DOE is awarding $31.8 million for seven project teams that will demonstrate how advanced construction techniques integrated with energy efficient technologies and practices can seed the next generation of building retrofit solutions.

March 14, 2022The U.S. Department of Energy (DOE) is awarding $31.8 million for seven project teams that will demonstrate how advanced construction techniques integrated with energy-efficient technologies and practices can seed the next generation of building retrofit solutions.

The DOE Building Technologies Office’s Advanced Building Construction (ABC) Initiative is working to change the way buildings are constructed and renovated. ABC focuses on developing industrialized construction innovations that can quickly deliver efficient, affordable, and appealing new buildings and retrofits at scale. Pairing approaches like offsite factory-based construction with advanced building technologies, such as prefabricated high-performance wall panels and packaged HVAC and water heating pods, ABC seeks to enable rapid deployment of advancements in the construction sector—changes that can simultaneously help modernize the sector and address the climate crisis.

DOE selected seven project teams through this Advanced Building Construction funding opportunity announcement to demonstrate next-generation whole-building retrofit approaches that will reduce thermal energy loads by at least 50-75%. With demonstrations planned across the country, these projects span a wide range of climates, geographies, building types, and business and workforce models. The recipient teams—made up of diverse partnerships of U.S. technology firms, manufacturers, nonprofits, academia, public housing authorities, designers, engineers, and architects—will not only demonstrate and test new approaches and technologies but will work, train, and learn together to develop common and durable practices for a robust building retrofit workforce.

Together, these seven teams will bring ABC innovations to more than 30 existing buildings across the country, with the majority located in low-income communities that need cleaner and more affordable homes.

The selectees are:

The University of Central Florida Board of Trustees – Orlando, Florida

- Planned Location of Buildings: Maine, Texas, Oregon, Colorado, North Carolina, and Georgia

