2014 Nobel Prize recipient Shuji Nakamura focused on SSL’s cutting edge.

Workshop Presentations and Materials

About 250 researchers, manufacturers, industry insiders, and observers gathered in Long Beach, California, January 31–February 2, 2017, to participate in DOE's 14th annual Solid-State Lighting R&D Workshop. DOE SSL Program Manager James Brodrick emphasized that despite all the impressive gains SSL has made to date, there's still a huge amount of untapped potential. He noted some of the biggest remaining challenges—such as droop and the green gap for LEDs, light extraction and stable blue emitters for OLEDs—and observed that if these are solved and DOE goals are met, the payoff will be $50 billion in annual energy savings by the year 2035. Brodrick played two short videos on the remaining technological hurdles—one on LEDs, the other on OLEDs—and remarked on the new opportunities that are enabled by SSL, such as color-tuning, connected lighting, human-centric lighting, and horticultural lighting. "Light is not just for lighting" anymore, he said.

Innovations in SSL

The University of California at Santa Barbara's Shuji Nakamura, who won the 2014 Nobel Prize in physics for inventing the energy-efficient blue LED, set the tone of the workshop by focusing on SSL's cutting edge, discussing such innovations as tunnel-junction blue/green LEDs, violet LEDs, microLEDs, patterned sapphire substrates, high-power semipolar laser diodes (LDs), and Li-fi using LEDs and LDs. He explained the rationale behind each of these innovations. For example, Nakamura noted that Li-fi is 250 times faster than superfast broadband Wi-Fi, can be 10 times cheaper, is more secure because it can't penetrate walls, and has almost no limits on capacity whereas Wi-Fi is already close to full capacity.

Bruce Bugbee of Utah State University discussed using LED lighting in indoor farms.

Turning Photons into Food

Bruce Bugbee of Utah State University discussed the science as well as the practical economics of using LED lighting in indoor farms, explaining that selectively tuning the spectrum can not only increase crop yield but can also change such characteristics as nutritional content, disease resistance, appearance, and taste. He noted that LEDs have helped scientists tremendously in better understanding the role of light in the growth of plants.

Bugbee said even if LEDs were100% efficient in producing photons, indoor farming wouldn't be economically feasible for fundamental staple crops such as wheat; whereas it's already feasible for high-water-content crops such as tomatoes and lettuce. He said it's "almost certain" that we could optimize the spectrum for certain stages of plant growth.

Action Spectrum and Beyond

A panel moderated by DOE SSL team member Jeff Tsao of Sandia National Laboratories explored the use of engineered light to accommodate various applications and their associated action spectra. Wouter Soer of Lumileds noted that in the past, spectral engineering was confined to CCT, color fidelity, and spectral efficacy, but that's changing because improved red phosphors remove the tradeoffs between efficacy and CCT/CRI, and new applications require an extended set of metrics to measure spectra. He said spectral engineering in the future will also involve chromaticity, color gamut, individual color saturation, and nonvisual stimulation (i.e., melanopic content). Focusing on retail, outdoor, and circadian lighting, Soer noted that whereas chromaticity is important in virtually all applications, color fidelity is often not the most important metric, and which metrics are key depends on the application. He concluded that we need more application-based metrics for spectral design, Po-Chieh Hung of Konica Minolta discussed optimizing the spectral power distributions (SPDs) of white light to any action spectrum. He reviewed the advantages and disadvantages of six parameters for optimizing SPDs: maximum luminous efficacy of radiation (LER), maximum color gamut, maximum impact on the eye's intrinsically photosensitive retinal ganglion cells (ipRGCs, which play a key role in the body's physical response to light), minimum impact on the ipRGCs, minimum damage to museum artifacts, and elimination of blue light (i.e., all light below 500 nm) to avoid exposure to photoresist. Hung cautioned that although spectral optimization is possible for virtually any application, the "spiky" spectra that result may distort color perception both visually and photographically.

A panel of experts considered the use of engineered light to accommodate different applications.

Scott Rosenfeld of the Smithsonian American Art Museum looked at minimizing light-caused damage to art objects. He observed that because the light that illuminates objects in a museum also fades those objects, "we should make every photon count." Rosenfeld explained that the less light exposure, the less damage, and said he'd be thrilled if tuning the spectrum were a panacea that allowed significantly higher illuminances without causing additional damage. He said action spectrum is useful for predicting the fading of specific objects but requires spectroscopy to determine what pigments and dyes are present, and is not commonly used; whereas using a standard delay format (SDF) of 400-780 nm is most useful for reducing damage to durable colors.

Susanne Seitinger of Philips Lighting talked about the role connected lighting can play in smart cities.

Tessa Pocock of Rensselaer Polytechnic Institute (RPI) considered the action spectrum from a plant's point of view. Noting that there are 12 different types of photoreceptors in plants, she explained that the entire spectrum activates those photoreceptors, driving the process of photosynthesis. Chloroplast, Pocock pointed out, serves as both a sensor and as a signal. Light exposure, she said, plays a role in determining not only flowering, but also photoperiodism (the plant's response to seasonal changes in day length), circadian rhythm, height, leaf expansion, branching, stomatal opening, pigments, immunity, and defense. Pocock described related studies on plant sensing that have been conducted at RPI's Center for Lighting Enabled Systems & Applications (LESA),

Smart Cities: Urban Soundscapes and the Lighting Grid

Susanne Seitinger of Philips Lighting described how connected lighting can play a key role in creating smart cities by leveraging the existing infrastructure to provide valuable information on the environment, traffic, noise, and the network itself. Noting that almost no other type of city infrastructure is as visible as lighting, which makes it ideal for connectivity, she focused on the City of Los Angeles, which has converted more than 170,000 of its streetlights to LED so far. Seitinger described a small pilot study in a multi-use section of Los Angeles, where about 30 LED luminaires were connected and equipped with sensors and controls. She noted that sound is a great proxy for traffic and that, among other things, initial data demonstrates drastic difference in noise levels between arteries and neighborhood streets.

