Flip through to see the many types of hydropower facilities and technologies that sustain communities across the United States.

Water Power Technologies Office

August 19, 2024Hydropower comes in many shapes and sizes. It can be generated from irrigation canals, rivers, and reservoirs—and new technologies can enhance hydropower at large by helping to protect fish, increase energy generation, and reduce its overall footprint.

Hydropower accounts for nearly 27% of total U.S. utility-scale renewable electricity generation and about 6% of total U.S. utility-scale electricity generation. This resource plays a key role in the electric grid today and as it evolves to incorporate more variable renewable energy sources like wind energy and solar power. Hydropower will help ensure the grid remains reliable and stable, providing electricity to homes and businesses when they need it.

In honor of National Hydropower Day on August 24, the U.S. Department of Energy’s Water Power Technologies Office (WPTO) is showcasing hydropower’s diversity. Flip through our hydropower lookbook to see the many types of hydropower facilities and technologies that sustain communities across the United States.

Pumped storage hydropower (PSH) facilities use water and gravity to create and store renewable energy. PSH relies on two reservoirs of water, one at a higher elevation than the other. During periods of high energy production, excess energy can be used to pump water up into the higher reservoir. At times of high demand, PSH facilities can release water from that higher reservoir into the lower pool. When the water flows downhill, it spins a turbine, running a generator and producing clean power. There are currently 43 pumped storage hydropower plants located across the United States—with clusters of facilities in California, Arizona, Colorado, Georgia, and the Carolinas.

Instead of a large dam and reservoir, run-of-river hydropower systems use the natural flow of water to generate power—flowing water is diverted through a channel or penstock to drive a turbine. For a run-of-river system to be possible, the river must flow steadily (from rainfall or a melting snowpack) and have a tilt (from a small dam or the natural landscape).

Conduit hydropower involves retrofitting existing water-carrying structures (like canals, pipelines, and aqueducts) with equipment that generates electricity. There are opportunities to more than double conduit hydropower in the United States, with the largest resource potential in the western states of California, Colorado, Washington, Nebraska, and Oregon.

Technology innovation can enable the sustainable growth of additional hydropower capacity and generation. For example, of the more than 90,000 dams in the United States, less than 3% produce power. Adding power-generating infrastructure to these existing dams offers opportunities to expand hydropower capacity.

Impoundment is the conventional and most common type of hydroelectric power plant, using dams to contain water in a reservoir. The contained water is released as needed, flowing through a turbine to generate electricity. This was an empty link: There are There are more than 2,250 conventional hydropower plants in the United States.

Fish passage and protection technologies provide a way for fish to move safely through or around dams. These technologies also provide river connectivity by enabling fish movement and migrations, reducing environmental impacts and restoring fish population levels. Acoustic sensors, ladders, and bypass channels are some examples of fish passage and protection technologies.

Hydropower operators must maintain components like sensors, penstocks, and machinery parts, as well as the surrounding landscape. Maintaining a hydropower system and its infrastructure not only preserves the health and longevity of a plant, but also helps maximize electricity generation.

Testing infrastructure will be key to hydropower’s future, especially for modernizing existing facilities, deploying PSH, and developing small hydropower. That’s why WPTO launched the Hydropower Testing Network—the network will connect hydropower technology developers to testing capability providers to help advance technologies toward commercialization. Technology developers will be able to apply for testing services through the network during Phase 2, which is expected to open in fall 2024!

