The U.S. Department of Energy (DOE) is soliciting proposals from the National Laboratories and industry partners under a lab call to strengthen domestic capabilities in solid-state and flow battery manufacturing.

Funds will be awarded directly to the National Laboratories to support work with companies under Cooperative Research and Development Agreements (CRADAs). The topics are:

- Topic 1: Developing Innovative Solid-State Battery Manufacturing Capabilities

- Topic 2: Developing Innovative Flow Battery Manufacturing Capabilities

All Topic 1 projects require a cost share of at least 20% of the total project costs. All Topic 2 projects require a cost share of at least 50% of the total project.

Interested industry partners should reach out directly to the National Laboratory contacts listed below about opportunities to collaborate.*

|

Capabilities: |

Processing and battery testing. Learn more. |

|

Contact: |

Ryan Ott, rtott1@ameslab.gov (Main) |

|

Argonne National Laboratory |

|

|

Capabilities: |

Processing, synthesis, diagnostics, multi-scale modeling, and failure analysis. Learn more. |

|

Contact: |

Venkat Srinivasan, vsrinivasan@anl.gov (Main); Zach Hood, zhood@anl.gov (Solid-State Batteries); Sue Babinec sbabinec@anl.gov (Flow Batteries) |

|

Brookhaven National Laboratory |

|

|

Capabilities: |

Characterization and battery testing. Learn more. |

|

Contact: |

Amy Marschilok, amarschilok@bnl.gov (Main) |

|

Kansas City National Security Campus |

|

|

Capabilities: |

Battery testing. |

|

Contact: |

Curtis Peterson, cpeterson3@kcnsc.doe.gov or Scott Jerabek, sjerabek@kcnsc.doe.gov (Main) |

|

Idaho National Laboratory |

|

|

Capabilities: |

Battery testing, characterization, and computational tools. Learn more. |

|

Contact: |

Anothony Nickens, anthony.nickens@inl.gov (Main); Erik Dufek, erik.dufek@inl.gov (Solid State Batteries) |

|

Lawrence Berkeley National Laboratory |

|

|

Capabilities: |

Processing, characterization, battery testing, and high-performance computing. Learn more. |

|

Contact: |

Robert Kostecki, R_Kostecki@lbl.gov (Main); Gao Liu, GLiu@lbl.gov (Solid-State Batteries); Vince Battaglia, VSBattaglia@lbl.gov (Flow Batteries) |

|

Lawrence Livermore National Laboratory |

|

|

Capabilities: |

Characterization, multi-scale modeling, and high-performance computing. Learn more. |

|

Contact: |

Marcus Worsley, worsley1@llnl.gov (Main) |

|

Los Alamos National Laboratory |

|

|

Capabilities: |

Battery testing, synthesis, characterization, and failure analysis. Learn more. |

|

Contact: |

Rodney Borup, Borup@lanl.gov (Main) |

|

National Energy Technology Laboratory |

|

|

Capabilities: |

Battery testing, multi-scale modeling, technoeconomic analysis, and solid oxide fuel cells. Learn more. |

|

Contact: |

Kirk Gerdes, kirk.gerdes@netl.doe.gov (Main); Harry Abernathy, harry.abernathy@netl.doe.gov (Solid-State Batteries); Greg Hackett, gregory.hackett@netl.doe.gov (Flow Batteries) |

|

National Renewable Energy Laboratory |

|

|

Capabilities: |

Processing, characterization, battery testing, and electrochemical modeling. Learn more. |

|

Contact: |

Matt Ringer, matthew.ringer@nrel.gov (Main); Andrew Colclasure, andrew.colclasure@nrel.gov (Solid-State Batteries) |

|

Oak Ridge National Laboratory |

|

|

Capabilities: |

Electrode engineering, battery testing, characterization, processing, and data analysis. Learn more. |

|

Contact: |

Bill Peter, peterwh@ornl.gov (Main); Jialin Li, lij4@ornl.gov (Solid-State Batteries); Robert Sacci, saccirl@ornl.gov (Flow Batteries) |

|

Pacific Northwest National Laboratory |

|

|

Capabilities: |

Battery testing, process; characterization, high-performance computing, database, and data analytics. Learn more |

|

Contact: |

Jie Xiao, jie.xiao@pnnl.gov (Main); Dongping Lu, dongping.lu@pnnl.gov (Solid-State Batteries); Wei Wang, wei.wang@pnnl.gov (Flow Batteries) |

|

Sandia National Laboratories |

|

|

Capabilities: |

Synthesis, characterization, battery component integration, battery testing, multi-scale modeling, and energy storage evaluation. Learn more. |

|

Contact: |

Carlos Gutierrez, cgutie@sandia.gov; CC: Irene Trujillo, itrujil@sandia.gov (Main); Kyle Fenton, krfento@sandia.gov (Solid State Batteries); Erik Spoerke, edspoer@sandia.gov (Flow Batteries) |

|

Savannah River National Laboratory |

|

|

Capabilities: |

Characterization and processing. Learn more. |

|

Contact: |

Will James, charles.james@srnl.doe.gov (Main) |

|

SLAC Accelerator Laboratory |

|

|

Capabilities: |

Processing, characterization, failure analysis, technoeconomic analysis, database, data analytics, and battery informatics. Learn more. |

|

Contact: |

Jagjit Nanda, jnanda@slac.standford.edu (Main) |

Ames National Laboratory

Capabilities

Flow Battery

- Materials/process scale-up; cathode and anode synthesis; cell/component manufacturing.

Crosscutting

- Materials/process scale-up; electrode synthesis; cell/component manufacturing.

Equipment

Flow Battery

- Direct Current (DC) and pulsed power supplies, potentiostats,

- Electrochemical working stations. Electrochemical surface finishing – electroplating and electropolishing,

- Acoustic mixers, a variety of mills for slurry and powder preparation,

- Heat-element furnaces, environmental furnaces, and microwave furnaces for materials synthesis and post-preparation electrode processing,

- Characterization equipment including particle size analyzer, surface area analyzers, NMR spectra, and electron microscopes.

Crosscutting

- DC and pulsed power supplies, potentiostats,

- Electrochemical working stations. Electrochemical surface finishing – electroplating and electropolishing,

- Solar simulators, a high-intensity light source to simulate concentrated solar illumination,

- High-purity alloy synthesis,

- Powder synthesis and processing,

- Characterization equipment including particle size analyzer, surface area analyzers, NMR spectra, and electron microscopes.

Facilities

Crosscutting

- Electrochemical working stations, materials synthesis lab Sensitive instrument facility (SIF), NMR lab

Argonne National Laboratory

Capabilities

Solid-State Battery

- Material synthesis and scaling capabilities including solid electrolyte (oxides, sulfides, halides, polymers, and polymer-inorganic composites) and cathode material.

- Sold State Electrolytes (SSE) membranes/interface layers and cathode laminate processing using roll-to-roll methods.

