To carry out the technical vision of Frontier Observatory for Research in Geothermal Energy (FORGE), the University of Utah manages and coordinates the solicitation for and administration of research and development (R&D) activities at the Utah FORGE site in coordination with the Office of Geothermal. Recurring solicitation cycles started in 2020.

Technical research recommendations to guide FORGE’s operation as an enhanced geothermal systems (EGS) research site are shared in the 2019 Frontier Observatory for Research in Geothermal Energy: A Roadmap. The FORGE Roadmap describes discrete actions that could be carried out at FORGE to overcome key technical challenges necessary for EGS to be reliable and reproducible.

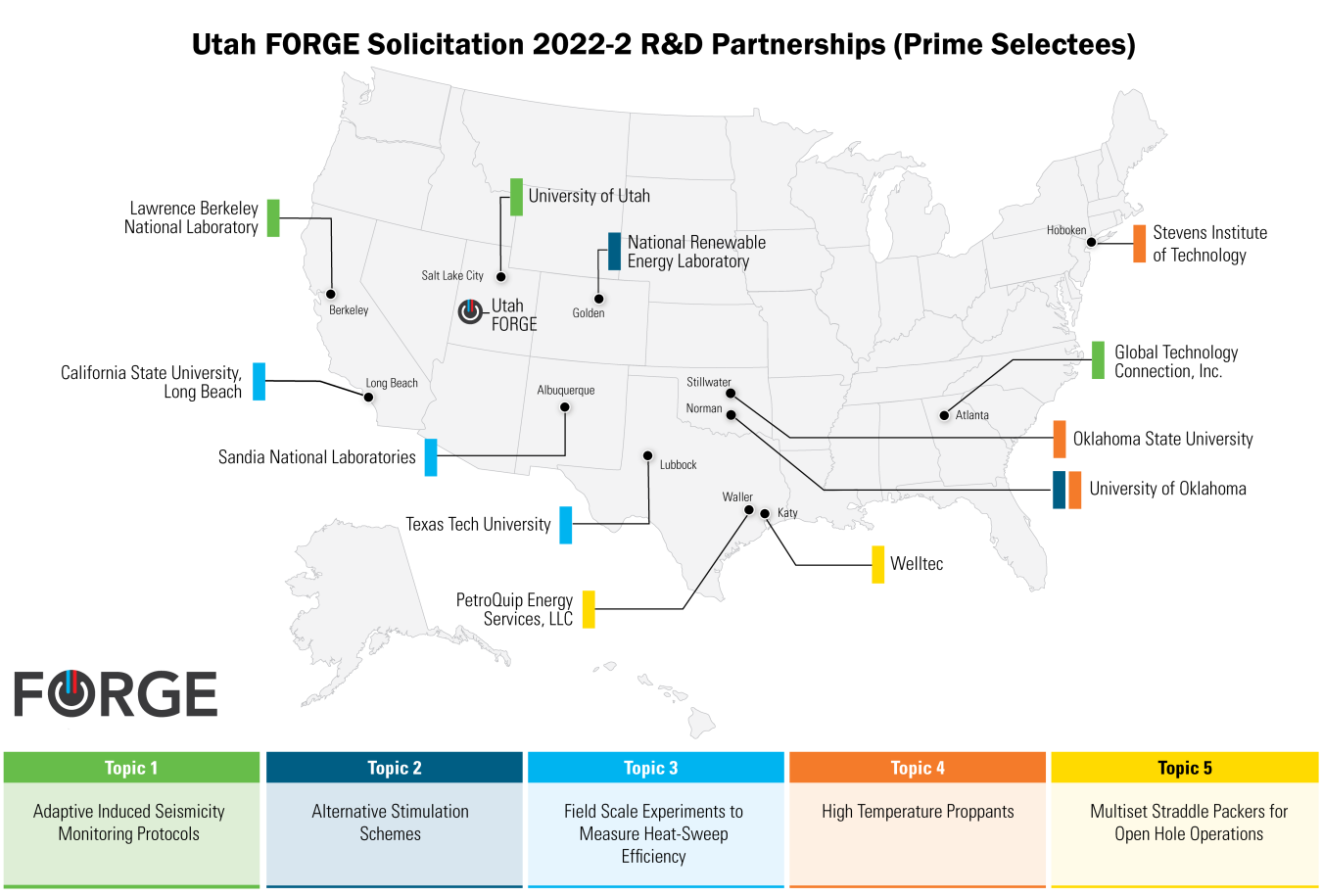

FORGE Solicitation 2022-2

In August 2022, Utah FORGE announced its second solicitation of up to $44 million for R&D projects. This solicitation covers testing and evaluation of new and innovative EGS tools, techniques, and supporting science in the following EGS lifecycle categories:

- Reservoir characterization (coupled imaging, drilling for interrogation and monitoring, high-temperature tools and sensors)

- Reservoir creation (formation access, fracture characterization, zonal isolation, stimulation technologies)

- Reservoir sustainability (long-term testing, monitoring, and operational feedback).