The Luminaire Industry Beyond LED Replacement

Martin Siegel of Zumtobel explored the challenges luminaire manufacturers face because of SSL.

Martin Siegel of Zumtobel discussed the new set of challenges faced by luminaire manufacturers in the wake of the advent of SSL. He predicted that the disruption caused by LEDs will continue to change the landscape of the lighting industry, with much of that disruption coming not from the LED technology itself, but from it breaking down barriers to other industries. Siegel forecast that as LEDs technology continues to saturate the industry, two trends will continue to strengthen: cost pressure will drive prices for volume products, with added functionality counteracting this. "We're caught between a rock and a hard place," he said. "We need to reduce cost, but at the same time we need to add functionality." Siegel said that in either scenario, R&D spending by luminaire manufacturers will have to adapt significantly.

Thinking Ahead for Domestic SSL Manufacturing

A panel moderated by DOE SSL team member Morgan Pattison of SSLS, Inc., explored developments in technology, applications, and manufacturing approaches that will drive SSL manufacturing decisions going forward. Mark Benguerel of Finelite, which does all of its manufacturing in California, noted that fluorescent lighting comprised 95% of Finelite's sales in 2011, whereas 95% of the company's sales is now SSL. He explained that the transition from fluorescent to SSL has enabled Finelite to focus on producing "tailored lighting," which is defined by the customer's needs and architecture rather than by predetermined configurations and thus is free of traditional constraints on length, wattage, and color. Benguerel related how adjusting the manufacturing process to the concept of tailored lighting – which has involved giving every luminaire a unique ID number that's central to the whole process – has shortened lead times, thus adding value and strengthening competitive advantage.

Mark Hand of Acuity, which manufactures both here and abroad, explained that manufacturing overseas works when there are a limited number of SKUs, and when the products are small enough in size to minimize shipping costs, but pointed out that the long lead times that result are unsuitable for many applications and expose the manufacturer to being stuck with merchandise that's been rendered obsolete by sudden market shifts. Manufacturing in the U.S., Hand noted, not only reduces lead times and shipping costs, but also lends itself to complex designs and innovation. He cited lean manufacturing as the key to reducing labor costs here in the U.S. For example, where Acuity once had 28 people producing 280 units per hour in 5,000 square feet of space, that production has increased to 300 units per hour using 16 people in 2,200 square feet of space.

Panelists Mark Benguerel, Mark Hand, Eric Haugaard, and Warren Weeks considered factors that will drive domestic SSL manufacturing.

Eric Haugaard of Cree cited the importance of optimizing manufacturing space utilization, using flexible manufacturing technologies that support rapid innovation, and keeping inventory in least-common-denominator form. Haugaard noted that the Cree facility where he works has more than doubled its number of employees over the past five years, and called human-resource management the biggest challenge for any kind of manufacturer. He said Cree is using robots in its manufacturing, but those robots integrate well with humans – an essential characteristic. Looking toward the future, Haugaard predicted that SSL products will feature new form factors, be smaller and weigh less, offer more options for housing materials, and offer many different SKUs created from a small bill of materials.

Warren Weeks of Hubbell Lighting noted that his company manufactures its "stock-and-flow" products – such as LED downlights – overseas, while its more-complex products that entail high numbers of SKUs are made here in the U.S. He observed that although Hubbell's business model hasn't changed much since the advent of SSL, the company itself has undergone drastic changes, such as having to retool its factories and retrain its workforce. The technical skillsets of that workforce, Weeks said, have shifted from mechanical to electromechanical, electronics, and software. He noted that although the number of Hubbell's employees has increased along with revenue growth, "right-sizing" has resulted in a reduction in the number of manufacturing facilities.

LED Lighting Installations

An optional evening bus tour at the end of Day 1 provided an inside view of the City of Los Angeles' streetlight evolution. Los Angeles has the nation's second-largest municipal street lighting system, has converted more than 170,000 streetlights to LED technology, and is at the forefront of outdoor connected lighting. At the executive offices of the Los Angeles Bureau of Street Lighting, attendees visited the newly relocated Historic Streetlight Museum and heard Bureau Director Ed Ebrahimian present an overview of the city's LED street lighting conversion program and Smart City initiative. Then, after a drive-by view of different phases of the LED streetlight conversion, the tour visited a Smart City pilot site to hear Philips Lighting's Susanne Seitinger describe and demonstrate some of the sensor-based capabilities of connected street lighting.

Attendees on the evening tour experienced street lighting’s past, present, and future in Los Angeles.

Mission of the Workshop

Morgan Pattison wrapped up the first day by providing an overview of the purpose of the DOE SSL R&D workshops, setting the stage for the in-depth discussions in the coming track sessions. He outlined the DOE SSL R&D planning process and encouraged attendees to provide their feedback, which he noted will help DOE update its SSL R&D Plan and overall R&D efforts. "It's your chance to guide where we go with the program," Pattison said. "If you want to know where you're going, you have to know where you're at."

Brodrick kicked off Day 2 with an overview of DOE's SSL R&D program direction and areas of focus. He observed that the nearly 270 cost-shared projects funded by DOE to date have yielded more than 270 patents and 220 different products that have a huge industry footprint. Brodrick noted that the total value of current DOE-funded projects is $42.6 million, with an average cost share of 28%, and that SSL projects have received an additional $44 million in funding since 2000 from DOE's Small Business Innovation Research program. He pointed out that achieving DOE's SSL efficacy targets will not only bring enormous energy savings, but also far-reaching scientific and technological advances, better LED products with improved lighting quality, lower first costs for LED products, and stronger positioning of domestic manufacturing.