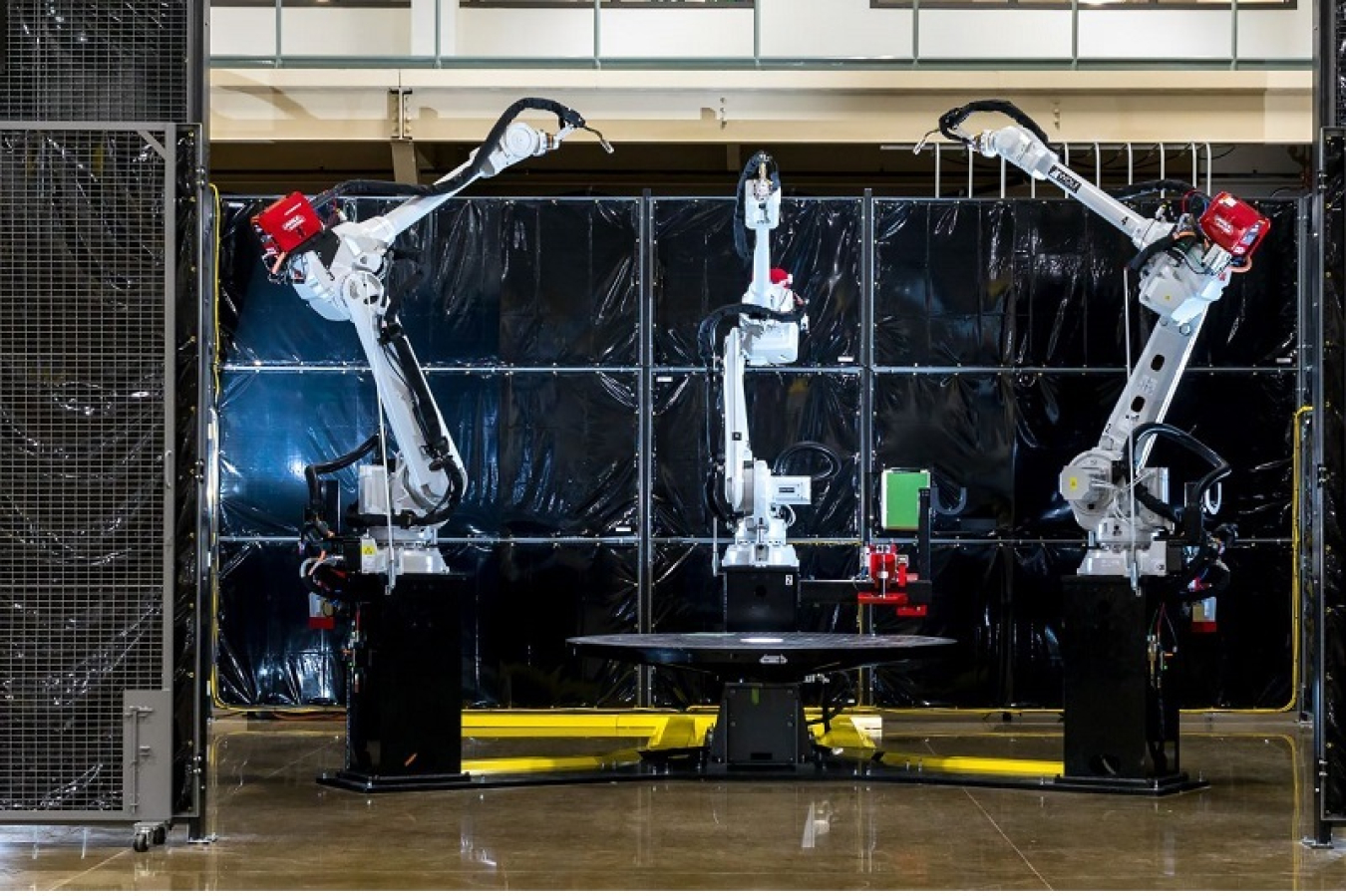

Advanced manufacturing and materials have tremendous potential to boost U.S. manufacturing competitiveness, as well as alleviate maintenance, environmental, and operational challenges at both hydropower and manufacturing facilities. For example, additive manufacturing solutions (also known as 3D printing) can reduce manufacturing waste while enabling modern turbine designs. That’s why WPTO developed the Advanced Manufacturing and Materials for Hydropower Strategy, which outlines goals to guide WPTO’s efforts related to hydropower and advanced manufacturing.

Stay up to date with the latest hydropower funding opportunities, events, and news by subscribing to the monthly Water Wire and the bimonthly Hydro Headlines newsletters.