Thirteen selected projects were announced on November 14, 2023:

Adaptive Induced Seismicity Monitoring Protocols

- Global Technology Connection, Inc. | Atlanta, GA

- Lawrence Berkeley National Laboratory | Berkeley, CA

- University of Utah | Salt Lake City, UT

Alternative Stimulation Schemes

- National Renewable Energy Laboratory | Golden, CO

- University of Oklahoma | Norman, OK

Field Scale Experiments to Measure Heat-Sweep Efficiency

- California State University, Long Beach | Long Beach, CA

- Sandia National Laboratories | Albuquerque, NM

- Texas Tech University | Lubbock, TX

High Temperature Proppants

- Oklahoma State University | Stillwater, OK

- Stevens Institute of Technology | Hoboken, NJ

- University of Oklahoma | Norman, OK

Multiset Straddle Packers for Open Hole Operations

- PetroQuip | Waller, TX

- Welltec | Katy, TX

These selected projects are now in negotiations with Utah FORGE. Learn more on the Utah FORGE website.

For publicly accessible data, check out Utah FORGE data in the Geothermal Data Repository and Utah FORGE's Wiki page.

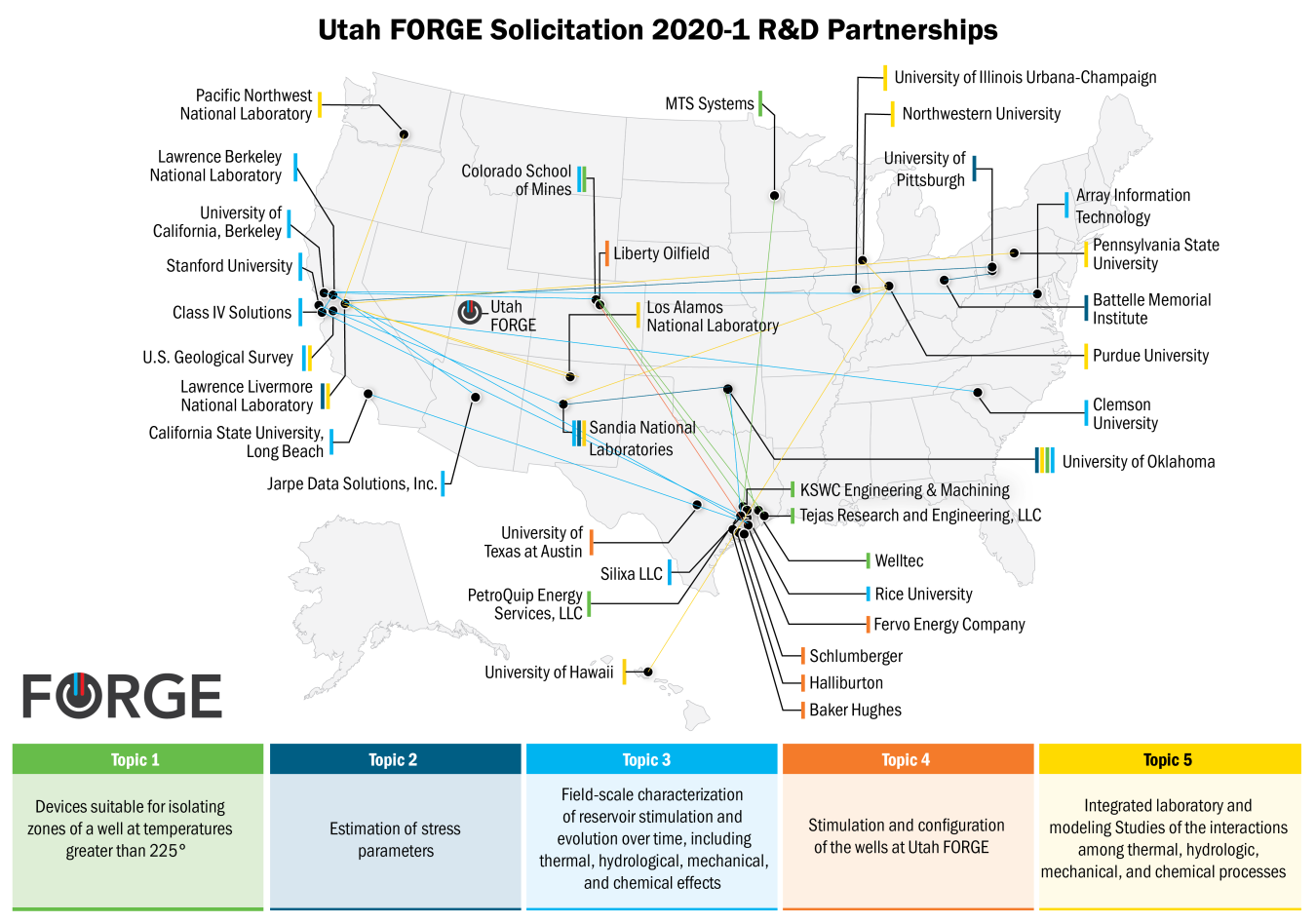

FORGE Solicitation 2020-1

In February 2021, the FORGE team announced the first portfolio of competitively selected R&D projects. Submitted in response to Solicitation 2020-1, 17 projects in five topics will receive U.S. Department of Energy funding of up to $49 million over the next three years.

This portfolio includes testing and evaluation of new and innovative enhanced geothermal systems (EGS) tools and techniques in the categories of characterization, creation, and sustainability of geothermal reservoirs.

Topic 1: Devices Suitable for Sectional (Zonal) Isolation Along Both Cased- and Open-Hole Wellbores Under Geothermal Conditions

Topic 1 projects will aim to develop devices or systems that are operational at temperatures up to 225°C and allow geothermal operators to target specific areas for geothermal reservoir creation and improvement. The ability to manage flow into and out of specific zones will reduce the financial and operational risks of EGS development.

- Welltec (Katy, Texas): The team aims to develop and test a state-of-the-art, all-metal system for EGS reservoir creation and management. The system will be designed to manage and adjust flow into and out of specific sections of a geothermal well during its operational lifetime.

- Team member: University of Oklahoma (Norman, Oklahoma)

- PetroQuip Energy Services (Waller, Texas): For this project, researchers will design, build, and test two types of downhole zonal isolation tools—a locking bridge plug and an open-hole packer. Both tools will be designed to work with proppant-bearing stimulation fluids when creating and improving EGS reservoirs and perform for periods of up to 12 months in EGS geothermal reservoir conditions.