- Cell Prototyping with lithium metal, interphase layers, hybrid electrolytes (solid-liquid cells), and all-solid-state batteries.

- Analytical capabilities to examine materials, laminates and full cells spanning electrochemical, analytical, structural, and compositional characterization. Includes bulk and interface (exposed and buried) ex situ, in situ and post test.

Flow Battery

- Large volume synthesis of flow battery molecules including cathodes and anolytes and monomers and polymers for membranes,

- Flow membranes manufacturing using roll-to-roll methods including polymeric, composites etc,

- Functional coatings with thickness control,

- Range of analytical capabilities for compositional, morphological, degradation, and mechanical analysis.

Crosscutting

- Modeling and analysis:

- Technoeconomic analysis (BatPaC), life cycle (GREET), recycling (EverBatt, EverGrid), supply chain (GcMat), manufacturing processing (IMPACT),

- Synthesis modeling: co-precipitation, sintering, densification,

- Performance modeling: composition and morphology to predict performance and life.

Equipment

Solid-State Battery

- Material synthesis and scaling equipment:

- Flame Spray pyrolysis (up to 500 grams per hour/continuous)- oxide-based SSE,

- Dry processing of solid-state electrolytes (sulfides, oxides, halides),

- Solution-based synthesis of sulfides, oxides, polymers, and composites,

- Co-precipitation (100L)- oxide-based SSE, cathode materials,

- Tailor Vortex reactor- oxide-based SSE, cathode materials,

- Milling: planetary-, rotor beater-, roller-, cryo-, jet-, continuous bead- mill.

- SSE membranes/interface layers and cathode laminates:

- Wet deposition: slot-die coating (300 mm web) with corona plasma treater, Rotary screen printing integrated with R2R coater (300 mm web, patterned films), R2R flexographic printing (200 mm web, patterned films),

- Electrodeposition of lithium metal anodes w/ interphase layers,

- Electrospinning – polymers and oxide SSE (roll-to-roll process with 3m/min deposition rate, nm to µm fibers and scaffold)],

- Drying (UV, IR, multiple-zone dry air, photonic, integrated with R2R coaters),

- Atomic layer deposition (1 kg powder/batch, glove-box integrated),

- Chemical vapor transformation (1 kg powder/batch),

- Spray deposition (1-20 microns in thickness),

- Tape casting (inside of a glovebox),

- Slurry processing solid-state electrolytes and electrolyte/cathode composites,

- Mixing and dispensing: acoustic, continuous high sheer, centrifugal, and dual.

- Cell Prototyping:

- Pouch, 18650, coin, die, and custom-cells (e.g., pressure control)

Flow Battery

- Large volume synthesis of flow battery molecules:

- Heated-chilled reaction vessels up to 100 L for the synthesis and processing redox-active molecules (catholytes and anolytes),

- Synthesis of monomers and polymers for membranes.

- Flow membranes manufacturing:

- Benchtop (25mm to 200 mm sheet width and 10mm to 250 mm sheet length),

- Roll-to-roll (R2R) slot-die coating (300 mm web) with corona plasma treater capable of thin film deposition on solid and porous substrate with various pore size (e.g., 20-200 nm) and thicknesses,

- Rotary screen printing integrated with R2R coater (300 mm web, patterned films, thicker films than slot-die coating)

- R2R flexographic printing (200 mm web, patterned films),

- Ink formulation and synthesis (ink composition, rheological and hydrodynamic property design),

- Rotary web multi-nozzle co-electrospray – capable of fabricating dense and smooth single polymer or cross-link polymer membranes in 15-200 nm thickness range,

- Electrospinning or electrospray of composite membranes with anchored functional nanostructures – can improve nanostructure distribution,

- Scalable fabrication of porous substrates – serve as high mechanical strength supporting membranes,

- R2R multi-nozzle electrospinning (500 mm web width, 3 m/min maximum deposition rate) – tunability in porosity (µm pore size to completely pore close-out, thickness, and chemistry (e.g., hydrophobic, hydrophilic, chemical stability compatible with different electrolytes and separator membranes),

- Rotary web multi-nozzle co-electrospinning– capable of fabricating porous dual-fiber membranes with controllable water uptake and mechanical strength.

- Coatings:

- Atomic Layer Deposition (ALD)/ Molecular Layer Deposition (MLD) coatings for functionalized membranes and protection of end plates.

- Analytical capabilities:

- Cross over analysis (in situ electrochemistry, absorption, fluorescence, and NMR spectroscopy, and chromatographic analytics),

- Detection of degradation reactions in MEA and membranes at ppb scale (In situ NMR, UV-Vis, GC-MS etc.),

- Flux special and temporal distributions using synchrotron methods,

- Mechanical testing equipment for polymer membranes including tensile tester, rheometer, dynamic mechanical analyzer, and nanoindenter.

Facilities

Solid-State Battery

- Cell Analysis, Modeling, and Prototyping (CAMP) Facility - https://www.anl.gov/cse/cell-analysis-modeling-and-prototyping-camp-facility

Crosscutting

- Electrochemical Analysis and Diagnostics Laboratory Facility (EADL) - https://www.anl.gov/cse/electrochemical-analysis-and-diagnostics-laboratory-facility,

- Post-Test Facility - https://www.anl.gov/cse/posttest-facility,

- Electrochemical Discovery Laboratory (EDL) - https://www.anl.gov/jcesr/electrochemical-discovery-laboratory,

- Materials Engineering Research Facility (MERF) - https://www.anl.gov/aet/materials-engineering-research-facility,

- ReCell Center - https://recellcenter.org/,

- Advanced Photon Source (APS) - https://www.aps.anl.gov/,

- Center for Nanoscale Materials (CNM) - https://www.anl.gov/cnm,

- Argonne Leadership Computing Facility (ALCF) - https://www.alcf.anl.gov/.

Brookhaven National Laboratory

Capabilities

Solid-State Battery

- Electrochemical testing and analysis,

- In-situ and operando analysis of functioning batteries to track changes in oxidation state,

- In-situ and operando analysis of functioning batteries to track changes in crystallographic structure,

- Surface analysis including interfacial properties,

- Handling of samples within inert environments including dry room and glovebox capabilities,

- Advanced electron microscopy,

- Tomographic analysis of materials.

Flow Battery

- In-situ and operando analysis of functioning batteries to track changes in oxidation state,

- Electrochemical testing and analysis,

- Quantitative analysis of anolyte and catholyte composition,

- Characterization of current collectors,

- Characterization of separators.

Idaho National Laboratory

Capabilities

Solid-State Battery

- Battery testing (0-1000V, 0-440 kW),

- Mechanical performance verification and validation (V&V),

- Cell/component manufacturing (electrode and electrolyte),

- Computational tools,

- Characterization,

- System optimization including mechanical control,

- Electric field sintering science.

Flow Battery

- Membrane scale-up.

