An NREL study explores opportunities for increasing wind turbine hub height and the conditions and locations where these towers have the most impact.

Wind Energy Technologies Office

May 20, 2019Research assesses tall turbine tower energy production, cost, and viability

Back in the day, parents would record a child’s growth with fresh pencil marks on a door frame. As wind technology grows in scale and productivity, researchers continue to look for ways to boost the energy captured while driving down costs. A new National Renewable Energy Laboratory (NREL) study, Increasing Wind Turbine Tower Heights: Opportunities and Challenges, explores opportunities for increasing the height of wind turbine hubs—where the turbine drivetrain and rotors attach—and the conditions and locations where these taller towers would have the most impact.

Innovations from DOE, other research institutions, and industry have allowed wind turbine hub heights and sizes of rotors (blades) to grow and increase energy production. Since the 1980s, new pencil notches have been added to the door frame for wind turbine growth, as average U.S. commercial wind turbines’ hub height has quadrupled (from 20 to 88 m) and rotor diameter has expanded fivefold (from 20 to 116 m). Average wind turbine nameplate capacity—or the amount of power a turbine can output under ideal conditions—has also increased leaps and bounds, from less than 100 kilowatts per turbine to approximately 2.4 MW per turbine in nameplate capacity in 2018.

Taller towers make it possible to cost-effectively tap the stronger wind resources that exist at higher levels, beyond the reach of today’s typical turbines and above interference from trees, buildings, and landscape or topographical features. Taller wind turbines also provide the additional clearance needed for longer blades that increase energy capture per turbine.

“Over the past four decades, wind turbine scaling has been critical to wind power cost reduction. Looking ahead, scaling continues to offer potential cost savings, but new innovations are needed to enable scaling while effectively managing capital expenditures and the logistics of moving equipment to the plant site,” said NREL Group Manager and Researcher Eric Lantz.

Recent NREL analysis assessed how increased hub heights could impact key indicators of wind energy viability across the nation. Research looked at factors of wind speed, capacity factor, and LCOE, as well as incremental costs that could be incurred for increases in turbine hub height. The team also used Wind Plant Integrated Systems Design and Engineering Model (WISDEM) to examine how innovation in materials, design, transportation, and installation might overcome limits to tower base diameter and hub height. (See the separate news item on WISDEM for more details on this innovative modeling tool.)

“These innovations could span an array of materials, controls, manufacturing, and transport solutions,” says Lantz. “For this effort, we sought to characterize and weigh the interplay of these factors with the amount of additional energy that might be extracted in order to inform the design and innovation of tall tower technologies that could deliver tangible new benefits.”

Higher hub heights make it possible to cost-effectively tap wind resources beyond the reach of today’s turbines. Photo by Dennis Schroeder, NREL 27196