- Team member: MTS Systems (Eden Prairie, Minnesota)

- Colorado School of Mines (Golden, Colorado): This team will design, build, and test a downhole zonal isolation tool called a “sliding sleeve” that can be used to adjust flow. The team will also build a downhole tractor to slide the sleeves; and the tractor will have the capability to measure flow from specific zones.

- Team members: Tejas Research and Engineering, LLC (The Woodlands, Texas), KSWC Engineering and Machining (Houston, Texas)

Topic 2: Estimation of Stress Parameters

Performers under this topic will conduct analysis of subsurface stress at the Utah FORGE site. They will design and implement stress measurement plans to support and optimize EGS reservoir creation at the site.

- Battelle Memorial Institute (Columbus, Ohio): This team will provide a detailed and holistic view of the subsurface stress and its variability at the Utah FORGE site using three different methods—1) machine learning trained by experimental data obtained via laboratory tests on rocks; 2) direct stress measurement via hydraulic fracturing tests in a new geothermal well; and 3) numerical modeling.

- Team member: University of Pittsburgh (Pittsburgh, Pennsylvania)

- Lawrence Livermore National Laboratory (Livermore, California): This team will develop high-fidelity estimations of stress at the Utah FORGE site through state-of-the-art modeling integrated with both field and laboratory data. The team will use detailed models to simulate fracture initiation and propagation under various scenarios, including for a range of rock properties and wellbore layouts.

- Team member: University of Pittsburgh (Pittsburgh, Pennsylvania)

- University of Oklahoma (Norman, Oklahoma): This team aims to develop a technology that can determine stress at the FORGE site by integrating wellbore data, a reservoir-scale stress estimation method, and data collected from a diagnostic test performed on core obtained from the well.

- Team member: Sandia National Laboratories (Albuquerque, New Mexico)

Topic 3: Field-Scale Characterization of Reservoir Stimulation and Evolution Over Time, Including Thermal, Hydrological, Mechanical, and Chemical Effects

Performers under this topic will develop advanced, complementary characterization methods and processing techniques to support existing data at the Utah FORGE site. These methods and techniques will help us understand how a geothermal reservoir develops and changes over time.

- Clemson University (Clemson, South Carolina): The team will use an array of highly sensitive strainmeters to measure extremely small, shallow subsurface deformations during EGS reservoir stimulations at the Utah FORGE site. The team will also explore the technical feasibility of a strainmeter designed to withstand geothermal temperatures.