Crosscutting

- Density functional theory (DFT) and reactive force field molecular dynamics (Reax-FF MD) modeling,

- Advanced electrolyte model (AEM) for electrolyte optimization,

- Machine learning and physics-based failure mode identification and quantification,

- Material development.

Equipment

Solid-State Battery

- Multi-axis vibration stage for mechanical characterization (Bruel & Kjaer),

- Roll-to-roll electric field assisted sintering (continuous),

- 3-D printing of electrolyte material,

- S and NMC electrode scale up,

- Electrode/electrolyte tape-casting (100 cm2+),

- Gloveboxes and pouch cell scale-up for single layer pouch cells Optical and electron microscopy,

- Positron annihilation lifetime spectroscopy (PALS), nano-X-ray CT, and neutron-CT.

Flow Battery

- Assorted wet chemical and membrane casting equipment.

Crosscutting

- Battery testing,

- EIS.

Facilities

Solid-State Battery

- Electrochemical Processing & Electrocatalysis Lab,

- Electric Field Assisted Sintering Facility.

Crosscutting

- Battery Test Center,

- Energy Storage Materials Laboratory,

- Non-destructive Battery Evaluation Lab.

Lawrence Berkeley National Laboratory

Capability

Solid-State Battery

- Computational predictive simulations - materials project,

- A-lab (automated lab for new materials synthesis with robotic control),

- Cell/component fabrication,

- Ceramics processing,

- Cathode design for solid state cells,

- Fabrication, testing, and advanced characterization of liquid-free LLZO cells and halide cells via tape casting, with thin electrolytes <50um, and thick, porous electrode scaffolds >100um formed by freeze tape casting, phase inversion, or preformer burnout.

- Synthesis (solid state, hydrothermal/solvothermal, sol-gel, organic and polymer, combustion, spray pyrolysis, spray drying etc.),

- First principle based materials design,

- Polymer composite formation,

- Electrode design and fabrication,

- Slurry property evaluation,

- Battery testing,

- Computational tools, characterization, etc.,

- Scanning electron microscopy,

- Optical and vibrational spectroscopy,

- X-ray powder diffraction,

- Powder analysis,

- Thermal analysis.

Flow Battery Capability

- Computational predictive simulations - Materials Project,

- A-lab (automated lab for new materials synthesis with robotic control),

- Characterization of separator and membrane particles and slurries: ability to measure and visualize the particle size distribution of catalysts, the ability to characterize slurry flow properties, the ability to detect adsorption of molecules to substrates and catalysts, density measurement gauges, wetting angle gauges,

- Characterization of separator and membrane laminates: thickness gauges, ability to measure agglomeration size of catalysts and polymers, ability to measure the structure of polymers and the presence of specific functional groups, ability to measure water absorption levels and rates, ionic and electronic conductivity measurements, ability to measure the catalytic activity of catalyst layers.

- Cell design and construction: membrane fabrication, composite electrode fabrication for flow by and flow through systems,

- Stack assembly: for flow through hand flow by systems, porous flow-through electrode assembly,

- Cell testing capability: can run cells of varying size, from 1 cm2 to 50 cm2, and electrochemical equipment with a range of currents from 100 fA to 200 A and ultraviolet/visible light for state of charge determination,

- Modeling: Multi scale cell models of flow batteries, flow-through and flow-by.

Equipment

Solid-State Battery Equipment

- Tape casters (dense ceramics, or porous with preformer burnout): benchtop, mini in glovebox, and 1.5 meter pilot-scale with heated bed,

- Freeze tape casting (porous ceramics),

- Phase Inversion casting (porous ceramics and metals),

- Electrode calendering equipment,

- Dilatometers with controlled atmosphere,

- Custom programmable slurry casting robot with IR and convective heating capabilities and ability to integrate with confocal microscope and X-ray radiography beam line,

- Tube and box furnaces for air, inert, reducing atmospheres,

- Planetary ball mills, roller mills, attrition mills,

- Carver presses,

- Tabletop slot-die coater,

- Laser cutting,

- Vacuum infiltration of slurry into electrode scaffolds,

- Battery cyclers and potentiostat/galvanostats (Maccor, VMP3); EIS up to 7MHz,

- Impedance analysis equipment,

- Thinky mixers and dry mixing capabilities,

- Particle size analyzers,

- Brunauer–Emmett–Teller (BET) analysis,

- Thermogravimetric/Differential scanning calorimetry equipment,

- Optical spectrophotometers,

- Fourier-transform infrared (FT-IR) and Raman spectrophotometers,

- Scanning electron microscopes/energy dispersive X-ray spectroscopy,

- Inert atmosphere glove boxes,

- State-of-the-art wet labs equipped with high efficiency particulate air (HEPA) filtered hoods,

- X-ray powder diffraction with capillary spinner and hot stage,

- Schlenk line for air sensitive materials synthesis.

Flow Battery

- Lab scale Parr pressure reactors,

- For material and slurry characterization: particle size analyzer, scanning electron microscopes / energy dispersive X-ray spectroscopy, transmission electron microscopy (w/cryo), several rheometers, isothermal titration calorimetry, Micromeritics pycnometer, goniometer,

- Mixers and laminators: Planetary ball mills, roller mills, attrition mills, high-speed homogenizers, draw down coaters, spray coaters,

- For laminate characterization: Heidenhain thickness gauge, dynamic light scattering, ultra-small-angle X-ray scattering (USAXS), FT-IR/ATR, surface measurement system (SMS) dynamic-vapor sorption (DVS), BekkTech in-plane conductivity cell, and Scribner membrane test station (MTS) for transport coefficient measurements, rotating disk electrodes, Custom programmable slurry casting robot with IR and convective heating capabilities and ability to integrate with confocal microscope and X-ray radiography beam line,

- Stack assembly: several set-ups for flow-by systems that includes bipolar plates, flow through carbon layers, flow through cloth gas and liquid dispersion layers, and stack alignment devices,

- Several test stations: Biologic potentiostat, Solartron SI 1254 Freq. Response Analyzer, Maccor Battery Tester and UV -Vis.

Facilities

Crosscutting

Advanced Light Source (ALS), Berkeley

- An electron accelerator/storage ring that serves as one of the world’s premier sources of X-ray and ultraviolet light for scientific research ranging from advanced materials to protein crystallography and 3D biological imaging.

- Several techniques available at the ALS can be used to study solid electrolytes and devices containing solid electrolytes. These include:

- tomography, which allows 3D imaging of samples

- X-ray fluorescence (XRF) for elemental mapping, and

- Laue microdiffraction to analyze grain orientations, grain mismatches, and strain.

- Soft X-ray absorption spectroscopy (XAS) can be used to interrogate the chemistry of surfaces and interfaces with depth-profiling capabilities on the tens-of- nanometer scale.

- Ambient pressure X-ray photoelectron spectroscopy (APXPS) allows observation of changes in the chemistry at surfaces and interfaces at the angstrom level, in the presence of gases and/or upon heating or cooling in real time.