Lighting and Display Technology Synergy

Panelists Barry Young, Juanita Kurtin, and Charles Li focused on the impact of OLEDs, quantum dots, and microLEDs.

A panel moderated by DOE SSL team member Norman Bardsley of Bardsley Consulting explored the impact of OLEDs, quantum dots, and microLEDs and their role in the design and manufacturing of lighting products. Bardsley noted that the use of LEDs as display backlights drove advances in LED manufacturing. Panelist Barry Young of the OLED Association considered what OLED lighting can learn from OLED displays, which have grown tremendously since 2008. He predicted that the capacity to make them will double between 2016 and 2017 and then double again between 2018 and 2021. That increase, Young said, will be driven primarily by smartphones, most of which will use OLEDs by 2021. He explained that as the yields of OLEDs started to improve, OLEDs started to become as viable as LCDs for display, and today they're even cheaper than LCDs. Young noted that unlike OLED lighting, OLED displays need a polarizer, which is one way the cost of OLED lighting can be reduced. But he observed that there are other opportunities to reduce cost as well, such as reducing the dopant component.

Juanita Kurtin of Pacific Light Technologies talked about enabling efficiency and color with on-chip quantum dots (QDs). She explained that there are also two other ways of integrating QDs into LED applications: on-edge and on-surface. Kurtin said that QDs provide improved color quality, have a much larger color gamut than traditional phosphors and OLEDs, and can provide up to 25% efficiency gains for SSL – plus they don't require large fabrication facilities. She stated that QD-level encapsulation technology reduces manufacturing cost and complexity, that QDs in powder form are the only true drop-in replacement for phosphors, and that no glass or film protection is needed.

Charles Li of PlayNitride discussed microLEDs, a new type of display that he said has many advantages over LCDs and OLEDs. Li noted that microLEDs can be as small as 2.5 microns and can have a very high resolution – up to 2,000 dpi for full color and 5,000 dpi for monochromatic. The goal of microLEDs, he explained, is for every pixel of a display to be an independent LED. As a result, the display can be very thin – less than 60 microns. Li said microLEDs can go up to 15,000 nits in brightness, have a very fast on-off response, consume only 10% of the power consumed by LCDs, and have a large color gamut (1.17 area ratio). While microLED displays still face some hurdles that need to be overcome, including high cost, he said, "this is a very promising technology; we believe it will happen soon."

Integrating Lighting into Buildings

A panel moderated by DOE SSL team member Monica Hansen of LED Lighting Advisors reviewed different concepts for integrating lighting into buildings, and the value propositions they represent. Scott Hershman of LF Illumination focused on SSL's unique qualities – small size, digital nature, extended color range, directionality, low heat generation, and low voltage – and how it can be optimized within the architecture to create a better visual and subjective human experience. He noted that smaller luminaires means that lighting solutions can be more discrete, minimizing the impact on the architecture, and that being able to avoid framing opens up new possibilities. But Hershman pointed out that LEDs are an order of magnitude brighter than conventional sources, so glare has to be taken into account. Because little heat is produced, he said, seamless lines of light can be created, and other services, such as sprinklers, can be integrated into the fixture.

Brad Koerner of Philips was among the panelists discussing various ways of integrating lighting into buildings.

Brad Koerner of Philips observed that the advent of SSL plays right into the revolution taking place in architectural construction, and that with SSL there's no reason to be constrained to conventional fixtures. He cited areas that will play leading roles as SSL proliferates, including connected lighting and embedded lighting. Koerner noted that architects want to treat lighting like a material. Using specific projects to illustrate, he described several paradigm-changing developments – including the creation of luminous carpets, luminous textiles, and luminous patterns. Koerner predicted that in about five years, the high-volume production of "light sheets" – whether LED, OLED, or a combination – will be a viable reality. "Think about the millions of square miles of architectural surfaces we can target," he said.

Evan Petridis of Enlighted focused on data gathering. He pointed out that traditional building information and control systems are data-poor, operating mostly at a binary off/on level, with rudimentary data granularity, whereas what's needed is fine-grain data, with time-synchronized sensors. Petridis noted that lighting is an ideal place to install such sensors, because it covers the whole building, providing position and power, and in return, the sensors give every light intelligence to optimize its behavior. He observed that real estate costs two orders of magnitude more than energy in an office environment, so the payback for optimizing it is much larger, and sensors embedded in the lighting can collect accurate data from the entire building. "Every time an LED luminaire goes in without a sensor is a lost opportunity," Petridis said.

Wen-Lin Tsao of Cisco discussed a converged IP network for building and IT systems her company has developed, which uses power over Ethernet (PoE). She noted that buildings are getting increasingly complex, and that most building systems today are running in silos and are not sharing information, which can create security challenges. With a networked system, the lights communicate with the management system, with the wall switches, and among themselves, for example. Lighting, Tsao said, is a key first step to transform a building into an automated digital network, so that users are able to adapt their environment to personal preferences, sensors can help to optimize workspace utilization, and costs can be reduced by substantial energy savings.

Leveraging DOE SSL R&D

Joel Chaddock of National Energy Technology Laboratory noted that the DOE SSL R&D Plan, which is updated annually in collaboration with industry partners, guides DOE SSL program priorities and informs not only DOE-sponsored R&D, but also research agendas in academia and industry. He went over the DOE SSL program elements (Core Technology Research, Product Development, and Manufacturing R&D), as well as current DOE SSL Funding Opportunity status. Chaddock reviewed other DOE funding mechanisms relevant to SSL, such as Small Business Innovative Research (SBIR) grants and those involving Energy Frontier Research Centers and the Advanced Manufacturing Office, and noted the different ways attendees can get involved, including annual R&D funding opportunities, DOE's OLED testing collaboration, and various DOE-facilitated working groups.

