with companies in Asia and Europe also expressing interest.

In 2016, X-FAB established a 6-inch silicon carbide foundry line fully integrated within its 30,000 wafers- per-month silicon wafer fab located in Lubbock, Texas. And last year, X-FAB Texas announced plans to expand its production of silicon carbide power devices making it the world’s first 6-inch silicon carbide foundry. The upgrade will create 50 new jobs and has an added value impact of $7.5 million.

These innovations, with investments from PowerAmerica, created a new business model that helps sustain jobs at the foundry, and also creates opportunities for other companies across the U.S. by substantially reducing the economic barrier to market entry.

PowerAmerica is accelerating the next generation of silicon carbide and gallium nitride power electronics with a strategic plan to reduce cost, improve reliability, demonstrate system insertion advantages, and strengthen the Power Electronics ecosystem. With continued investments and partnerships, it hopes to reduce U.S. energy use up to 2.2% by 2025 and grow the U.S. manufacturing workforce.

To date, PowerAmerica has funded more than 40 projects in the areas of foundry and device development, module development and manufacturing, commercialization applications and education and workforce development.

X-FAB is a charter member of the PowerAmerica Institute and is the first federally funded program in which it has participated in.