- The Foundry provides researchers with the tools to enhance the development and understanding of the synthesis, characterization and theory of nanoscale materials.

- The National Center for Electron Microscopy (NCEM), featuring cutting-edge instrumentation, techniques and expertise required for exceptionally high-resolution imaging and analytical characterization of a broad array of materials. The NCEM facility has 2 double-aberration corrected microscopes for atomic resolution imaging (the TEAM 0.5 and TEAM I microscopes).

- Testbeds can test heating, ventilation, and air conditioning (HVAC), lighting, windows, building envelope, control systems, electric car bidirectional charging and plug loads, in any combination and now with the addition of FLEXGRID include integrated DER and storage capabilities.

Lawrence Livermore National Laboratory

Capabilities

Crosscutting

Powder and ceramic processing, including high-energy ball mills, multiple mixers, and high-temperature tube furnaces.

Multi-scale modeling capabilities supported by Livermore Computing: LLNL computational scientists are supported by Livermore Computing (LC), which delivers a balanced high performance computing (HPC) environment with constantly evolving hardware resources and a wealth of HPC expertise in porting, running, and tuning real-world, large-scale applications. Currently LC delivers over 203 petaflops of compute power, massive shared parallel file systems, powerful data analysis platforms, and archival storage capable of storing hundreds of petabytes of data. This balanced hardware environment supports key collaborations between LLNL applications developers and LC experts. This involves the creation, production use, and performance monitoring and analysis of results of HPC parallel applications in a wide variety of scientific disciplines.

In addition to general access for development and debugging, researchers access allocations on these resources through several competitive internal programs. With these allocations, science and technology directorates sustain and enhance institutional capabilities to help ensure mission successes. Such efforts benefit the entire Laboratory by developing the expertise of the next generation of scientists and engineers who will, in turn, use these capabilities for continued growth of Laboratory programs. Furthermore, researchers with “work-for-others” (WFO) projects and external collaborators needing HPC access can purchase cycles on the Multi-programmatic and Institutional Computing systems.

Major systems include the heterogeneous 125-petaflops Sierra and its 23-petaflops unclassified sister system, Lassen, with a combined 164PB file system; Corona—which was increased to 11.5 petaflops to join the fight against COVID-19; several El Capitan Early Access Systems including: RZVernal at 6.9 petaflops, Tioga at 5.8 petaflops, and Tenaya at 4.4 petaflops; the nearly 6-petaflops Ruby; the 5-petaflops Magma; and additional large multi-core, multisocket Linux clusters with a variety of processor types, ranging from IBM PowerPC to Intel Broadwell processors. Our El Capitan testbeds feature HPE/Cray Slingshot interconnect technology and contain AMD Epyc Rome processors and AMD MI60, MI100, and MI250X GPU accelerators. We also have two cutting-edge AI powerhouses: the SambaNova accelerator for Corona and the Cerebras wafer-scale engine integrated into Lassen. In our systems totaling 203.1 petaflops of compute power, there are 22,530 NVIDIA Graphical Processing Units (GPUs) and over 2000 AMD GPUs across several of the platforms. In total, more than 16,000 nodes, nearly 700,000 cores, and 3.5 petabytes of memory are available across the production LC systems on two networks.

Computational scientists may also take advantage of several testbeds for evaluating next generation hardware and software. Researchers use these testbeds to investigate hardware advances in areas such as multi-core processors, networking technologies, I/O, GPUs, memory, and power-aware HPC (via a dedicated power lab), as well as investigations of software technologies. In addition, LC hosts production collaboration environments that facilitate the sharing of scientific data among international research groups, including the Green Data Oasis.

Several facilities house the simulation infrastructure at LLNL. The largest (LEED-certified) simulation facility offers 48,000ft2 and 85MW of power for systems and peripherals, and additional power for the associated 28,000-ton cooling system. Engineering and facilities staff maintain it in a physically secure environment. The balanced LLNL simulation environment includes Lustre multi-cluster file systems, HPSS-based archival resources, a high-speed Ethernet and InfiniBand networking infrastructure, advanced visualization resources, and a rich tool environment, as described in the facility section.

Equipment

Crosscutting

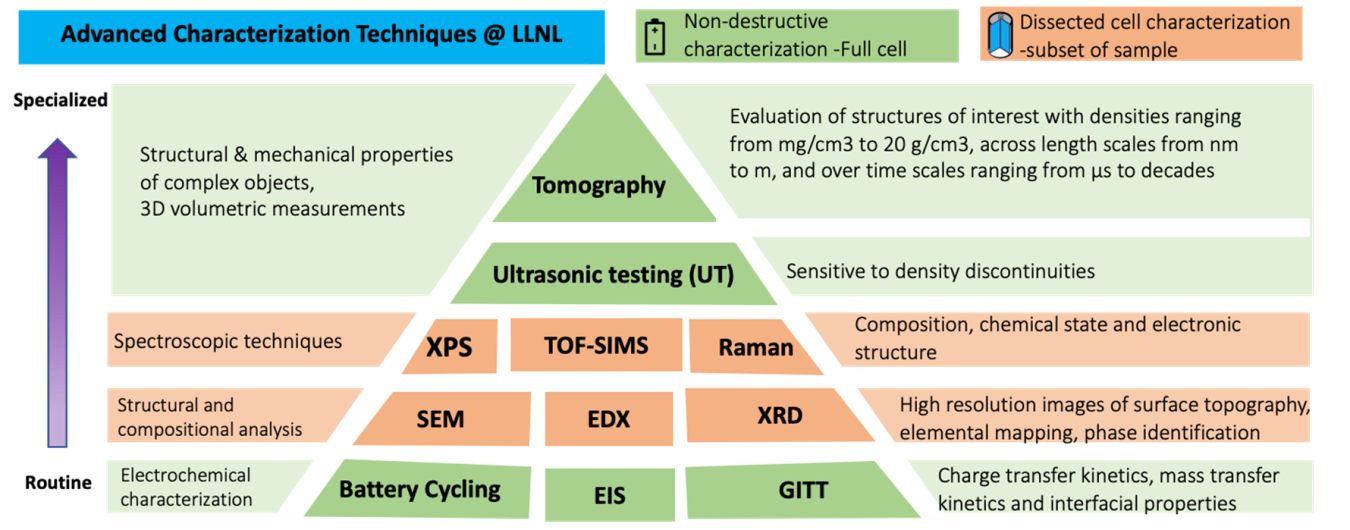

- Roll-to-roll coater, gloveboxes, potentiostats with electrochemical impedance spectroscopy, battery cyclers, and environmental chambers, as well as a suite of advanced characterization techniques highlighted in the figure below.

Facilities

Solid-State Battery

- Multiple laser labs with different types of lasers for laser processing of battery materials

- Battery labs with all necessary equipment for coin cell and pouch cell assembly.

Crosscutting

- Advanced Manufacturing Laboratory (AML) has both custom and commercial 3D printers, and we also have advanced characterization instruments, including X-Ray Diffraction (XRD), Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), X-Ray Photoelectron Spectroscopy (XPS) directly attached to a glovebox for inert sample handling, and a new high-resolution ToF-SIMS.

