A new floating, vertical-axis wind turbine platform design may enable offshore wind developers to access the vast U.S. offshore wind resources.

Wind Energy Technologies Office

October 17, 2017

A new floating, vertical-axis wind turbine (VAWT) platform design may enable offshore wind developers in the United States to access the country’s vast deep-water offshore wind resource. The U.S. Department of Energy's Wind Vision Report and National Offshore Wind Strategy explore a scenario in which 86 gigawatts of offshore wind turbines will be installed by 2050. Reaching a competitive LCOE with existing energy sources is essential to achieving these goals and the industry’s commercial success.

A recently completed study by Sandia National Laboratories (Sandia) and Stress Engineering Services identified a VAWT platform design that may help decrease the LCOE of offshore wind. The study compared floating offshore platform designs to identify a cost-optimal floating platform that meets the operational conditions, which includes variables like the operational wind speed range of the VAWT and the site’s wave height distribution.

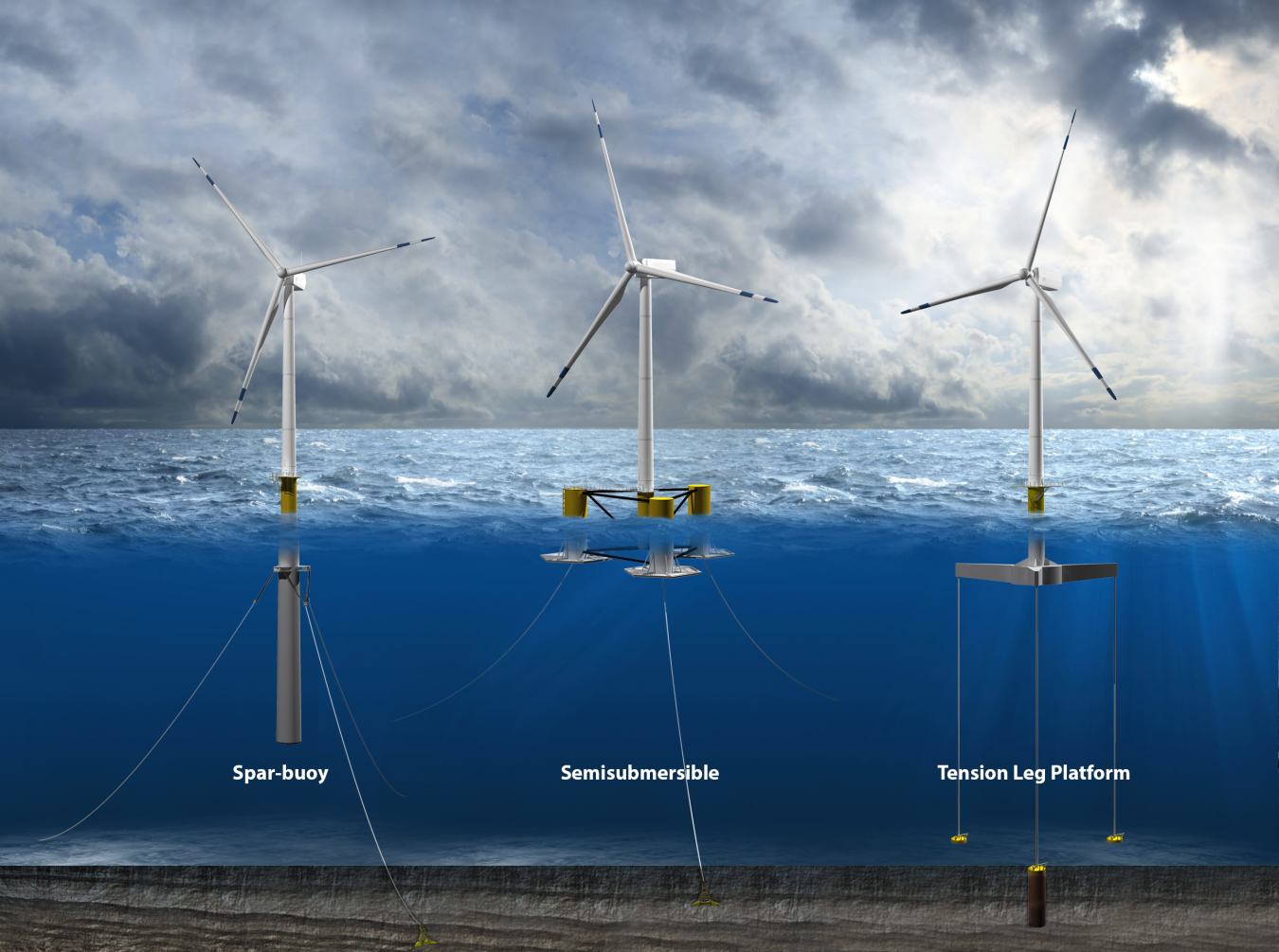

Six designs were initially selected for analysis, chosen based on an initial survey and a first-principles analysis. The initial systems captured the various stability mechanisms available to floating systems: deep-draft ballasting, buoyancy, waterplane (the area of the platform that displaces the water), and tensioned mooring. Each of the six concepts utilizes one or more of these three stabilizing mechanisms in the design.

These tension-leg platform concepts may merit further investigation and consideration for offshore floating wind turbine platforms.

During this initial phase, a tension leg platform (TLP) with a hull made of multiple cylindrical columns was identified as the most promising selection from a cost perspective. Additionally, the TLP mooring scheme offered some performance benefits resulting from reduced platform motions and a smaller mooring anchor footprint.

Shorter mooring cables and lower installation costs reduce the TLP’s cost. The system is designed to be towed offshore with the rotor installed, an advantage that makes installation cheaper. Stress Engineering Service’s favorable platform cost estimate for the VAWT TLP challenges—and is challenged by—trends in commercial floating wind turbine platforms, which have favored semisubmersible or spar concepts.

“The TLP offers some interesting performance benefits resulting from the small roll and pitch motions, such as increased energy capture and reduced inertial loading on the tower and blades,” said Brandon Ennis, Sandia’s Wind Energy Technologies department offshore technical lead. “Combined with a favorable cost estimate, this suggests that these concepts may merit further investigation and consideration for offshore floating wind turbine platforms.”

The platform and VAWT design and cost estimates were used in an LCOE analysis to estimate the total system cost for a floating VAWT offshore wind plant. A horizontal-axis wind turbine has a substantially higher center of gravity and distinct loading conditions, so Sandia’s platform design and analysis would need to be extended to apply to both vertical and horizontal axes.

This analysis produced a range of estimates for VAWT turbines, with low-end values of 15−20 cents per kilowatt-hour for the LCOE, and identified the statistic’s largest contributing sources. Details of the platform identification and selection and system LCOE analyses are documented in a technical report to be released this fall and housed on the Sandia offshore wind webpage.