- Team member: U.S. Geological Survey (Menlo Park, California)

- Stanford University (Palo Alto, California): The project aims to refurbish a tool that can monitor flow within the FORGE wells by measuring changes in water properties. The tool will allow researchers to determine the location and the importance of flowing fractures that result from reservoir creation, providing a way to monitor for geothermal reservoir changes over time.

- Team member: Sandia National Laboratories (Albuquerque, New Mexico)

- Lawrence Berkeley National Laboratory (Berkeley, California): The project team will use a variety of data and a quantitative analytical process called a “joint inversion” to estimate the thermal, hydrological, mechanical, and chemical processes that control reservoir growth and change over time.

- Team members: Array Information Technology (Greenbelt, Maryland), Jarpe Data Solutions, Inc. (Prescott Valley, Arizona), Colorado School of Mines (Golden, Colorado), University of California, Berkeley (Berkeley, California)

- Rice University (Houston, Texas): The project team will deploy a state-of-the-art fiber optic monitoring system that can continuously monitor temperature, stress, and acoustic signals along the wellbore. These data, when combined with data collected from surface seismic sources and well diagnostic tests, will map flowing fractures and how they change during reservoir stimulation.

- Team members: Silixa (Houston, Texas), Class VI Solutions (Oakland, California), Lawrence Berkeley National Laboratory (Berkeley, California), California State University, Long Beach (Long Beach, California), University of Oklahoma (Norman, Oklahoma)

Topic 4: Stimulation and Configuration of the Wells at Utah FORGE

Projects funded under this topic will develop and test innovative stimulation techniques and methodologies in Utah FORGE wells. Resulting data and analysis will inform the location and geometry of the second production well at the site.

- Fervo Energy Company (Houston, Texas): The project team will design a multistage “plug-and-perf” hydraulic stimulation for use at the Utah FORGE site. Data and analysis from a stimulation test at another site will inform the proposed design of the next FORGE stimulation.

- Team members: Schlumberger (Houston, Texas), Halliburton (Houston, Texas), Baker Hughes (Houston, Texas), Liberty Oilfield Services (Denver, Colorado)

- University of Texas at Austin (Austin, Texas): Enabled by data collected from a state-of-the-art fiber optic monitoring system, the project team will make recommendations for the next highly deviated FORGE well. The recommendations will inform well spacing, stimulation design, injection rates, and other optimizations at the Utah FORGE site.

Topic 5: Integrated Laboratory and Modeling Studies of the Interactions Among Thermal, Hydrological, Mechanical, and Chemical Processes

Projects under this topic area will improve models by incorporating experimental activities and measurements of rock and reservoir properties collected from the Utah FORGE site. These models will determine fracture behavior, permeability evolution, and heat transfer over time at Utah FORGE and develop an improved understanding of which properties are critical for the development of EGS.

- Pennsylvania State University (State College, Pennsylvania): This project will identify the acoustic signs resulting from the movement of rock along fractures, or shearing, and the resultant permeability changes over time. These fractures can be linked to preexisting stresses and predict important features of resulting seismicity. These linkages can be applied to EGS reservoirs to drive successful reservoir stimulation, production, and management.

- Lawrence Livermore National Laboratory (Livermore, California): The goal of this project is to create and apply a thermo-hydro-mechanical-chemical model that includes induced seismic activity in EGS reservoirs. The project also seeks to reduce uncertainties and better predict and mitigate seismic hazards.

- Team members: Pacific Northwest National Laboratory (Richland, Washington), Los Alamos National Laboratory (Los Alamos, New Mexico), Pennsylvania State University (State College, Pennsylvania)

- U.S. Geological Survey (Menlo Park, California): With this project, researchers seek to identify the processes that control how fractures change over time and under various conditions. A better understanding of these processes will be used to develop models for predicting how fractures may change over time at hydrothermal conditions.

- University of Oklahoma (Norman, Oklahoma): By conducting lab experiments on FORGE rocks, this project team aims to improve the understanding and control of coupled thermo-hydro-mechanical processes in geothermal reservoir development and demonstrate their impact on fracture closure pressures interpretations.

- Purdue University (West Lafayette, Indiana): This project will develop and test a model that describes the links between deformation, seismic events, and chemical reactions in EGS reservoirs. Through the integration of experimental data and mechanics-driven theory, this model will be used to help design for optimal heat recovery at Utah FORGE and enhance understanding of how fractures change over time.

- Team members: Sandia National Laboratories (Albuquerque, New Mexico), University of Hawai´i (Honolulu, Hawai´i), University of Illinois at Urbana-Champaign (Champaign, Illinois), Northwestern University (Evanston, Illinois)