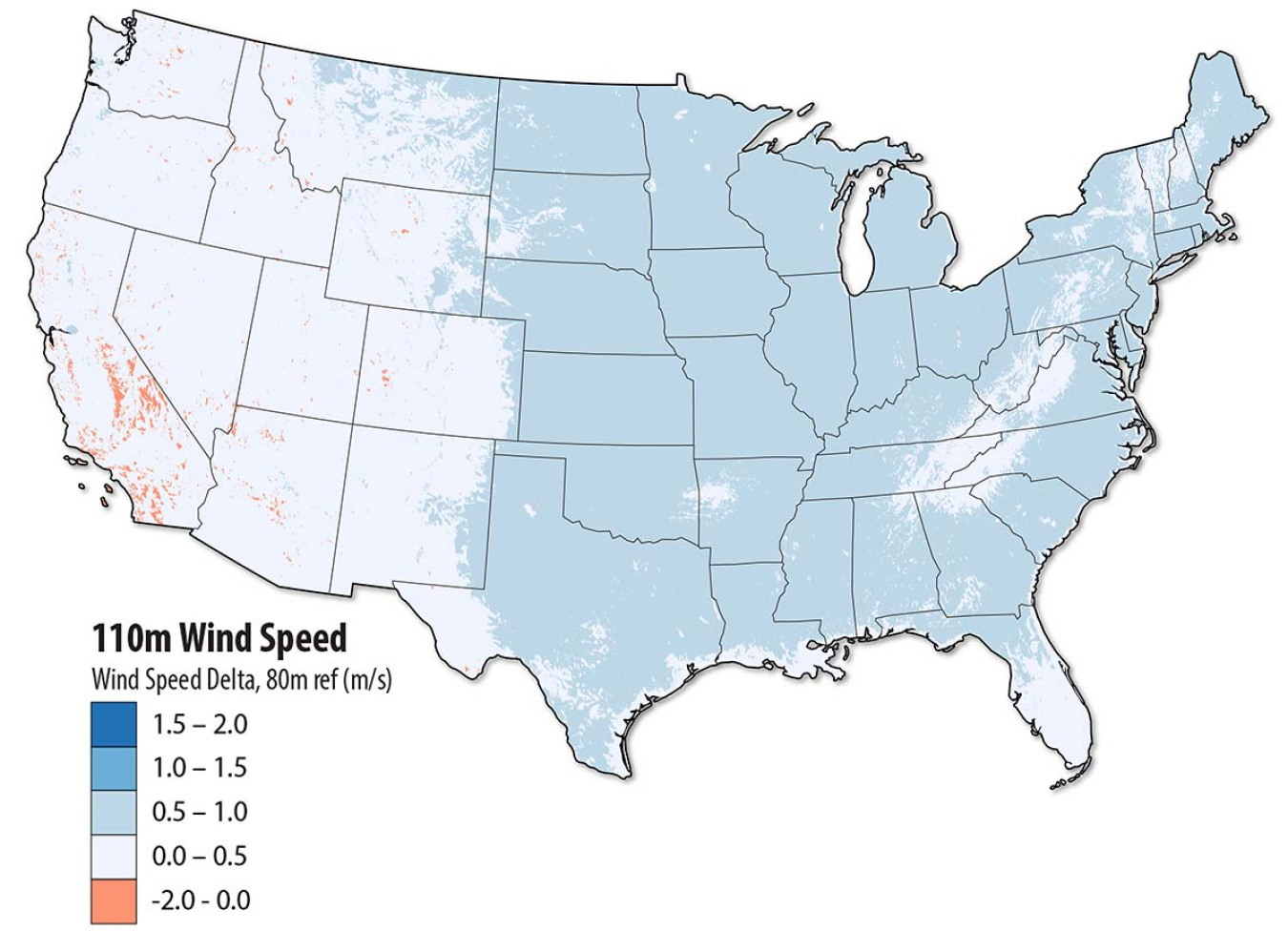

Difference in mean annual wind speed 110 m above ground level minus 80 m. Figure by NREL, based on the Wind Integration National Dataset Toolkit