Marc Ledbetter of Pacific Northwest National Laboratory focused on DOE's SSL technology application R&D, which consists of field and laboratory evaluations, technical support for new industry standards development, and technology competitions. He discussed seven DOE projects in the works: a study on the potential impacts of LED road lighting on sky glow, which looks at the combined effects of spectrum, flux, and uplight; a GATEWAY study on the use of various types of OLED luminaires in the offices of an accounting firm; a GATEWAY study on the use of color-tunable luminaires in a classroom setting; the Next Generation LuminairesTM design competition's switch in focus to whole systems, as reflected in its new name, Next Generation Lighting Systems; the latest report on the effects of a high-temperature environment on LED luminaires; and a long-term study of downlights for cycling effects.

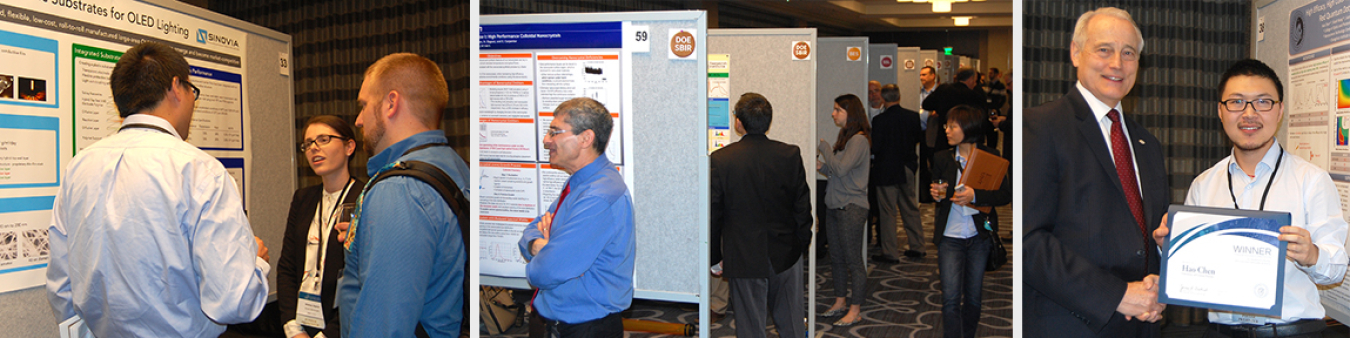

The evening poster session featured 60 SSL R&D projects—including four winners of a university student competition—as well as numerous demonstrations of products and prototypes.

Poster Session

The evening of Day 2, researchers representing 60 projects presented their work at a poster session and reception sponsored by the Next Generation Lighting Industry Alliance, providing attendees with additional opportunities for discussion, information exchange, and potential partnering. The projects were funded not only by the DOE SSL program, but also through DOE under the Small Business Innovation Research (SBIR) grants, the Advanced Research Projects Agency–Energy (ARPA–E), and the Office of Basic Energy Sciences (BES), as well as through DOE joint programs with the National Institute of Standards and Technology. Four posters representing the SSL student competition included winners from the University of California–Santa Barbara, University of Central Florida, Rensselaer Polytechnic Institute, and Boston University. In addition, a dozen R&D participants demonstrated products and prototypes, ranging from OLED panels and fixtures to a dashboard data tool for monitoring LED streetlights.

A Market Perspective from Asia

Mark McClear of Seoul Semiconductor offered a global perspective on LED lighting.

Mark McClear of Seoul Semiconductor offered a global perspective on the LED market for lighting, LED manufacturing, the evolution of LED technology, and the use of mid- and high-power LEDs in lighting. He noted many changes in the lighting market, but also many constants. McClear stated that although the cost reductions have been "breathtaking," the low-hanging fruit may soon be gone. He noted some uncertainty in the supply chain, due to the fact that consolidation in China is occurring, several of the major LED suppliers are making major structural changes, and the distribution channel is maturing. McClear predicted that innovation will continue to be the real engine to enable new cost points and applications, and said the companies (and shareholders) who pay for that innovation should be repaid for their investment.

LED Track Sessions

A panel moderated by Morgan Pattison covered opportunities and challenges for developing luminaires that demonstrate value beyond traditional lighting expectations. Ram Ramabhadran of GE Global discussed power electronics as an enabler for modular luminaires. He noted that the driver is a fraction of the cost of the whole LED lighting system, so the question becomes how to enable more modular, cost-effective luminaires. Ramabhadran considered the manufacturing aspect of drivers, with a focus on integration into luminaires to bring down the total cost. He cited moving to a lower-part-count design as being key, but observed that in order to get the cost down enough, magnetics has to be addressed. The driver, Ramabhadran said, is a component that could be significantly reduced in part count, integrated with the light engine, automated, and reduced in cost.

Dorene Maniccia of Philips Lighting talked about tunable patient-room lighting.

Alireza Safaee of OSRAM talked about the integration of drivers and luminaires for indoor applications. He said if you want the flexibility to integrate the driver into the luminaire, you have to reduce the total height of the driver and thus reduce its components without increasing the part count or sacrificing robustness or reliability. The goal, Safaee stated, is to try to print the magnetic conductors on the PCB using higher frequencies (27 MHz). He considered the merits of Nordic Power Converters, higher power density, using a stacked structure where each of the converters processes part of the energy, and having high power density at low cost and fewer components. In conclusion, Safaee said the driver must have a low profile and high power density.

Chad Stalker of Acuity Brands gave an OEM perspective on luminaire integration, drivers, and controls. He focused on three current areas for improvement: form factor, common fixture infrastructure, and dynamic lighting solutions. Stalker said that form factors should be smaller, more flexible, and offer programmability. With regard to the common fixture infrastructure, he raised the question of whether the "Internet of the fixture" should be standardized, and suggested supporting this so that components can be interchanged. In considering dynamic lighting, Stalker related that the lighting needs to be moved every time, and the efficiency needs to be moved to the correct level as well.