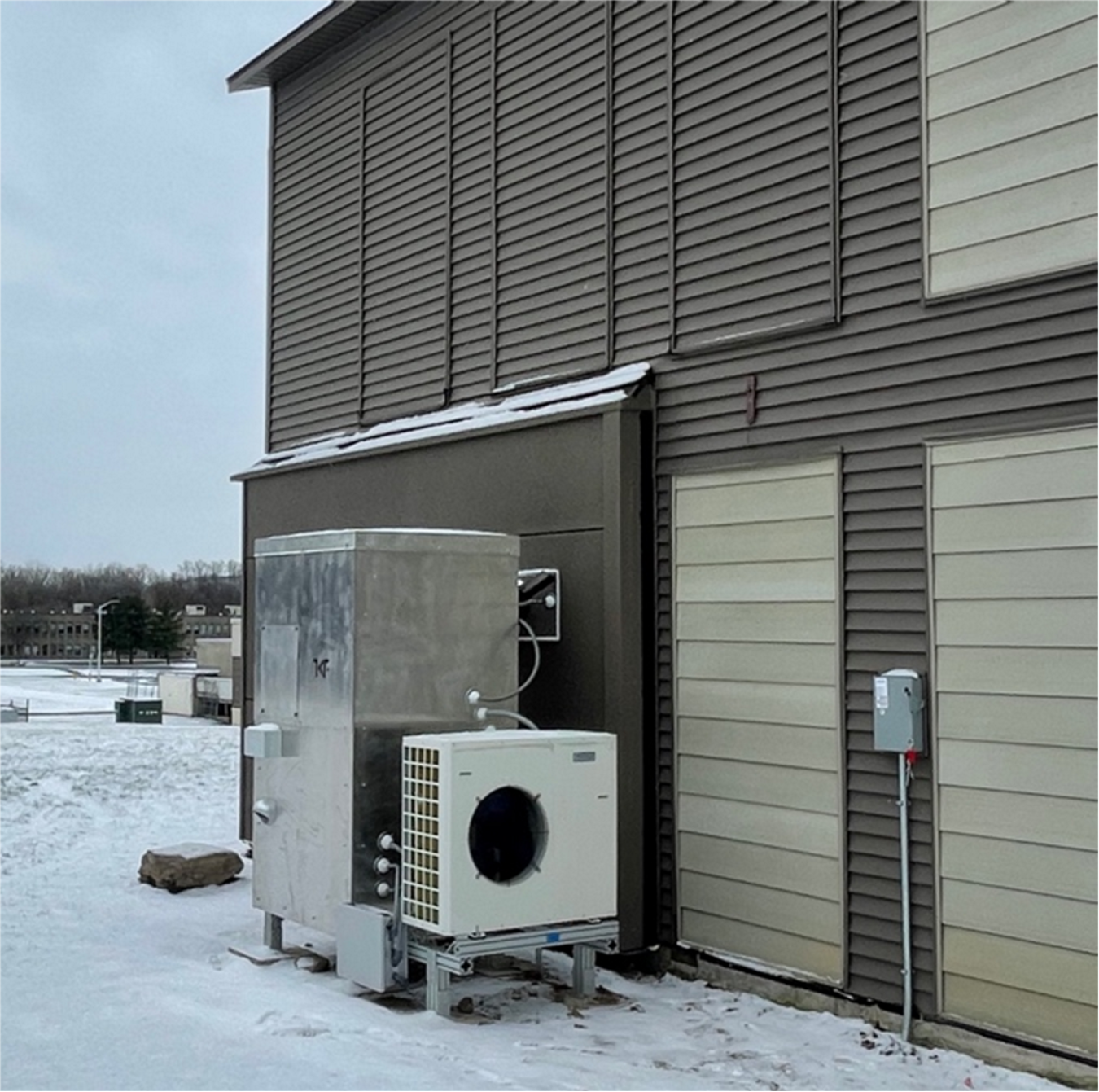

The University of Central Florida, in partnership with the National Association of State Energy Officials, Rheem Manufacturing, and Resident Owned Communities, U.S.A. (ROC) will retrofit eight manufactured housing units and four single-family homes with a technology pod, consisting of high-efficiency minisplit heat pumps and high-efficiency heat pump water heaters that are partially powered by an independent photovoltaic system. The university aims to develop a commercialization plan to manufacture and deploy the strategy at scale across different climate zones. Solutions will also include cost-effective low-cost improvements to ductwork, sealing, and insulation.

Fraunhofer USA Center for Manufacturing Innovation – Brookline, Massachusetts

- Planned Location of Buildings: Massachusetts, Pennsylvania, and Vermont

The Fraunhofer USA Center for Manufacturing Innovation, in collaboration with Green Building Alliance, Steven Winter Associates, and a variety of U.S. suppliers, will demonstrate a super-insulated wall retrofitting process. The team will combine prefabricated panel-block wall insulation with a portfolio of high-performance building technologies to create a comprehensive, single-family deep energy retrofit that enhances the appearance of exterior walls and windows. The project will use digital tools like computer-aided design techniques for manufacturers and virtual reality training for installers to minimize the costs. The team seeks to deliver the solution to five facilities in cold and very cold climates in under two weeks at an installed cost of $25/ft2.

Oak Ridge National Laboratory – Oak Ridge, Tennessee

- Planned Location of Buildings: Knoxville, Tennessee

Oak Ridge National Laboratory, in collaboration with the University of Tennessee at Knoxville, KCDC, LG, IACMI, Pella, Composite Alliance Group, and DB Technologies, will demonstrate a modular, exterior panel retrofit solution with advanced manufacturing techniques on 12 single-family attached duplexes and one small commercial site. The project applies a rapid measurement of home facades, an easy-to-install panel design, and state-of-the-art integrations with HVAC equipment and controls. This team seeks to demonstrate a pathway to unleash high-quality and affordable energy-efficient buildings and jobs in the local area, including at the Boys and Girls Club of Knoxville, at an installed cost of $15/ft2.