- Livermore Computing

High Performance Archival Storage

LC provides high-performance archival storage services via High Performance Storage System (HPSS). A world-class array of hardware integrated beneath HPSS includes disk arrays, tape subsystems, mover nodes, networks, robotics, and hundreds of petabytes of media.

File Systems

HPC systems require high performance storage, which LC provides in multiple forms: open-source Lustre, IBM Spectrum Scale, and the all-flash VAST. These systems are mounted across multiple compute clusters and deliver high-performance, global access to data.

LC Networking

LC’s simulation environment includes a software-defined 100G high-speed datacenter Ethernet networking infrastructure as well as InfiniBand SANs. LC employs InfiniBand and Omni-Path fabrics for high-speed interconnects. Testbed work includes evaluation of next generation networking equipment, including the HPE/Cray Slingshot interconnect.

Containerization

LC has deployed a selection of on-prem-cloud science-focused platform capabilities to enable persistent data services, HPC workflow tools, and machine learning frameworks. These services will include container management and orchestration and an object storage system.

Visualization facilities

LC runs two large visualization clusters—the CPU-only Tron on the SCF with a peak speed of 434 teraflops and the hybrid-architecture Pascal on the OCF with a peak speed of 1.9 petaflops—as well as visualization partitions on both Sierra and Lassen. LC supports RealVNC on login nodes and NICE DCV on batch nodes and operates several visualization theaters, ranging from auditoriums with PowerWalls to smaller collaboration spaces.

HPC Tool Environment

LC provides a stable, usable, leading-edge parallel application development environment that significantly increases the productivity of applications developers by enabling better scalable performance and enhancing application reliability. The tool environment includes high-performance compilers, debuggers, analyzers, editors, and locally developed custom libraries and application packages for software development. LC also provides a range of web-hosted tools: GitLab for repository hosting and continuous integration, JupyterHub for analytics in Python, and Confluence and JIRA for collaboration. LC enables users to exploit emerging technologies, while making software development within the compute center as easy as it is in the cloud.

- PRIMARY PRODUCTION COMPUTING PLATFORMS

Sierra and Lassen

Sierra, with its 125 petaflops peak, combines two types of processor chip— IBM’s Power 9 processors and NVIDIA’s Volta GPUs. Sierra is designed for more efficient overall operations and is a leading architecture for extreme-scale computing. Lassen shares Sierra’s unique architecture and is an unclassified system of 23 petaflops. Their smaller 1.5-petaflops sibling system is RZAnsel.

El Capitan Early Access Systems

Our 3 early access testbeds—RZVernal (4.1 petaflops), Tioga (3.7 petaflops), and Tenaya (2.9 petaflops)—combine 1 HPC- and AI-optimized 3rd generation AMD EPYC 64-core CPU with 4 purpose-built AMD Instinct MI250X GPUs.

Corona

An 11.5-petaflops heterogeneous Penguin Computing system comprised of AMD processors and AMD GPU accelerators. Corona has been upgraded for the fight against the novel coronavirus.

Ruby

A 6-petaflops CPU-only Supermicro cluster with a Cornelis Networks Omni-Path interconnect and 290 terabytes of memory.

Magma

A 5.3 petaflops Penguin Computing Relion system comprised of 752 nodes with Intel Xeon Platinum 9242 processors. The cluster has 293 terabytes of memory, liquid cooling, and an Intel Omni-Path interconnect.

Quartz

Quartz, a Penguin system, has 3,018 nodes, 344 terabytes of memory and a peak speed of 3.7 petaflops.

Jade

Jade, a Penguin Computing system, has 2,688 nodes and 343 terabytes of memory and a peak speed of 3.2 petaflops. It has Intel Broadwell processors. RZTopaz is a smaller 748-node cluster with the same architecture as Jade.

For a complete list of more than 20 production compute platforms supported by LC, see the Livermore Computing Systems Summary.

Los Alamos National Laboratory

Capabilities

Flow Battery

- Flow Battery Testing

- Membrane/Separator evaluation and failure analysis

- Expertise in air sensitive chemistry evaluation

- Electrolyte synthesis and manufacturing

- Membrane manufacturing (lab-scale with potential to bring to roll to roll casting unit).

Equipment

Flow Battery

- Multichannel Battery Cyclers

- High current (200 A) potentiostat

- Multiple potentiostat/bipotentiostats

- Gloveboxes for air sensitive battery chemistries

- Multiple test stands for aqueous and non-aqueous flow cell testing.

Crosscutting

- Roll to Roll casting/coating unit (planned installation September 2023) for membranes and electrodes.

Facilities

Flow Battery

- X-ray instruments (X-Ray Diffraction and X-Ray Fluorescence)

- Microscopes (Optical and scanning electron microscopy)

- Other characterizations facilities include Contact angle goniometer, mercury porosimetry, ultraviolet/visible, gas chromatography–mass, liquid chromatography–mass, and nuclear magnetic resonance).

Crosscutting

- Micro-CT instrument for electrode characterizations.

National Energy Technology Laboratory

Capabilities

Solid-State Battery

- Electrochemical testing and characterization

- Multi-scale, multiphysics electrochemical performance modeling

- Nanoparticle synthesis

- Materials evolution measurement and modeling (using conventional computing and HPC systems)

- Materials structure/function evaluations (including analytical microscopy and high fidelity digital reconstructions).

Flow Battery

- Modeling and computational analysis, especially related to electrodynamics and fluid flow modeling.

Crosscutting

- Technoeconomic Analysis

- Multiphysics electrochemical performance modeling

- Department of Energy Flagship expertise in Solid Oxide Fuel Cells and Solid Oxide Electrolysis Cells.

Equipment

Solid-State Battery

- Multichannel potentiostats/frequency response analyzers.

Flow Battery

- I-V test equipment, hardware-in-the-loop / cyber-physical systems.

Crosscutting

- System testing equipment, including facility grid tie-in

- Multichannel potentiostats/frequency response analyzers

- Potentiostat with 100 A power booster,

- Tape caster, spin coater, screen printer for electrode fabrication

- Automated ultrasonic spray coater

- Sputtering and atomic layer deposition chambers for thin film depositions, powder coatings

- High temperature furnaces for synthesis and thermal processing, including under reducing/inert atmospheres

- Characterization equipment: scanning electron microscope, transmission electron microscope, X-ray photoelectron spectroscope, and X-Ray diffraction equipment.

Facilities

Solid-State Battery

- Solid oxide cell test facilities, which may be purposed for battery testing.

Flow Battery

- Solid oxide cell test facilities, which may be purposed for battery testing.

Crosscutting

- Solid oxide cell test facilities, which may be purposed for battery testing.