Dorene Maniccia of Philips Lighting discussed tunable patient-room lighting, noting that soon such systems will have tunable hues that can modulate and change with the time of day. She described a system Philips created for patient rooms that gives the user a great deal of control, tunes the spectrum of light, provides a CRI of 85 for exams, and offers four points of CCT (from 2700 K to 5000 K). Maniccia noted that as such systems move from a single-channel platform to more channels, they lose efficacy. She said the lighting has to be put into a system with controls and human interaction before its energy use can be accurately judged. Maniccia stated that more application guidance is needed, and the industry can use more help deciding on metrics.

A panel moderated by Jeff Tsao explored new manufacturing methods on the horizon for luminaires, quantum dots, power supply components, and optics. Sridhar Nimma of Eaton Lighting discussed new manufacturing methods for connected lighting. Observing that more than 70% of the luminaire's cost is in the housing, he noted that the manufacturing processes used today are subtractive processes, which involve a lot of wasted shear. Nimma called additive manufacturing, which doesn't waste anything, the future. He said that future will involve printing the housing, the electronics, the sensors, the optics, the LEDs, and then the interconnect and assemblies. Nimma also said metal needs to be replaced by plastic to reduce the weight of products. He said the past has been module-based, but the future needs integrated solutions, which can be achieved through additive manufacturing.

Jonathan Owen of Columbia University spoke about graded-alloy quantum dots (QDs). He said QDs can produce a very narrow red luminescence, which can make for very efficient LEDs with very high CRI. Owen noted that QDs were originally placed on the die, but performance issues caused early adoption to be in thin films away from the chip. He said the performance of QDs has been steadily improving as newer structures are obtained, and graded-alloy QDs – where the composition rather than the size of the dot is what gives off the color – are now the preferred type. Owen noted that the reagents used to synthesize the dots haven't changed in 15 years, and said his project aims to improve them to gain better control over the QD characteristics and boost performance in a more systematic way.

Attendees took advantage of breaks in the proceedings to chat extensively with the speakers.

Seth Coe-Sullivan of Luminit discussed new manufacturing methods for light shaping, focusing on the use of holographic optical elements in light-shaping diffusers (LSDs) as secondary lenses for LEDs. He observed that light shaping with designed refractive optics is already a critical part of the LED ecosystem, and explained that LSDs are manufactured roll-to-roll, roll-to-sheet, and by injection molding. Coe-Sullivan predicted that for cost and efficiency reasons, light shaping will get pushed closer to the chip. He said that new manufacturing methods – such as computer-generated holography and the use of curved injection molding to make light-shaping diffusers – can help bring light shaping to LED chips and packages.

Juan Rivas-Davila of Stanford University discussed the work his group has done with 3D-printed power converters. He explained that power converters typically use PCBs with inductors and capacitors that tend to dominate the size and weight of the converter, but have slow improvement in size and performance and are typically just "dumb connectors." Rivas-Davila said that by increasing the switching frequency of the power converter, you can reduce the size and weight of it. He noted that semiconductors have allowed for great advances in recent years and also allow for higher frequency operation, but have hit a wall. Rivas-Davila said it's possible to 3D-print the air-core, which doesn't require any magnetic material, and the inductors and capacitors could potentially be printed on the PCB.

A panel moderated by Monica Hansen explored R&D in various down-converter materials and primary optics designs for improved efficiency. Oleg Shchekin of Lumileds discussed LED technology considerations for high-luminance sources. He noted that there are two dominant LED architectures, but their light is not fully useful and could be better. Mid-power LEDs, Shchekin said, are high-extraction die designed to run at low power, while high-power LEDs have high extraction with a flip-chip architecture. The limitation of mid-power sources, he said, is the etendue and brightness of the source. Shchekin concluded that high-luminance LEDs can enable significant value-add from system form factor, weight, and cost reductions, but that developing efficient high-luminance LEDs requires improvement in epitaxy droop, die design for high power densities, die and package technologies for high photon extraction, and low droop phosphors for warm-white color and high Ra.

Sir Colin Humphreys of the University of Cambridge tackled carrier localism, efficiency droop, cubic GaN, and the green gap.

Jonathan Melman of Lumenari talked about the use of red phosphors for LED lighting. He said that large efficacy gains can be realized with continued red phosphor development, explaining that the gains are primarily driven by a narrow emission spectrum, with the elimination of longer-wavelength red emissions improving the luminaire efficiency rating. Melman emphasized that emitters shouldn't be discarded simply because they have low efficiency, adding that it's important to keep looking at narrow emitters in combination with other phosphors for the efficiency boosts at the phosphor level, and that moderate quantum efficiency could still be good enough in the short term when coupled with narrow emission. Melman also noted that parasitic excitation has the potential for small efficacy improvement.

Jennifer Hollingsworth of Los Alamos National Laboratory talked about the quantum yield, stability, and scale-up of quantum dot downconverters. Noting the need for a replacement phosphor for the red band, she described the ongoing development of giant quantum dots (gQDs). Hollingsworth explained that whereas conventional QDs blink, which limits their quantum efficacy, these gQDs are nonblinking and also nonbleaching. What's more, she said, they suppress Auger recombination, energy-transfer funneling, and non-self-absorption. Hollingsworth noted that the nanoscale structures can be applied across different material systems, with similar results, and that the quantum yield is now as high as 90%.

Ralph Tuttle of Cree discussed design considerations with LED package primary optics. He focused on LED package designs that optimize light extraction, considered the benefits of a flat lens versus a spherical one, and discussed the applications of flat-lens LEDs in designs. In comparing a flat versus a domed lens, Tuttle noted that light extraction in LEDs is governed by Snell's Law, and that without an encapsulant, any light at an angle greater that 23.6 degrees would be reflected into the chip. He explained that for streetlights, low-refractive-index silicone is preferred, in order to minimize color shift. Tuttle related that while light can be redirected with a lens, the flat LED is much better at directional LED beam applications, and said candela per Watt may be a more appropriate metric for efficacy than lm/W.