Syracuse University – Syracuse, New York

- Planned Location of Buildings: Syracuse University Campus, New York

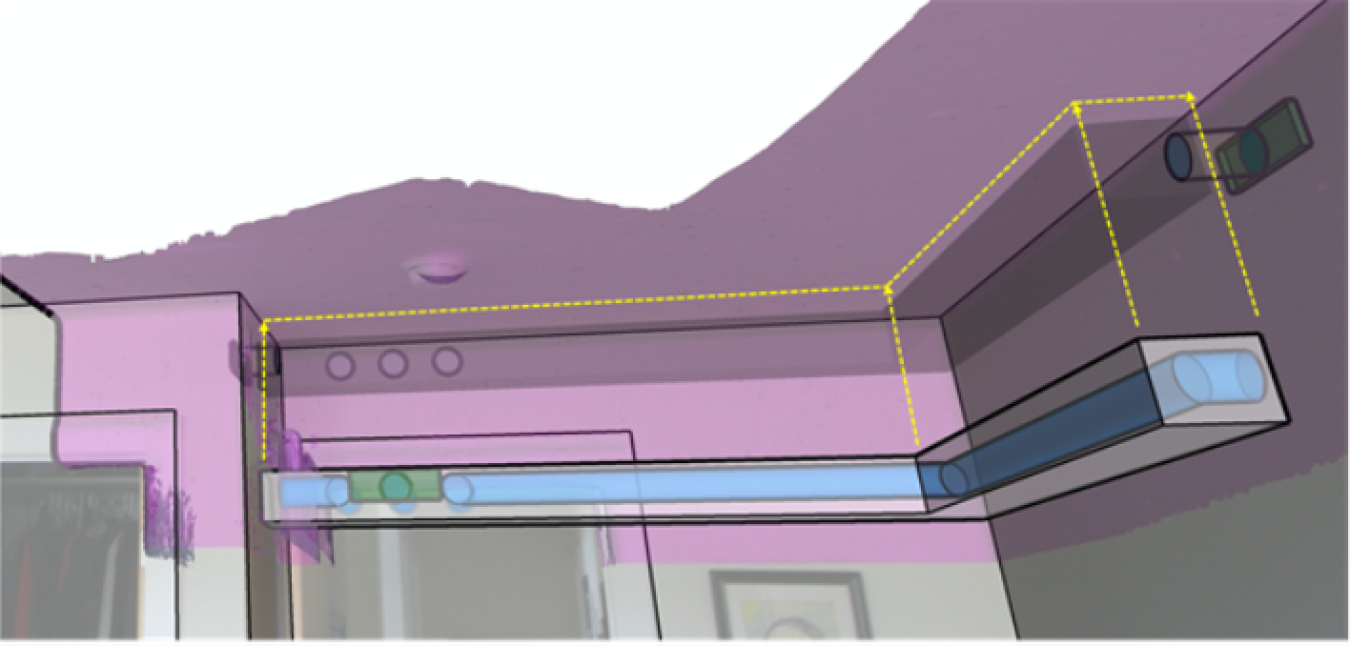

Syracuse University, in collaboration with Signetron, Taitem Engineering, Cycle Architecture, TK Fabricate, Tremco, FunForm, and VIP Structures, will demonstrate a solution for retrofitting entire dormitories that could be widely applicable to the multifamily housing sector. Syracuse’s solution integrates a highly insulated, prefabricated envelope panel, a mechanical solution for performance monitoring of existing heating, cooling, ventilation, and domestic hot water equipment, and 3D information capture to model and configure panel fabrication in a more optimized workflow. The project aims to deliver the R-30 airtight panel solutions in cold/very cold climate regions.

Home Innovation Research Labs Inc. – Upper Marlboro, Maryland

- Planned Location of Buildings: Albany, New York

Home Innovation Research Labs will work with ORNL, Kingspan, the Structural Insulated Panel Association, and the Albany Housing Authority to retrofit three low-rise, multifamily residences in Albany, New York. The project will use a nail-based system to deploy both retrofitted insulated panels and vacuum insulated panels that are comparably lighter, smaller, and less expensive to increase the R-value of exterior walls by a factor of four. The technology could benefit the nearly 2 million existing, older multifamily buildings of similar vintage built in the 1970s and '80s across the United States.

National Renewable Energy Laboratory (NREL) – Golden, Colorado

- Planned Location of Buildings: Arvada, Colorado

NREL with Tremco, Trimble, Microsoft, IBACOS, CanmetENERGY, and Colorado State University will develop a system for tailoring prefabricated hardware and apply it to two, 13-unit low-rise multifamily buildings with the help of novel software applications. The engineering design will be customized with machine learning techniques using site data, and the fabrication process of insulation panels will be done offsite, using 3D virtual reality tools. The workflow includes a virtual expert for real-time installation guidance and expects to reduce construction time and project costs by 50%. The projects will take place at facilities where more than 90% of the residents qualify for a state housing voucher program.

Rocky Mountain Institute (RMI) – Boulder, Colorado

- Planned Location of Buildings: Cambridge, Massachusetts

RMI, in partnership with Open Market ESCO, Signetron, Staengl Engineering, TKFabricate, Lawrence Berkeley National Lab, and Tremco, will apply an integrated whole building retrofit solution to a low-income, nine-story, mid-rise multifamily residence consisting of 120 housing units. The approach consists of prefabricated, insulated envelope panels, mechanical system pods, and prefabricated ductwork that are integrated with digital workflow automation techniques to streamline the design, manufacturing, and delivery processes. The project incorporates financing and business model development.

To follow the development of these projects and learn more about BTO’s Advanced Building Construction Initiative, subscribe to BTO’s news updates or visit the Advanced Building Construction Initiative website. You can also join the ABC Collaborative, which connects companies working in prefabricated, modular, and other industrialized construction techniques with building owners, developers, financiers, utilities, and researchers to modernize the construction industry and buildings sector.