National Renewable Energy Laboratory

Capabilities

Solid-State Battery

- Novel material processing for sulfide, halide, and polymer electrolyte,

- Large area full cell device fabrication using slurry casting and device testing,

- Novel suite of characterization methods including in-situ studying chemical and mechanical changes.

Flow Battery

- Rapidly evaluate novel electrolyte solutions performance in NREL’s testing lab,

- Design and fabrication of RFB cells/stacks with high performance/low cost,

- BOP system design and prototype fabrication/testing.

Crosscutting

- Extensive electrochemical modeling of diverse systems including li-ion and fuel cells.

Equipment

Solid-State Battery

- Several glove boxes dedicated to handling sulfide based solid electrolyte materials and lithium metal anodes. Glove boxes are set-up for slurry processing of solid electrolytes with various casting and calendaring equipment.

- Lithium vacuum deposition chamber,

- Presses and custom cell fixtures for testing all solid-state cells at coin and pouch cell level at controlled stack pressure (1-100 MPa).

Flow Battery

- Flow loop for testing small redox flow batteries including both aqueous and organic redox flow batteries.

- An SLA 3D printer, benchtop CNC machine, polishing wheel, and benchtop two-axis mill printer for rapidly prototyping plastic stack component

Crosscutting

- Characterization: In-situ virtual electrode XPS measurements, AFM transport imaging, nano-indentation, nano-CT, and X-ray Absorption,

- High-throughput laser processing system for investigating novel 3D architectures,

- Thermal testing: Large environmental chambers and isothermal calorimeters.

Facilities

- Significant glovebox and facilities for solid-state device fabrication. Please see: https://www.nrel.gov/storage/electrochemical-energy-storage.html

- Small-scale testing lab setup for redox flow batteries (both aqueous and organic). https://www.nrel.gov/storage/electrochemical-energy-storage.html

- Lab and cycler channels for testing battery prototype systems at 1-100 kilowatt range.

Oak Ridge National Laboratory

Capabilities

Solid-State Battery

- Simulation of sintering process

- Nondestructive tools to evaluate the component and cell quality and properties

- Raw materials and slurry dispersion

- Electrode engineering; Performance testing, Electrode-curing processes for polymer membrane

- Polymer/ceramic membrane and composite cathodes

- Lithium anode lamination; Li evaporation, E-beam and gamma-radiation exposure for in situ polymerization and crosslinking

- Advanced methods for lithium metal deposition and lamination

- Capabilities for testing flow batteries and their components including extensive membrane, electrode and cell methods both standard and specialized

- In situ characterization to facilitate standardization in processing and testing for large scale validation and quality assurance

- Capability in polymer disciplines as well as adhesion and other mechanical aspects

- High-throughput, large-scale additive manufacturing to customize cell parts for new architectures

- Scalable carbon fiber bundle fabrication

- Atmospheric pressure plasma treatment in a roll-to-roll line to optimize surface energy (carbon fiber and polymer coating layers)

Flow Battery

- Capabilities for testing flow batteries and their components including extensive membrane, electrode and cell methods both standard and specialized

- In situ characterization to facilitate standardization in processing and testing for large scale validation and quality assurance

- Capability in polymer disciplines as well as adhesion and other mechanical aspects

- High-throughput, large-scale additive manufacturing to customize cell parts for new architectures

- Scalable carbon fiber bundle fabrication

- Atmospheric pressure plasma treatment in a roll-to-roll line to optimize surface energy (carbon fiber and polymer coating layers)

Crosscutting

- Roll-to-roll (R2R) deposition/coating (coatings including single sided, double sided, single layer, simultaneous multiple-layer, continuous and intermittent coatings)

- Manufacturing electrode architectures and configuration to improve electrochemical performance

- Synthesis and advanced sintering processes

- Advanced characterization (including in-situ/operando detection for synthesis, sintering, microstructure evolution and defect formation)

- Dry room facilities

- New feedstocks and processes for carbon, polymer, and fiber reinforced composite material systems

Equipment

Solid-State Battery

- Slot-die coating

- Tape casting and screen printing

- Ceramic processing; Plasma deposition

- Fast sintering; Lithium deposition, Interface engineering and cell manufacturing

- Laser caliper

- Infrared camera

- Scanning acoustic microscope

- Roll-to-Roll (R2R) slot die coating lined

- R2R electron beam curing coating line

- R2R UV curing coating line

- R2R freeze tape casting coating line

- R2R calendering and pressing line

- Pouch cell line capability with a multi-stacked cell capacity of up to 5 Ah, X-ray diffraction equipped with operando solid-state cell

- X-ray photoelectron spectroscopy equipped with operando solid-state cell

- Focused-ion beam & scanning electron microscope equipped with operando solid-state cell; Spray coating or tape casting technologies

- Hot isostatic pressing

Flow Battery

- Corona plasma treatment

- Pilot-scale slot-die coating line

- UV curing line

- Electron beam curing line

- Hot calendaring

Crosscutting

- Data analytics, machine learning algorithms and visualization tools used for high production rate manufacturing

- In situ Raman microscopy and time resolved electroanalytical spectrometers for in-line manufacturing and device endurance testing

- Dedicated gloveboxes for sulfur, oxide, and nonaqueous device component synthesis and processing

Facilities

Crosscutting

- Battery Manufacturing Facility (BMF) https://www.ornl.gov/content/battery-manufacturing-facility

- Manufacturing Demonstration Facility (MDF) https://www.ornl.gov/facility/mdf

- Center for Nanophase Materials Science (CNMS) https://www.ornl.gov/facility/cnms

- Spallation Neutron Source (SNS) https://neutrons.ornl.gov

- Carbon Fiber Technology Facility (CFTF) https://www.ornl.gov/facility/cftf

- Oak Ridge Leadership Computing Facility (OLCF) https://www.olcf.ornl.gov

- Energy Storage and Conversion Manufacturing Group https://www.ornl.gov/group/energy-storage-and-conversaion-manufacturing

- Energy Storage Group https://www.ornl.gov/group/energy-storage

Pacific Northwest National Laboratory

Capabilities

Solid-State Battery

- Synthesis of highly conductive solid-state electrolyte (up to 200g/batch),

- Dry processing of solid electrolyte membrane and electrode,

- Pouch cell design and prototyping. Cell design for cylindrical and prismatic cells.

Flow Battery

- High throughput robotic electrolyte formulation (aqueous and non-aqueous) and characterization including both physicochemical and electrochemical property testing and database,

- Flow battery testing capability and testing database from single cell to multi-cell stack systems (up to 100kW/400kWh),

- Redox flow battery prototyping including electrolyte production, flow field CFD design, cell parts manufacture, battery assembly and testing of flow batteries (up to 10kW),

- Machine learning models for flow battery cell performance prediction (physics-informed data driven continual learning models).

Crosscutting

- Advanced scientific tools including in situ and in operando characterization tools dedicated to battery research,

- Machine learning models for molecular and electrolyte property prediction,

- Machine learning models for property extraction from scientific literature.

