Supercritical carbon dioxide (sCO2) power cycles have the potential to reduce the cost of concentrating solar power (CSP) by far more efficiently converting high-temperature solar heat into electricity.

The Solar Energy Technologies Office pursues dramatic cost reductions in technologies to make solar electricity available to all Americans. Next-generation CSP system designs use sCO2 turbine power cycles to more efficiently convert solar thermal energy to electricity and reduce the cost of CSP technology.

Because sCO2 power cycles work best at very high temperatures and under intense pressure, a CSP system needs receivers and heat exchangers that can withstand these conditions. Heat exchangers contribute up to 60%−70% of the total cost of a CSP sCO2 turbine system, so low-cost, highly efficient exchangers are necessary to help make CSP cost-competitive.

Applications for Concentrating Solar Power

- Direct Solar to sCO2 power tower: The power cycle working fluid also serves as the power tower heat transfer fluid.

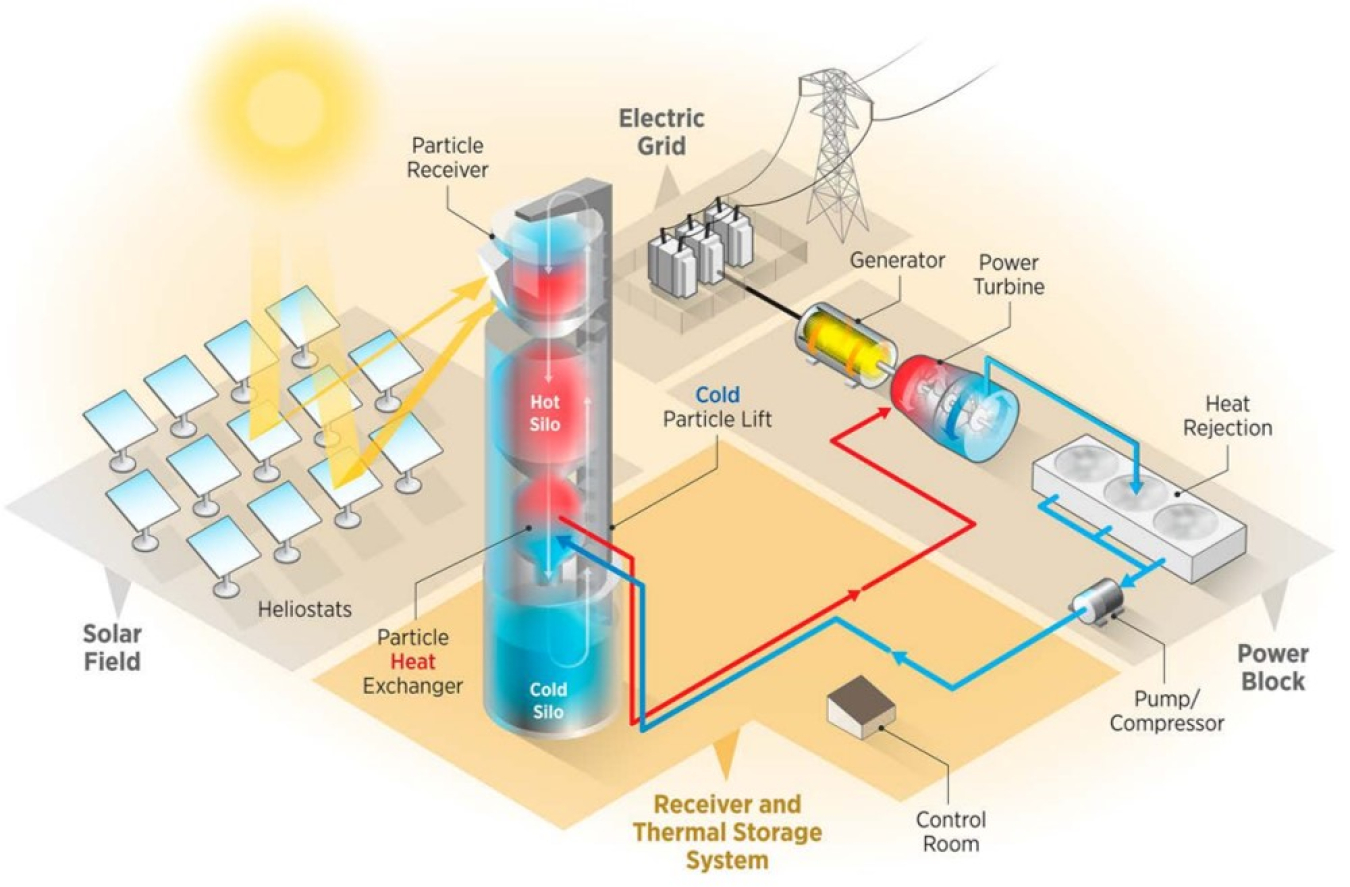

- Indirect sCO2 power tower: A high-temperature stable material is heated with sunlight, then a heat exchanger transfers the thermal energy into the power cycle. (see schematic below)

- Potential to increase maximum temperature of the heat transfer media to <1,000oC

- Well-suited for scalability to 10-100 MWe power tower systems

Benefits Uniquely Valuable to CSP

- Reduces water consumption compared to current Rankine process

- Makes smaller, more dispatchable power plants cost viable

- Reduces capital costs by increasing the efficiency of converting sunlight into energy.

Research Focus Areas (also see References)

- Lifetime performance of sCO2-compatible materials

- Turbomachinery design, manufacturing, and testing sCO2 regenerators

- Integration of CSP heat transfer media with sCO2 cycle

- CSP subsystems compatible with >720°C sCO2 cycle inlet temperature