Power plants and energy facilities host some of the most extreme environments anywhere on earth: roaring turbines, blazing furnaces, places where no one dare set foot. How then to find out what’s happening in these environments so we can improve performance?

The answer is sophisticated sensors that relay accurate information from these brutal places.

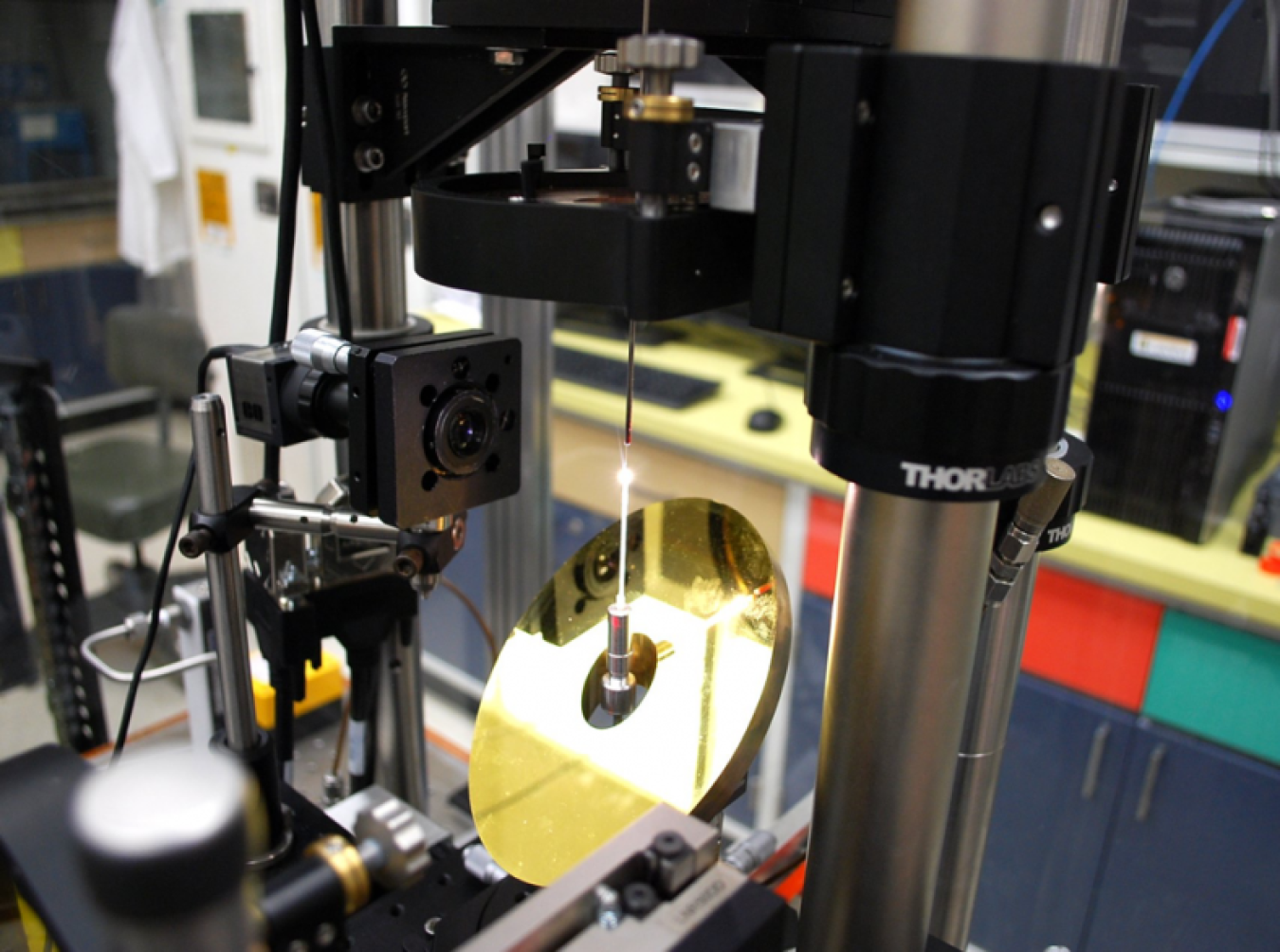

Researchers at the National Energy Technology Laboratory (NETL) are using a wide variety of different types of lasers—as well as waveguides, fiber-optics, and new materials engineered to survive the hottest, toughest environments imaginable—to develop advanced sensors that will enable next-generation energy systems to operate at optimal efficiency, saving massive amounts of energy and lowering emissions of carbon dioxide in the process.

The world of sensors may seem like a small cog in the wheel of complex power systems, but the research stands to offer major benefits. Laser-based sensors could detect leaks or corrosion along hundreds of miles of gas pipelines spanning the country. They could monitor and control high-temperature fuel cells that convert hydrogen to electricity with virtually no emissions. They could even measure the conditions inside industrial-scale gasifiers, which convert coal or other fuels directly into electricity, to improve efficiency, use less fuel, and emit fewer greenhouse gases.

Much of NETL’s work is focused on advancing fossil fuel technologies, which provide most of the world’s power. Sophisticated sensors can provide new measurements and pioneering monitoring strategies to make energy production using these fuels more efficient.

The end result: more power and lower emissions, using fewer resources.