Equipment

Solid-State Battery

- Advanced extrusion system,

- Roll-to-roll manufacturing,

- Diagnostic tools from materials to electrode and cell level understanding (PFIB/Scanning Electron Microscope, Cryo-Transmission Electron Microscope, MicroCT, mechanical test); multi-scale modeling.

Flow Battery

- Two Big Kahuna robotic platforms (one in inert atmosphere) integrated with Electrochemical Impedance Spectroscopy, CV, high performance liquid chromatography-mass spectrometry, and other testing apparatus equipped with machine learning algorithms for autonomous testing,

- >20 flow battery testing stations (up to 100kW/400kWh) equipped with potentiostat/galvanostat and battery testers,

- Nuclear magnetic resonance, EPR, Raman, ICP, X-ray photoelectron spectroscopy, SIMS, and other advanced characterization tools.

Crosscutting

- Supercomputing cluster,

- High Performance Computing resource for machine learning.

Facilities

Solid-State Battery

- Advanced Battery Facility (pouch cell line and dry room)

Flow Battery

- Advanced flow battery lab

Crosscutting

- Environmental Molecular Sciences Laboratory

Sandia National Laboratories

Capabilities

Solid-State Battery

- Synthesis, characterization and evaluation for solid-state electrolytes including inorganic solid materials, solid polymer systems, and quasi solid state electrolytes,

- Fabrication and evaluations of materials in both insertion and conversion batteries across a range of cell sizes,

- Laboratories and capabilities dedicated for investigation of several materials targets such as ionogels, garnet, perovskites, and polymeric materials.

Flow Battery

- Synthesis and characterization of active molecular species,

- Synthesis and characterization of state-of-the-art separator membranes,

- Flow battery assembly and testing expertise for both static and flowing test configurations.

Crosscutting

- Comprehensive materials and chemicals characterization expertise (Materials Characterization – Comprehensive suite of professionally-operated tools to provide high resolution microscopy (scanning electron microscope (SEM), transmission electron microscope (TEM), Aberration Corrected-Scanning Transmission Electron Microscope (AC-STEM), cryo-TEM, laser PFIB for battery sectioning AFM, vacuum AFM/STM, electrochemical AFM, advanced optical microscopy, electrochemical scanning probe microscopy), spectroscopies, chemical analyses (mass spectrometry, microprobe, X-Ray Diffraction (XRD), energy-dispersive X-ray spectroscopy, X-Ray fluorescence, gas-chromatography). Many available in dry room environments or with inert transfer options.

- Additional mechanical characterization of bulk materials, interfaces, rheology, tribology, and nanoscale features is available. Electrolyte synthesis, and degradation studies with above spectroscopic tools including viscometry, dielectric relaxation spectroscopy and an analytical laboratory.)

- Comprehensive electrochemical characterization of materials and battery prototypes (linear and cyclic voltammetry, amperometry and potentiometry, galvanostatic intermittent titration (GITT)), transient and steady-state measurements, electrochemical impedance spectroscopy (mHz to MHz), electrochemical cycling, variable temperature measurements.)

- Destructive physical analysis: Physical disassembly of cells before and after abuse or electrochemical testing, including advanced materials characterization under inert or dry-room environments

- Computed Tomography (CT) Scanning: 3D imaging of batteries before & after testing, accommodating a wide range of sample sizes.

- Lab-scale and meso-scale battery testing,

- Battery integration expertise (e.g., with power electronics),

- Materials development capabilities supporting inorganic synthesis (bulk ceramics, molten salts, glasses, metals, and nanomaterials), organic synthesis, (small molecules, biomolecules, polymers), thin film synthesis (sputtering, sol-gel, evaporation, atomic layer deposition (ALD), pulsed layer deposition (PLD)), and composites.

- The Sierra Multiphysics software platform includes several components for solid mechanics and dynamics.

- This platform includes Adagio, the solid mechanics code; Aria the fluid mechanics code; and Arpeggio the transfer code for the Sierra components.

- Sandia’s LIM1TR (Lithium-Ion Modeling with 1-D Thermal Runaway) is an open-source code that uses the finite volume method to simulate heat transfer and chemical kinetics on a quasi 1-D domain.

- The original target application of this software is to simulate thermal runaway in systems of lithium-ion batteries, but the system may be adapted to explore a variety of principles that affect alternative battery chemistries.

- QuESt: a free, open-source, Python-based application suite for energy storage evaluation and analysis developed to bring Sandia energy storage analytics research tools to users.

- Microgrid Design Toolkit (MDT): a decision support software tool for microgrid designers in the early stages of the design process. The software employs powerful search algorithms to identify and characterize the trade space of alternative microgrid design decisions in terms of user defined objectives such as cost, performance, and reliability.

Equipment

Solid-State Battery

- Lab scale solid-state battery assembly and testing,

- Air-free or dry-room battery assembly and testing equipment,

- Hydraulic and electromechanical load frames, and a custom 4-station pneumatic pressure tester.

Flow Battery

- Flow battery components including test cells,

- Gas analysis capabilities,

- Membrane conductivity and ion-transport characterization tools,

- 3D Printing tools for custom flow field development.

Crosscutting

- Multi-channel battery testers, electrochemical potentiostats, advanced materials and characterization capabilities. (See expertise above),

- Battery calorimeters (4 standard size, two enhanced volume accelerating rate calorimeters (ARCs),

- Materials synthesis and development equipment including chemical fume hoods, air-free chemical handling (Schlenk lines and glove boxes), dry-rooms, microwave synthesis, layer-by-layer film growth, spin-coating, high temperature and controlled atmosphere furnaces (up to 1500 degrees Celsius), spark-plasma sintering furnace.

Facilities

Solid-State Battery

- Several dedicated laboratories for solid state battery (SSB) research and development (R&D) across the laboratory,

- Multiple material specific synthesis and evaluation capabilities across inert, dry room, and regular laboratory spaces.

Flow Battery

- Flow battery assembly and testing laboratory,

- Meso-Scale Aqueous Battery Lab: A lab to study why performance and degradation changes in Redox flow batteries and non-flowing aqueous batteries as they scale or as a function of different integration methods.

Crosscutting

- The largest Department of Energy (DOE)-dedicated R&D facility equipped to prototype and manufacture small lots of test batteries of various sizes, including 2032-coin cells, 18650s, D-cells, and prismatic cells (<4Ah). Maintain ~80,000 sq ft. of manufacturing and prototyping capabilities including 10,000 sq ft of dry room space; Comprehensive facilities enable full processing of electrodes and battery assemblies. 3D printing capabilities allow for flexible cell designs, novel prototypes, and agility across a wide range of battery chemistries and cell designs. Additive manufacturing facilities enable component fabrication, functional ink formulation and printing, and printing capabilities including roll-to-roll, slot-die/flexographic coating and micro-gravure printing.

- Battery Abuse Testing Laboratory (BATLaB): DOE core facility capable of destructive testing of batteries up to 800 Wh under a variety of stressing stimuli. Coupled with advanced characterization capabilities, this facility provides invaluable opportunity to explore the fundamental mechanisms behind battery degradation and failure.

