The technology developed can be used to produce sustainable aviation fuel.

February 20, 2024This technology was developed in the BETO-funded CO2RUe consortium mission and can be used to produce sustainable aviation fuel.

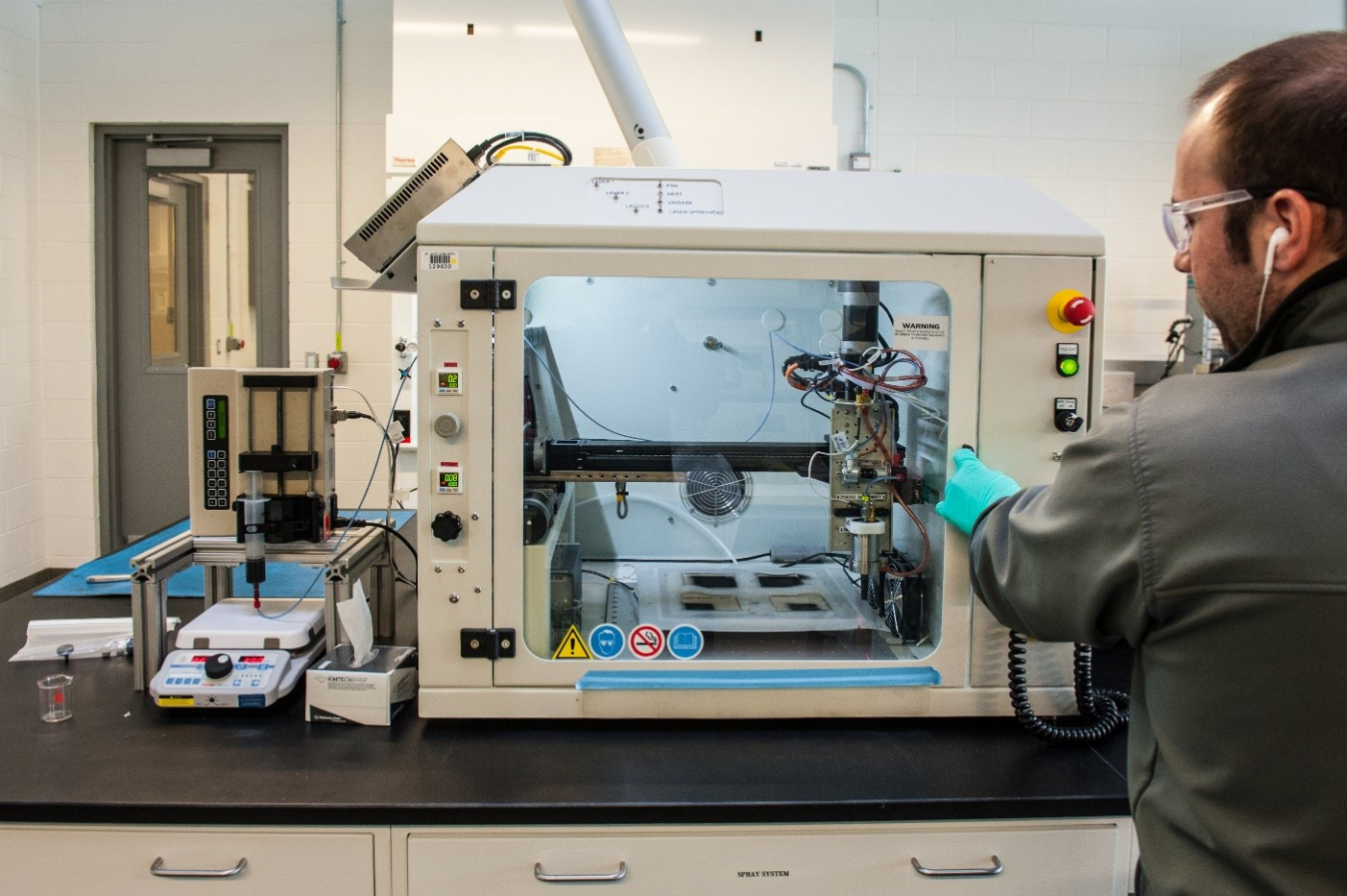

National Renewable Energy Laboratory (NREL) research scientist Dr. K.C. Neyerlin applies catalyst layers to a cell through a spray process that delivers a more even distribution of material, improving performance of the cell. Research like this helped inform the current study to generate formic acid from CO2. Photo by Dennis Schroeder/NREL

Identifying routes to efficiently convert carbon dioxide (CO2) to an intermediate chemical which can be further upgraded to fuels or commercially valuable chemicals has been challenging. New research from U.S. Department of Energy (DOE) national laboratories discovered a promising pathway to produce formic acid from CO2 with high energy efficiency and durability using renewable electricity. The study titled, A Scalable Membrane Electrode Assembly Architecture for Efficient Electrochemical Conversion of CO2 to Formic Acid, was published in Nature Communications.

Formic acid is a potential intermediate chemical which has a wide range of applications, especially as a feedstock for the chemical or biomanufacturing industries. Formic acid has also been identified as an input for biological upgrading into sustainable aviation fuel (SAF).

The research team led by Dr. K.C. Neyerlin at the National Renewable Energy Laboratory, with team members from Argonne National Laboratory and Oak Ridge National Laboratory, investigated several membrane electrode assembly (MEA) configurations in an electrolyzer cell to compare electrochemical reduction of CO2 to formic acid.

When an electrical potential is applied to an electrolyzer cell, CO2 electrolysis results in the reduction of CO2 into chemical intermediates such as formic acid or molecules such as ethylene. The MEA in the electrolyzer cell typically includes an ionically conductive membrane (cation or anion exchange) sandwiched between two electrodes consisting of electrocatalysts and ionically conducting polymers.

Leveraging the team’s experience in fuel cells and hydrogen electrolysis technology, they modified an MEA electrolyzer cell with a novel perforated cation exchange membrane to achieve stable, high selectivity formic acid production.

Through techno-economic analysis the team confirmed that this process is economically viable if the technology can be scaled to industrial applications and the cost of hydrogen meets intermediate DOE targets ($2/kg by 2026).

In addition, the team achieved these results with commercially available catalysts and polymer membrane materials, while producing an MEA design that leverages the scalability of today’s fuel cell and hydrogen electrolysis stacks. The results of this study may enable a more rapid transition to scale and commercialization using renewable electricity and hydrogen to convert CO2 into fuels and chemicals.

Mission Alignment with BETO’s CO2RUe Consortium

Funded by DOE’s Bioenergy Technologies Office (BETO), this technology aligns with the BETO-funded CO2 Reduction and Upgrading for e-Fuels Consortium (CO2RUe). The multi-national laboratory consortium, along with industry guidance, has been tasked with developing a portfolio of technologies that use renewable electricity, catalysts, and microorganisms to upgrade CO2 into more useful and energy-dense molecules.

Learn more about CO2RUE and the CO2 conversion technologies it develops and derisks.