In late 2019, WPTO gathered with stakeholders to improve generation and environmental performance of the recently upgraded High Rock Hydroelectric Facility.

June 29, 2020New technologies increase water oxygen levels and improve monitoring, providing environmental benefits for the Yadkin

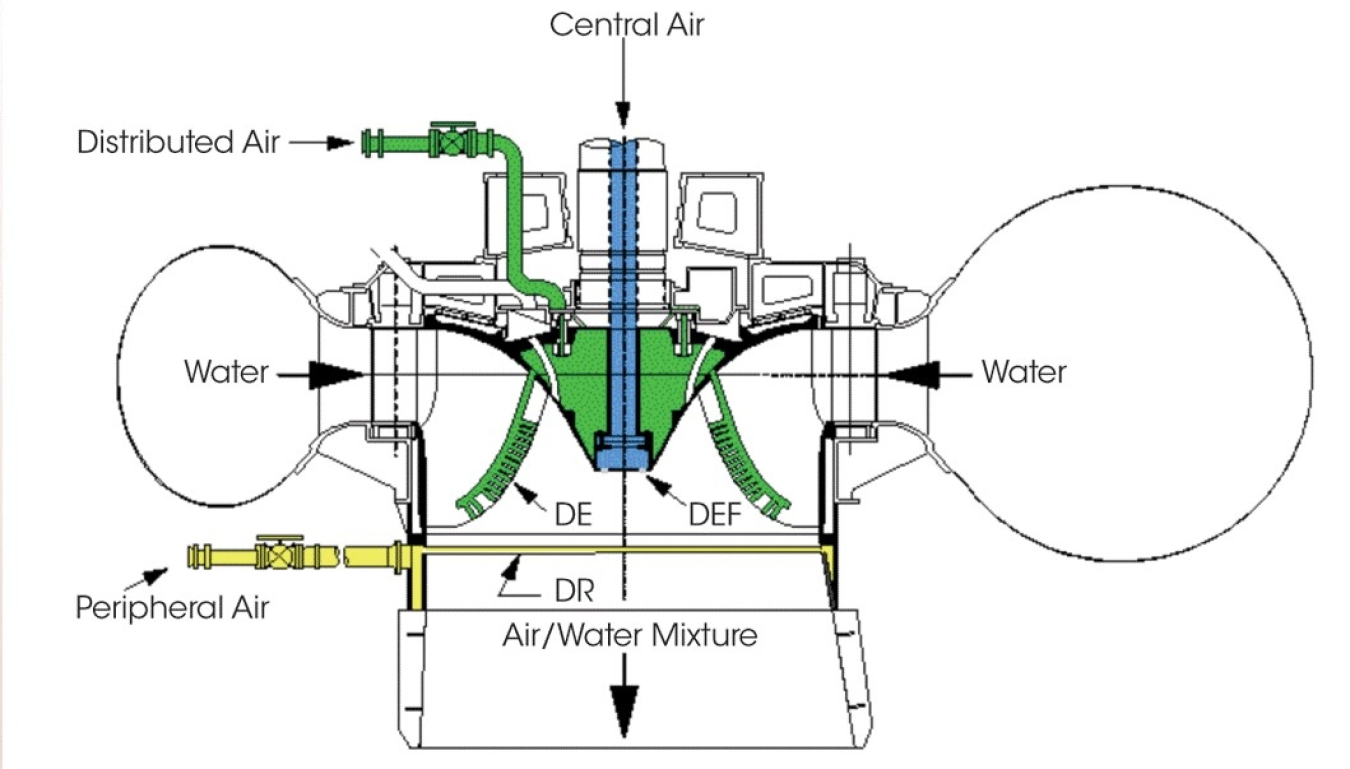

In late 2019, the DOE’s Water Technologies Office (WPTO) gathered with stakeholders to improve generation and environmental performance of the recently upgraded High Rock Hydroelectric Facility. Located on the Yadkin River outside Charlotte, North Carolina, the upgraded High Rock facility showcased a new type of hydropower turbine, designed by General Electric (GE), that directly infuses dissolved oxygen into the water. In addition to GE, project partners included Eagle Creek Renewable Energy (formerly Cube Hydro) and the Pacific Northwest National Laboratory (PNNL).

As part of the upgrades, Eagle Creek developed and installed a new proprietary linear aeration valve to inject oxygen into the river during non-generation periods. The performance of these systems was assessed using a new, mobile dissolved oxygen monitoring system developed by PNNL. Combined, these technologies help to increase dissolved oxygen in the river and also enable High Rock to more effectively monitor the quality of the water near the plant.

Dissolved oxygen in rivers is one of the principal environmental concerns around hydropower facilities, particularly in the southeastern United States. Oxygen in rivers is extremely important for the health of fish and other freshwater organisms—including the spotted bass, redbreast sunfish, and flathead catfish that live in the Yadkin. The High Rock facility has experienced difficulties maintaining minimum levels of dissolved oxygen during challenging drought seasons or when the facility was passing a lot of water through the turbines. Now, when the plant is generating, GE’s turbine will be able to increase aeration, and during non-generation periods, Eagle Creek’s valve is specially designed to inject oxygen into the water.

Some of the underlying science that informed the development of these technologies was funded by DOE from 2010–2012 and took place at St. Antony Falls Laboratory at the University of Minnesota. Results from the lab’s research and improvement to computational tools have helped improve air bubble measurement and modeling techniques that are used to design effective systems to inject air into water. These capabilities enabled Alstom Hydro Global Technology Center (now part of GE) to develop a first-of-its-kind 13.4-megawatt aerating turbine that was installed at High Rock in 2019. A second unit was completed in early 2020, and the project team plans to install a third unit by the end of 2020. At that time, Eagle Creek will reevaluate the water quality of the Yadkin River and assess what may or may not be needed for their other plants.

The new mobile dissolved oxygen monitoring system developed by PNNL researchers will make these improvements easier to observe. PNNL’s system is distinguished in its ability to nimbly undertake water sampling missions in and around the water intakes and downstream areas of a dam, which can be complex and potentially dangerous to navigate and manually sample. The device will continue to undergo testing and additional deployments in the coming years.

The work the partners engaged in during these efforts highlight the benefits of public-private collaborations and efforts to simultaneously improve both energy generation and the health of the nation’s rivers.