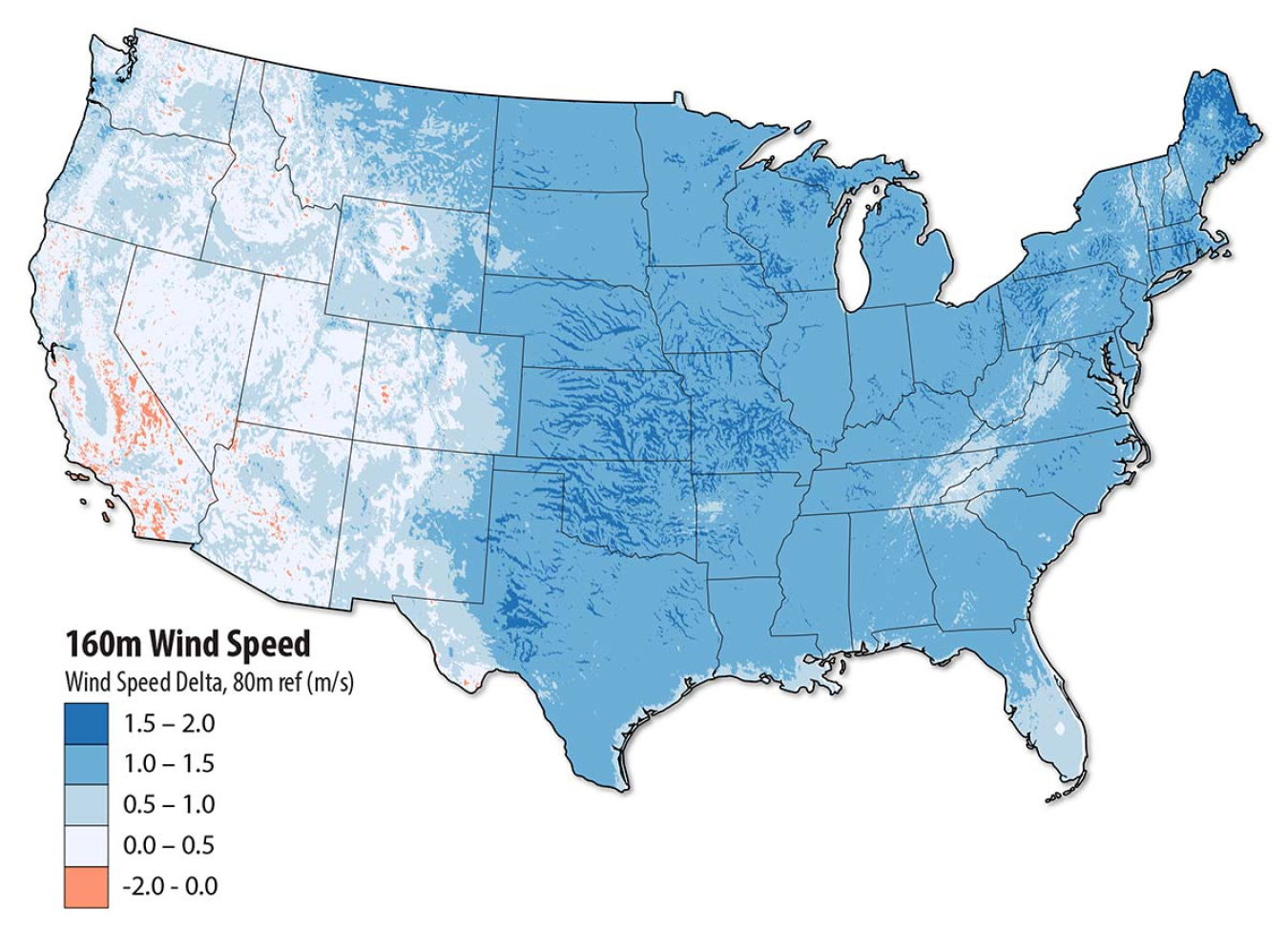

Difference in mean annual wind speed 160 m above ground level minus 80 m. Figure by NREL, based on the Wind Integration National Dataset Toolkit

The analysis indicated that there are many areas that could warrant the pursuit of technology enabling higher hub heights. Growing hub heights to 110 m for the three modeled conceptual turbines in the 3-MW to 5-MW size class led to capacity factor increases of about 10 percentage points (e.g., from 35% to 45%) in many locations, with continued capacity factor improvement with hub heights of 140 m.

Hub heights of 110 to 140 m could also offer LCOE advantages relative to today’s common turbines, particularly in locations where wind shear is relatively strong, including much of the eastern United States. Another notable aspect of tall tower technology is the impact that system innovations can have on opportunities to increase hub height. As one example of more system-focused innovations, advanced controls have greatly increased the viability of tubular steel towers for economically achieving higher hub heights in recent years.

Around the world, the push continues for higher and higher hub heights. In Germany, to maximize the value of that country’s lower quality wind resources and relatively smaller area available for wind development, turbine hub heights are on average approximately 50% higher than those found in the United States. Ongoing research at NREL and other national laboratories will help guide future research to reduce the cost of wind energy and increase the contribution of wind to the electrical grid.