Members of a panel on light-emitting materials, physics, and devices interact with audience members during a break.

A panel moderated by Jeff Tsao explored new research results in light-emitting materials, physics, and devices, including those that intersect two ongoing key challenges: efficiency droop and the green gap. Sir Colin Humphreys of the University of Cambridge in the U.K. spoke about carrier localism, efficiency droop, cubic gallium nitride (GaN), and the green gap. He noted that at the onset of droop, there's a simultaneous change in the S-shape temperature dependence of the photoluminescence, due to the saturation of localized states, and that excess carriers injected are free to diffuse to defects and may also enable the onset of Auger recombination – suggesting that the saturation of localized states initiates droop by an Auger mechanism and possibly also by a defect mechanism. Humphreys said cubic GaN exhibits strong multiple-quantum-well emission up to 540 nm and is compatible with commercial LED processing, representing the first steps towards demonstrating a viable cubic GaN LED technology.

James Raring of Soraa Laser discussed the use of laser diode plus phosphor (LDP) for highly directional solid-state lighting. He said that LDPs solve the luminance challenge of LEDs, with the laser diode changing the device's physics, and the stimulated emission mode allowing for higher drive. But Raring noted that although LDPs today have only half the efficiency of LEDs, we need to look at the delivered lumens, which show that for longer throw distances, LDPs get much better lm/W. He reviewed the benefits of LDPs (e.g., glare-free dynamic illumination, larger range, smaller size) as well as their challenges (e.g., wall-plug efficacy needs improving), predicting that LDP technology will evolve and mature to gain widespread adoption.

Jim Speck of the University of California at Santa Barbara focused on high-luminous-efficacy green LEDs with an aluminum gallium nitride (AlGaN) cap layer. He pointed out that red and blue diodes are much more efficient than green ones because they have no Stokes loss and much smaller source size. Speck reviewed the advantages of using tunnel junctions (TJs) with green LEDs (e.g., cheaper packaging, ~90% light extraction, no problem with current spreading) but noted that one of the fundamental problems with TJs and MOCVD is that when you've buried p-type GaN and activated it and try to grow n-type GaN on top of it in MOCVD, it's difficult to get the hydrogen out in the normal direction, so you have to use sidewall diffusion, which is a big challenge.

Tetsuya Takeuchi of Meijo University in Japan talked about creating nitride-based tunnel junctions with MOCVD. He explained that cascaded LEDs using TJs don't have to increase the current but can increase the voltage to input large amounts of power to minimize efficiency droop, and that we need a low-temperature-grown, p-side structure to suppress the thermal damages in the activation for green LEDs, in order to surpass the green gap. Takeuchi said that because it can be grown at low temperatures, InGaN could be the answer, adding that perhaps p-GaN can be grown at low temperatures. He described the process by which his team obtained low-resistive MOCVD-grown nitride-based tunnel junctions with high-In-content GaInN grown by MOCVD, and said nitride-based TJs are ready to be used in various optoelectronic devices.

On Day 3, LED attendees split up into small groups to discuss a variety of topics considered key to furthering SSL technology advances, with each table focusing on a specific R&D topic to allow for in-depth consideration of related issues.

OLED Track Sessions

A panel moderated by Norman Bardsley identified remaining challenges regarding the fabrication of OLED lighting panels, with the focus on encapsulation, electrical connections, the incorporation of internal extraction layers, and control of the active organic materials. Michael Boroson of OLEDWorks predicted that in 10 years, all lighting will be solid-state, with OLEDs favored over LEDs in applications that are close to the user as well as those that value unique form factors. He expressed the hope of there being dedicated OLED drivers by 2018, which will enable luminaire efficacies of 80 lm/W. Boroson said a high-capacity production machine is needed to get costs down, but sales volume needs to increase in order to enable investment in such equipment. The way to grow demand, he stated, is by offering more choices, including a variety of shapes and sizes, flexible lighting, and color-tunability. Boroson identified roll-to-roll (R2R) production as a key to bringing costs down, and cited DOE assistance as critical to the success of OLED lighting.

Herman Schoo of the Holst Centre in the Netherlands discussed the open innovation programs being carried out on the high-tech campus of that organization, which used to be part of Philips Research. He cited several examples, including the creation of an R2R moisture barrier film tool and process, which can coat low-cost foils at desired rates and deliver a barrier suitable for OLED encapsulation; and the R2R solution-processing of active layers and electrodes for OLEDs and organic photovoltaics (OPVs). Schoo focused on one of three separate pilot lines currently in production: Pi Scale, which involves the creation of an independent, open-access service for the fabrication of flexible OLEDs, to bridge the gap between R&D and mass production, and to help establish a sustainable industry around flexible

OLEDs in Europe

Chris Brown of Kateeva talked about manufacturing equipment and process solutions for flexible and large-size OLEDs, focusing on inkjet printing. He reviewed the advantages of inkjet printing for OLEDs, including the fact that it can be used for thin-film encapsulation (TFE) and red-green-blue (RGB) pixel printing of OLED displays and can be easily adapted for other applications, such as lighting. Brown noted that inkjet printing is the accepted approach for depositing the TFE organic layer in mass production, explaining that one key aspect of the approach is that the ink and process can accommodate defects and minimize their impact on the device. He said OLED displays are just the beginning for Kateeva's inkjet printing tool, which has attracted interest from OLED lighting and other applications.

