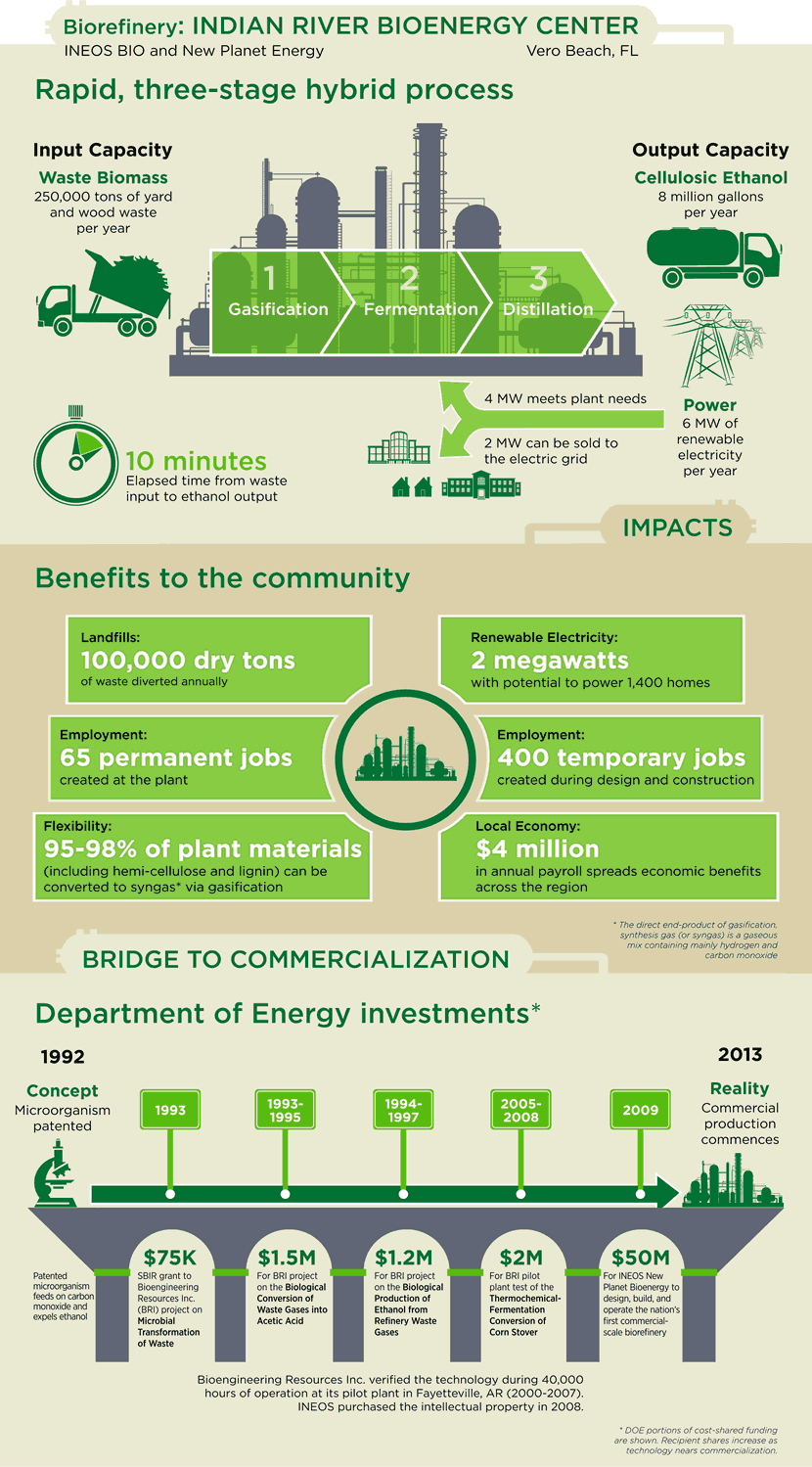

Waste Biomass

Photo via iStock by Getty Images.

Photo via iStock by Getty Images.

The feedstock-flexible processing technology at Indian River BioEnergy Center takes advantage of the abundant local supply of agricultural and yard waste.

Municipal trucks delivering these wastes pay a tipping fee to the biorefinery, while local residents can drop off yard waste at no charge. Diverting this organic material from the nearby landfill helps to extend the useful life of that facility.

Biomass of diverse shape, size, and density is mixed together and dried with waste heat from the biorefinery prior to processing.

Gasification

Photo via iStock by Getty Images.

Photo via iStock by Getty Images.

Dried biomass enters the lower part of the gasifier, where it is exposed to high temperatures to form a pyrolysis gas intermediate.

After passing into the upper part of the gasifier, the pyrolysis gas is exposed to more heat, this time with added oxygen, so it cracks into syngas (a mixture of carbon monoxide, hydrogen, and carbon dioxide).

Gasification continues in a reducing environment at a slightly negative pressure to suppress the formation of dioxins or furans and prevent emissions.

The syngas is then cleaned, cooled via heat exchangers, scrubbed, quenched, and compressed prior to entering the fermenter. High-pressure steam created with the recovered heat is used to generate electricity.

Fermentation

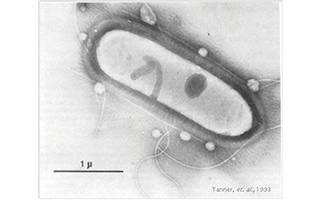

Photo courtesy of Dr. Ralph Tanner.

Photo courtesy of Dr. Ralph Tanner.

When the clean, cooled syngas enters the fermenter, it is exposed to a proprietary bacteria at ambient temperature and low pressure. This naturally occurring bacteria tolerates variations in syngas composition and common catalyst poisons, converting the syngas into ethanol with great efficiency.

This highly selective, high-yield process requires minutes instead of the day or more needed for other existing commercial processes. High yields are based on the technology’s unique ability to convert lignin, pentose, and other carbon-containing fractions of the biomass.

While added nutrients promote automatic regeneration of the biocatalyst, it dies upon exposure to oxygen—eliminating any unintended application. Unreacted syngas is cleaned and combusted to generate additional power.

Distillation

Photo via iStock by Getty Images.

Photo via iStock by Getty Images.

Distillation is a mature technology that uses differences in boiling points to separate and purify the liquid products.

The Indian River BioEnergy Center uses the waste heat from gasification to continuously distill the liquid extracted from the fermenter. A molecular sieve performs further purification, yielding an anhydrous ethanol that meets road fuel quality standards —ready for blending and use.