- Battery Test Facility: 500 independent channels available for battery testing of any chemistry and format, from coin cells to kilowatt amp hour (kAh) modules. Capabilities include 150 mA to 2000 A current range capability, 70+ thermal chambers, with –72°C to 95°C temperature capabilities, two static-controlled assembly benches, welding capabilities, including resistance, pinch, and a 90 W spot welder are available.

- Burn Site Test Facility: Capable of destructive testing of batteries and systems up to 25 kWh

- Energy Storage Test Pad: In conjunction with the Energy Storage Analysis Laboratory (ESAL), provides long-term testing and validation for electrical energy storage systems. Sandia also provides pre-certification, pre-installation, and verification of energy storage systems. The goal of the ESTP is to develop advanced energy storage technologies that will increase reliability, performance, and competitiveness of electricity generation and transmission.

- Battery Energy Storage Test Laboratory: Committed to developing and evaluating new battery module and power converter architecture to improve energy storage performance and lifetime

- Distributed Energy Technologies Laboratory (DETL): a multipurpose research facility designed to integrate emerging energy technologies into new and existing electricity infrastructure to accommodate the nation’s increasing demand for clean, secure and reliable energy.

- ESCAL (Battery integration test lab): System integration and controls lab is a test bed to integrate different battery chemistries in simulated grid operations. Can be used to develop battery management and energy management systems to operate a battery. Has been used to understand how different battery chemistries interact with each other and why certain configurations are optimal.

- 120Vac Single Phase / 208Vac three-phase 37kVAac Ametek power amplifier sink/source for simulating electrical loads or grids

- OPAL-RT real time simulator with power-hardware-in-the-loop control

- A&D Data Acquisition and High-speed control with multiple communication protocols

- Outback grid/off-grid inverter rated at 24Vdc input and 5kWac output

- APEX lab (Power electronics for energy storage lab): Power electronics development lab, rapidly produces prototypes of power electronics systems that connect BESS to each other and the grid. Work includes developing various architectures to combine cells in various module formats to understand why different configurations improve or reduce overall system performance.

- Center for Integrated Nanotechnology (CINT): a Department of Energy/Office of Science Nanoscale Science Research Center operating as a national user facility devoted to establishing the scientific principles that govern the design, performance, and integration of nanoscale materials. CINT features laboratories for low-vibration for sensitive characterization, chemical and biological synthesis, a clean room for device integration, interaction areas and conference rooms, visitor office space, and high-speed communications. The distinguishing characteristic of CINT is its emphasis on exploring the path from scientific discovery to the integration of nanostructures into the micro and macro worlds.

- Multiple dedicated materials chemistry laboratories,

- Module cycling Lab: A lab to study how batteries (e.g., lithium-ion (Li-ion) and solid state Li batteries, presently) operate in assembled modules over long term cycling protocols and simulated real work cycling operations. Battery testers can gather module and cell level data simultaneously while applying any type of simple or complex waveform desired to understand why performance changes under any type of power electronics or controls developed by ESCAL and Apex and any type of duty cycling.

- Thermal Test Complex (TTC): designed to serve as an international resource for validation of fire physics models as well as the nuclear weapons complex hardware qualification facility for fires. This $40-million facility, completed in the winter of 2005, offers one-of-a-kind capabilities and positions SNL as a technical leader in the fire science community. Experimental fire research, validated modeling tools, and phenomenological model development capabilities form the basis of an integrated capability to solve high-consequence problems in fire prevention, fire consequence analysis, and fire mitigation (firefighting).

- CONET Lab: The Control and Optimization of Networked Energy Technologies (CONET) Laboratory conducts research, development, and testing of coordinating networked and distributed systems for several different operational objectives. In order to achieve its objectives, CONET focuses efforts in five basic areas, all of which are cross-cut by cybersecurity: Coordinated Communications, Controls & Distributed Systems, Optimal Dispatch, Projection and Reconfiguration, Prognostics & Decision Support.

Savannah River National Laboratory

Equipment

Crosscutting

- Multichannel potentiostat/frequency analyzer,

- Bipotentiostats, high current potentiostats,

- Electrochemical surface finishing – electroplating and electropolishing,

- Spray deposition and tape casting for porous electrode fabricate,

- Automatic ultrasonic spray coater,

- Speed mixers, homogenizers, a variety of mills for slurry preparation,

- Furnaces for post preparation electrode processing,

- Characterization equipment such as laser confocal microscope, surface area analyzers, and electron microscopes.

SLAC National Accelerator Laboratory

Capabilities

Solid-State Battery

- Pouch-cell fabrication and electrode processing,

- Synthesis and processing of lithium based solid electrolytes and cathodes,

- Operando and ex-situ X-ray synchrotron diagnostics of large format batteries and electrodes,

- Scanning probe and cryo-electron microscopy of battery materials and interphases.

Flow Battery

- Accelerated testing of flow cells,

- Failure mode analysis using X-ray synchrotron imaging and spectroscopy.

Crosscutting

- Electrochemical impedance spectroscopy and high precision coulometry,

- Technoeconomic Analysis (TEA) of battery material manufacturing and processing and long duration energy storage chemistries,

- Battery Informatics: The SLAC Battery Informatics Lab undertakes large format cell testing and analytics. Data ingestion, storage and analysis/machine learning are performed automatically via cloud-based computing.

Equipment

Solid-State Battery

- Large co-precipitation reactor for cathode materials scale-up,

- High temperature hot-press and sintering,

- 600 battery cell cyclers, 11 environmental chambers, electrochemical impedance spectroscopy and high precision coulometry,

- Three source dual e-beam thermal evaporation chamber for the synthesis of alloy anodes equipped with quartz-crystal microbalance,

- Custom designed high temperature and high pressure reactor from Altamira Instruments.

Crosscutting

- 2” wide web for roll-to-roll or sheet to sheet printing of thin films compatible with the beamlines. Print heads ranging from slot-die to blade coating.

- Single layer laser powder bed fusion (LPBF) system for characterization of metal additive manufacturing at the beamlines,

- Agilent Gas Chromatograph/Mass Spectrometer (GCMS) for on-line product analysis. Product analysis is performed using the GCMS Flame Ionization Detector (FID),

- Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) setup designed for the operando and in-situ characterization of powdered materials and electro-catalysts.

Facilities

Solid-State Battery

- https://www-ssrl.slac.stanford.edu/,

- https://s2c2.slac.stanford.edu/,

- https://lcls.slac.stanford.edu/.

Flow Battery

- https://www-ssrl.slac.stanford.edu/,

- https://s2c2.slac.stanford.edu/,

- https://lcls.slac.stanford.edu/.

Crosscutting

*Details on national lab capabilities were provided by the National Laboratories. For more information on capabilities, facilities, or equipment, please reach out to the National Laboratory point of contact.