David Rowe of 3M discussed barrier film manufacturing for OLED lighting. He explained that barrier films are necessary to protect OLEDs, and that R2R processing is the key to bringing the cost down but has a number of issues, such as cleanliness, moisture management, and process control. Rowe noted that barrier-film technology – which includes two layers of polymer with an oxide in between, on a flexible substrate – has been commercialized in other markets, such as displays and solar cells. He described the optical calcium test, which he said can be used to determine if moisture is coming in axially and/or laterally, and related that 3M is partnering with various companies making OLEDs.

A panel moderated by DOE SSL team member Lisa Pattison of SSLS, Inc., explored OLED product design and integration, focusing on the total system, including panel, driver, and luminaire. Mike Lu of Acuity Brands talked about the development of an OLED luminaire with individually addressable panels, focusing on the driver side of the luminaire. He described how Acuity has addressed the challenges facing OLED drivers, including standardizing into two classes of drivers (high wattage and lower wattage) and using EldoLED Hybrid Hydra drivers. Lu noted that increasing luminaire functionality has meant increasing the number of independently controlled groups of light sources, and that carrying this trend to its logical conclusion will result in every light source being addressable. He described a DOE-funded project developing an OLED luminaire with panel-integrated drivers and advanced controls, and stated that while OLED panel performance needs to improve, the driver is not the impediment.

Jeff Spindler of OLEDWorks and Larry Sadwick of InnoSys focused on OLED light engines. Spindler reviewed the components of OLED panel integration, including the substrate, optical foil on the emitting side, heat pad, metal back plate, wires and connectors, and light engine. Noting that an OLED light engine is only as good as the panel, he said near-term performance goals include excellent color quality (CRI > 90, R9> 50); high efficacy (60-80 lm/W); a variety of CCTs and colors as well as shapes and sizes; good reliability; and simple integration with connectors, drivers, and luminaires. Ultimate goals, Spindler said, include flexible, tunable, low-cost panels with an efficacy of at least 100 lm/W. He noted that they're getting close, and that prices have fallen below $200/klm.

Sadwick related that InnoSys is working with OLEDWorks to develop an OLED light engine, and that many questions have arisen – such as what happens with a faulty panel, and whether the driver needs to be flat if the panel is. In reviewing the reasons to make power supplies specifically for OLEDs, he noted that OLEDs have their own considerations when it comes to being driven and controlled – e.g., they're a panel rather than a point source, and they lend themselves to a wide variety of form factors. Sadwick observed that although power supplies for OLEDs could be force-fit to work with existing LED drivers, it's best to think outside the box instead. He called for more DOE funding, as well as for collaboration, standardization where necessary, and a focus on the strengths of OLEDs in complementing LEDs.

Alireza Safaee of OSRAM discussed the past, present, and future of his company's development of OLEDs. He observed that in the past, the biggest barriers to OLEDs for general illumination have been cost, followed by efficiency and lifetime. At present, Safaee said, OLEDs are an interesting proposition for use in automobiles, where cost is less of an issue and cars are sold based on appearance; and he expects autos to be the first volume application for OLEDs. The challenge, Safaee noted, is that environmental requirements are more stringent for automotive applications, where the OLEDs are exposed to high temperature and humidity as well as to sunlight. To create widespread adoption, he said, the cost needs to come down.

Jacky Qiu of OTI Lumionics considered remaining OLED luminaire design challenges, which he predicted will take a few years to overcome. One challenge he mentioned was that interconnects are different between panel suppliers, which limits design potential. In addition, Qiu noted, mounting OLED panels into luminaires is challenging. What's more, he said, there are multiple challenges involving drivers, which are all over the spectrum in terms of driving voltage, with no available off-the-shelf solutions. Qiu cited a need for testing standards for OLED lighting, as well as a lack of panel manufacturers. While the long-term goal is superior performance, he said the short-term focus should be on brand differentiation for what people can use right now, to get more people excited about OLEDs so that they look past the high cost.

A panel moderated by Lisa Pattison looked at OLED light-extraction efficiency and optical utilization, exploring novel materials and approaches and preliminary experiments. Steve Forrest of the University of Michigan discussed challenges in achieving low-cost, spectrally broad OLED outcoupling. Noting that 80% of the light is trapped in the OLED, whereas the goal is 80% efficiency, he said a good solution needs to be inexpensive and independent of both the viewing angle and the OLED structure. Forrest related that light output can be doubled using readily available approaches that extract light trapped in the substrate. For further improvements, waveguided modules in the organic and anode layers need to be addressed. This can be done using a low-index grid adjacent to these layers. Rather than positioning the grid between the anode and organics, where it can interfere with the OLED device structure, Forrest's group is now exploring a sub-anode grid approach, lowering the position of the grid underneath the indium tin oxide (ITO) so that it's outside of the OLED active region. A sub-anode grid, he said, can outcouple all waveguide modes.

Greg Cooper of Pixelligent discussed OLED light extraction. He noted that light extraction has important benefits beyond efficiency, such as less heat, lower cost, longer lifetime, and more-uniform brightness. Cooper said that overall device performance needs to be optimized, as light extraction impacts many aspects of device performance, and he pointed out that different extraction schemes could be used together. To compare light extraction, Cooper stated, one should use external quantum efficiency (EQE) and lm/W compared to an optimized control device with external extraction layer and on the blackbody curve. Beam shaping, he said, is a functionality that can be added by novel light-extraction solutions.

Sebastian Reineke of Technische Universität Dresden in Germany talked about actively controlling the beam shape of OLEDs. He noted that the beam shape can be controlled not only to a specific setting, but to enable its tuning. The device, Reineke said, can produce a changing distribution of light as a function of time through electrical, rather than mechanical, controls. Color tuning, he explained, can similarly be achieved using the same tandem architecture, with one blue and one yellow OLED. Reineke noted that the approach can be easily combined with external optics by attaching a half-sphere or prism. An important factor, he added, is how large the light source is, compared to the distance from the observer.

