| Directional drilling rig at the STAR Center. |

Operations to develop and manufacture components at the former Pinellas Plant in Florida during the nation’s Cold War–era nuclear weapons program, released solvents to subsurface soils beneath the plant’s 11-acre Building 100. Release areas became sources of dissolved contamination, creating groundwater plumes that extended south and east from the source areas beneath Building 100 and onto private property.

After the Cold War ended, the plant was closed and the site was redeveloped for economic use. However, the contaminated groundwater plumes remained. Today, the U.S. Department of Energy Office of Legacy Management (LM) continues environmental restoration at the site, which is now known as the Young - Rainey Science, Technology, and Research (STAR) Center.

Bioremediation proved to be a successful approach to cleaning up two other STAR Center areas in the past, so enhanced bioremediation was chosen to treat the chlorinated-solvent source areas and groundwater plumes beneath Building 100. The remediation method used a concentrated solution of emulsified vegetable oil (EVO) and bacteria (Dehalococcoides mccartyi or DHM)—diluted with water prior to injection to maximize its subsurface distribution. Once introduced into the subsurface, the bioremediation mixture fermented and produced dissolved hydrogen, which the DHM used to break the bonds on contaminant molecules, resulting in nontoxic end products.

Building 100 is owned by Pinellas County and fully occupied by tenants, so remedial action could not be conducted from inside the building. The best option for implementing enhanced bioremediation beneath the building was to install injection wells via directional drilling, in a horizontal configuration. Also, remediation work was performed during the building’s second shift time frame to minimize disruptions to tenant activities.

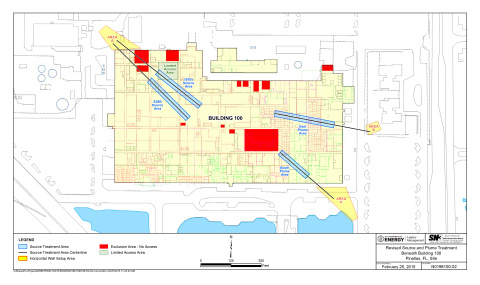

In July, August, and September 2015, eight horizontal wells were installed (as deep and shallow pairs) to target the deep and shallow aquifer portions beneath Building 100 (see Figure 1 above). Installation depths ranged from 13- to 32-feet below surface. Horizontal well lengths ranged from 350 to 470 feet, and the slotted sections of each well ranged from 150 to 250 feet. The slot size and spacing (0.013 inch wide and 1.5 inches long, with one slot per 2-foot well section) were specifically designed for injecting EVO and DHM. The 3-inch diameter wells were constructed of fiberglass reinforced epoxy, a high-strength material that was chosen to limit the potential for well failure during installation.

The property landlord and tenants were kept informed during all field activity phases to address any concerns or questions. Locating subsurface utilities prior to drilling was critical to the project’s success due to the shallow drilling angle (15º below horizontal). Using a supplemental drilling navigation system (the short steering tool) was also critical because radio interference inside the building, combined with no- or limited-access areas, precluded sole use of the typical surface navigation system (see Figure 1).

| Figure 1. Treatment Area Locations Beneath Building 100. |

The horizontal wells were used to inject EVO and DHM in November 2015. Diluted EVO and DHM volumes ranged from 4,500 to 7,500 gallons, depending on slotted well length. These volumes included approximately three well casing volumes of clean water, injected to flush the EVO and DHM from the well. Monitoring wells placed inside and outside Building 100 will be used to monitor project performance.