Startup Tau Science’s scanner shows signs of module damage and keeps repair crews safe.

December 3, 2018When photovoltaic (PV) modules show signs of wear and tear in the field, a maintenance crew has to unplug them and take images one at a time to detect module defects. It’s a slow process that exposes the crew to high voltage, which introduces safety issues, not to mention lost operation time and increased costs for solar developers.

Solar startup Tau Science has a solution to this problem.

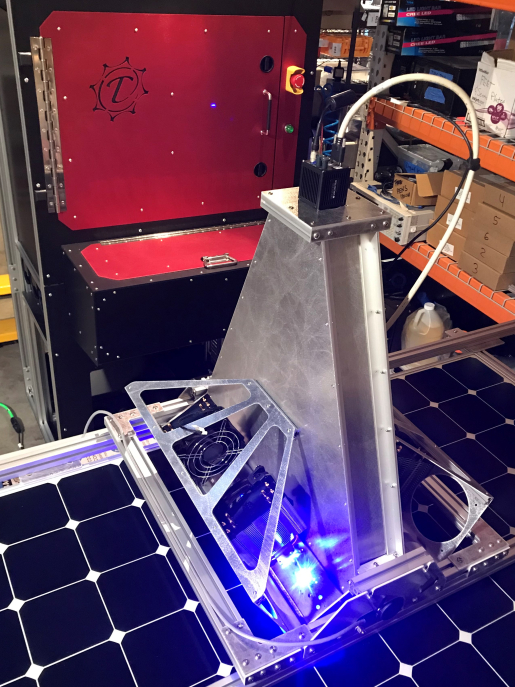

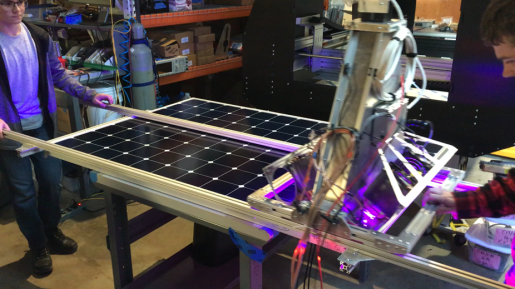

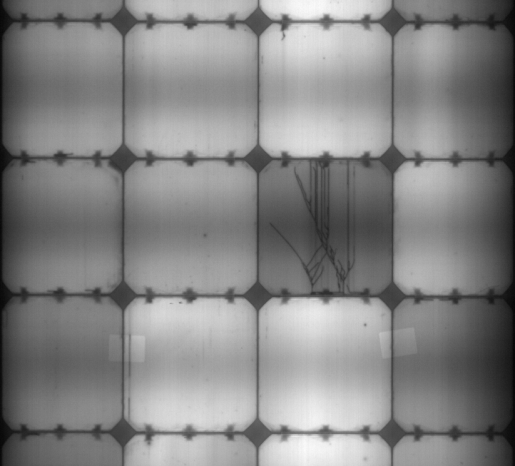

The company developed a high-speed non-contact scanner that detects signs of degradation in outdoor PV arrays, such as cracking, moisture intrusion, and corrosion. To do this, the scanner takes high-resolution images of the cells without any electrical connections, putting an end to manual high-voltage tests. The ability to capture the images depends on the flow of electrical current within the cell, so if the flow is disrupted by cracks or corrosion, the cell won’t glow—a sign that the PV module needs repair.

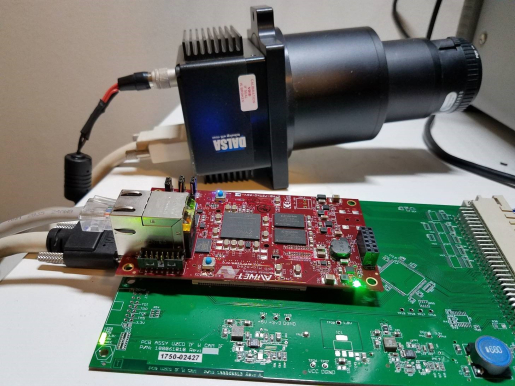

The device—comprised of a camera, light source, and a software system that controls them—instantly collects data, analyzes the images, and sends summary results to a customer, leading to a faster, less-expensive diagnosis. This also speeds the insurance claims process that results when a system is damaged, reducing operation delays and reliance on expensive inspections.

The early research, funded in 2013 by the U.S. Department of Energy Solar Energy Technologies Office (SETO) through a small business research program, focused on developing the basic non-contact scanner technique: using a light source that measures the spectral response of a solar cell, or the cell’s ability to convert each color of light into electricity. The scanner uses blue light to show defects near the cell’s surface, while near-infrared light shows defects toward the back of the cell.

Tau Science later learned that Steve Johnston, a scientist at the National Renewable Energy Laboratory (NREL), had invented a technology called contactless electroluminescence that injects light into a solar cell, allowing a camera to photograph dark regions. The company knew it could enhance the scanner and turned to SETO to facilitate technology transfer and licensing.

SETO and Tau Science collaborated in 2017 to design a lightweight, durable device that can handle large image datasets with automated software algorithms. SETO funded the hardware for the first prototype, including cameras, light sources, and control electronics—as well as the efforts to miniaturize those electronics, which need to be lightweight so workers can lift the device. Tau Science then worked with SunPower to test the scanner on PV modules in San Jose, California, where the team learned the scanner needed greater sensitivity.

The new prototype increased the sensitivity of the device by about 40 times and will soon be tested on outdoor modules in Oregon, Florida, and Colorado. The feedback received will support the team’s efforts to further refine the prototype and look for customers, moving the non-contact scanner one step closer to market.

Learn more about the solar projects in the Small Business Innovation Research/Small Business Technology Transfer program.