A panel moderated by Norman Bardsley considered advances in organic materials and electroluminescent quantum dots. Mark Thompson of the University of Southern California focused on advances in organic materials for white OLEDs. He noted that efficiency and operational lifetime of OLEDs is limited by the blue component, and considered the degradation routes of blue emitters. Thompson said that to increase lifetime, bimolecular collisions and processes should be decreased; however, reducing exciton and polaron concentrations increases voltage, resulting in decreased efficacy. One option for preventing bimolecular decay, he stated, is to spread the recombination zone through dopant/host grading, which can increase lifetime by 10x. To improve on this, excited state "managers" can be included in the emissive layer to allow hot polarons a favorable pathway to relax before they undergo dissociative reactions (degradation) in the device. In summary, Thompson said lifetime can be extended with the use of stable emitters, hosts, blockers, and transporters, as well as managers to help protect hosts and emitters, and new device structure ideas to maximize external efficiency.

Jian Li of Arizona State University discussed OLED emissive materials beyond phosphorescence. At present, he said, thermally activated delayed fluorescence (TADF) green OLEDs have an EQE of 20% with an L95 lifetime of 2500 hours, while "hyperfluorescent" yellow OLEDs have an EQE of 13-14% with an L95 lifetime of 1060 hours. TADF blue OLEDs, Li explained, have an EQE of 20%, but lifetime is limited. Because blue requires very high triplet energy, there are few choices of stable donor and accepter materials. Li also discussed metal assisted delayed fluorescence (MADF) OLEDs, which he said can achieve stability and efficient emission because of the lower energy of the triplet state. Li concluded that stable blue emitters are key; that choices should include phosphorescent, TADF, and MADF; and that recent progress on QD-LEDs is promising.

Chris Giebink of Penn State University talked about multiscale electrical inhomogeneity in OLEDs. He noted that OLED lifetime depends strongly on current density, which, as it's increased, adds stress to small subgroups of molecules and accelerates bimolecular degradation reactions. The question arises as to how much nanoscale inhomogeneity might impact performance and lifetime, and whether there's anything that can be done about it. Giebink observed that current filaments form, initiating at interfaces, in OLED devices due to nanoscale energetic disorder. Such inhomogeneities ultimately result in a reduction by a factor of two in device lifetime. At the macroscale, the concern is shorts, which lead to heating and irreversible damage, decreasing panel yield. The goal is to be able to identify incipient shorts early and understand their physical origin and growth, so that failure can be predicted and mitigation strategies can be implemented in mapping inhomogeneities. Bright spots, Giebink noted, don't change much; whereas hot spots grow or extinguish over time. Further research is needed to establish a clear link between hot spots and shorts and to identify ways to arrest hot-spot growth.

Creating Value from Human Physiological Responses to Light

f.lux founder Michael Herf served on the final panel, which focused on human physiological responses to light.

A panel moderated by Morgan Pattison explored how our current understanding of human physiological responses to light can be applied, and what research is necessary to develop further applications. Windy Boyd of the National Institute of Environmental Health Sciences reviewed the initial conclusions of a 2016 workshop on the topic. She noted that the unintended health consequences of exposure to light at night (LAN) remain unclear. Boyd said LAN may have a broad public-health impact due to the pervasive exposure, particularly of nightshift workers, and potential to increase the risk of common diseases. She reported that multiple characteristics of electric light are related to circadian disruption, including level, spectrum, distribution, timing, duration, and photic history. In addition, light exposure during the day influences nighttime light sensitivity. Boyd also noted that shiftwork involves not only exposure to light, but also the activities enabled by light.

Jamie Zeitzer of Stanford University noted that light has a lot of other functions besides just image formation. He focused mainly on two of them: light's effect on the hypothalamus, which controls alertness and autonomic functions; and light's effect on the suprachiasmatic nucleus, which affects circadian entrainment. Zeitzer explained that any light that's visible has the potential to impact circadian rhythm, although blue light has more of an effect. He described some experiments in which circadian timing was adjusted by exposing the sleeping subject to flashing lights, which he said could be three times as effective in that regard as continuous light. Zeitzer said three hours is the maximum the human biological clock can be adjusted at a time, and noted that daytime light exposure modifies evening light responses.

Michael Herf discussed f.lux, a software program he created that's used by more than 10 million people to adjust the CCT of their computer screens in support of their circadian rhythms and biology, and how he's worked to model the effects on sleep and health of the screens and light people are exposed to. He explained that f.lux removes 80-90% of the alerting light at night and achieves more than half of its effects by changing illuminance. Herf noted that although the popular press has embraced the "alerting" effects of light and cautioned against blue light before bed, "blue" is not a dose. What's more, he said, the timing of the light dosage is important for circadian rhythm and differs between "early birds" and "night owls," as well as by age – with children more sensitive and seniors much less so.

Smith Johnston III, a NASA flight surgeon, discussed the role of lighting in managing fatigue with the astronauts under his care. He explained that sleep is a real problem in spaceflight because of a lack of cues as to the time of day, and that insomnia increases stress, which in turn increases the incidence of disease. Johnston noted that the astronauts each have a light box to maintain their own circadian rhythm, and he described a new LED lighting system being developed for the International Space Station, which will feature 85 tunable light units with three different settings: 238 lux at 4800 K for general vision, 1270 lux at 6500 K for alerting and phase shift, and 90 lux at 2700 K for pre-sleep.

Brodrick concluded the three-day workshop by thanking the attendees and speakers for their input and participation. He noted two additional DOE SSL workshops to be held in 2017—a Connected Lighting Systems Workshop in June, and the 12th annual Technology Development Workshop in November—and encouraged attendees to stay apprised of DOE SSL program activities by visiting www.ssl.energy.gov.