DOE's NREL is one of a select few accredited labs in the world that measure and rate solar PV module performance.

July 25, 2019

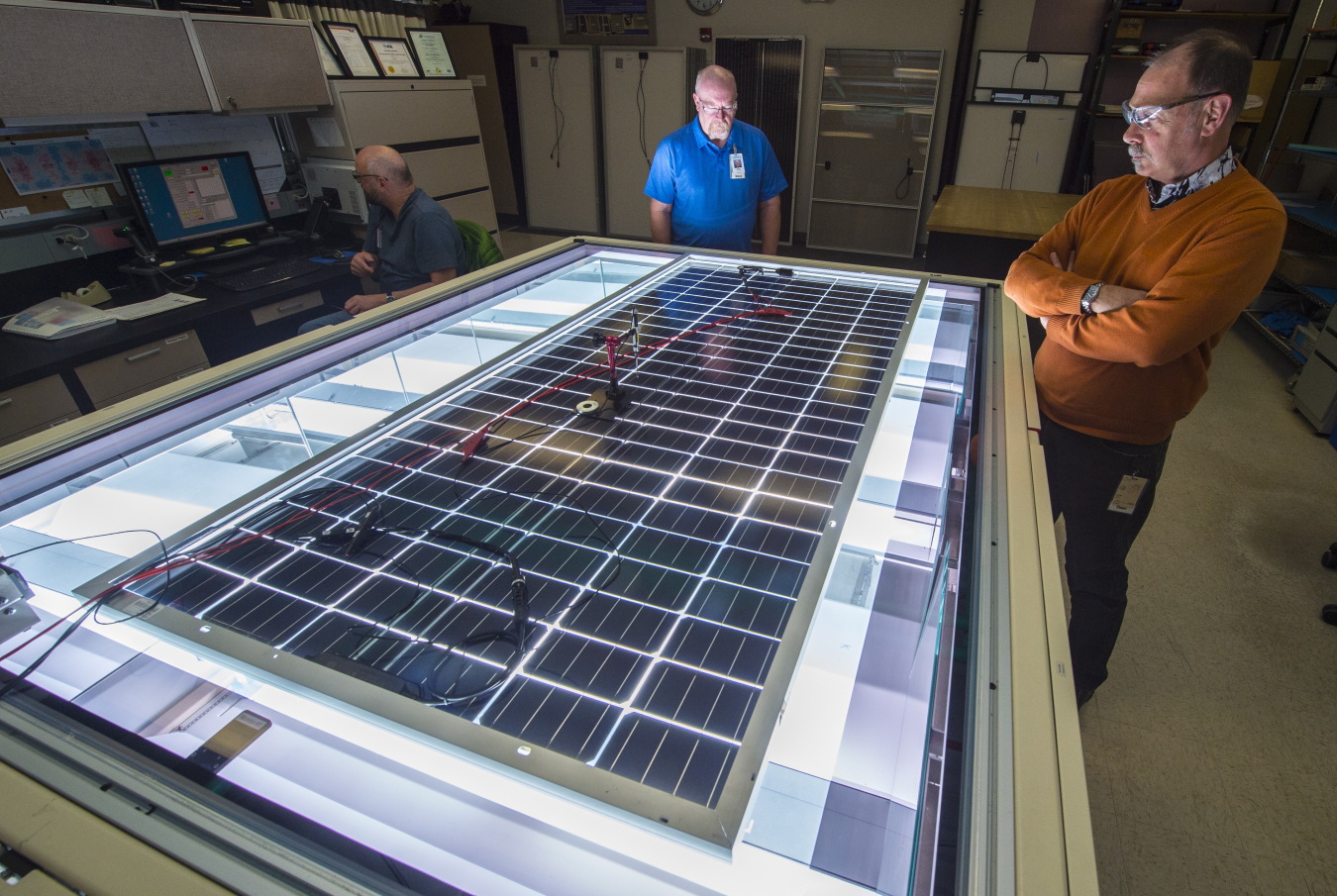

Allen Anderberg, Steve Rummel, and Dean Levi of NREL’s Cell and Module Performance group measure the power output of a PV module on NREL’s solar simulator. Photo by Dennis Schroeder.

The U.S. Department of Energy’s (DOE) National Renewable Energy Laboratory (NREL) is one of a select few accredited labs in the world that measure and rate solar photovoltaic (PV) module performance. Manufacturers rely on module ratings because the ratings estimate how much electricity a panel can create from the sun. By knowing how much electricity solar panels will produce, project developers and plant owners know how many panels they need to buy and the total cost of their system.

The precision of this measurement also affects module prices and manufacturers’ revenue: If a company sells a module at 300 watts when it actually delivers 310 watts of power, the company misses out on potential revenue. In a 2-megawatt utility-scale system with thousands of modules, those extra 10 watts could add up to 500 modules’ worth of power.

As part of a $2.5 million award from the Office of Energy Efficiency and Renewable Energy’s Solar Energy Technologies Office (SETO) in 2015, NREL researchers recently configured the world’s most precise performance measurement for silicon modules. This award builds on decades of support from SETO to advance performance measurement, one of NREL’s core capabilities. As a result, they reduced the uncertainty from 3% to within 1.1%. Though this percentage may seem small, it is quite significant.

To measure panel performance, NREL uses a solar simulator—a table illuminated by lamps that mimic the sun’s spectrum. However, the spectrum of a lamp cannot exactly match that of the sun, and the light intensity from the lamps may vary across a large area because of material imperfections, how the lamps are arranged, or other factors. The quality of the light determined by the intensity at each wavelength affects how a panel generates current and how much electric charge flows. Variability in light and temperature creates uncertainty.

To reduce the uncertainty of their measurements, the researchers now take the module outdoors on a cloudless day to a place with no shadows from trees or buildings and measure its current under sunlight. Then they bring the module back to the lab, use the current they measured outdoors to set illumination levels in the simulator, and measure the power output. This ensures the difference between the combined measurement and the true illumination value of the sun is as low as possible. The team calls this process “module self-reference.” These measurements help to determine NREL’s Champion Photovoltaic Module Efficiency Chart, which ranks modules with the highest confirmed efficiencies.

NREL’s improvement in performance characterization has significantly reduced the margin of error, which helps the solar industry set accurate module prices and expectations for output. For a PV manufacturer, the 3% to 1.1% difference could increase profits by up to about $5 million per gigawatt of modules produced. And installers, project developers, financiers, and consumers will all have more accurate module calibrations so they can plan to use their assets better—and be reassured that the modules will deliver as much power output as their ratings say they will.

Learn more about SETO’s photovoltaics research.