BTO’s 5-year progress report reviews the outcomes of its research funding and partnerships and identifies successfully commercialized technologies that resulted in domestic sales or use in the United States.

September 21, 2022Today, the U.S. Department of Energy (DOE) and Carnegie Mellon University opened the Global Clean Energy Action Forum, a global event that has drawn 5,000 people from around the world to Pittsburgh, Pennsylvania, where they’re convening to turn energy ambition into action and accelerate the transition toward a more secure energy future. At this event, more than 300 CEOs and many climate financiers and philanthropists are joining the world’s energy ministers, energy innovators, and other leaders to work toward the same collective goal: “rapid innovation and deployment” of emerging energy technologies that “stand to reduce global emissions while supercharging the energy economy.” One of the event’s primary goals is to “demonstrate progress in moving along the innovation-to-deployment continuum at an unprecedented pace and scale to meet climate goals, and to innovate with a purpose.” To demonstrate its own progress in support of these goals, DOE’s Building Technologies Office (BTO) released one of its most anticipated progress reports today, Technologies and Innovations Enabled by the U.S. Department of Energy Building Technologies Office 2015-2020.

America’s nearly 130 million residential and commercial buildings use 40% of the nation’s energy and 75% of its electricity. For over three decades, BTO has supported the development and market adoption of cost-effective technologies and practices that reduce the energy intensity of homes and commercial buildings. BTO strategically funds the research, development, demonstration, and regulation of these technologies and practices, a pipeline of activities that collectively catalyze innovations and accelerate the adoption of “high-impact” building technologies and practices that play essential roles in meeting national energy goals.

BTO regularly measures its progress by publishing a report that reviews the outcomes of its research funding and partnerships to highlight successfully commercialized technologies, defined as processes, techniques, designs, machines, tools, materials, or software that were developed with funds provided at least in part by BTO that have resulted in domestic sales or are in use in the U.S. This year’s report highlights 28 such products that resulted in the launch of a commercial product and remained on the market as of March 2021. These products can be found in nearly every corner of a building, from improved appliances, windows, and walls to new lighting and HVAC systems with advanced sensors and controls that can coordinate and optimize the energy performance of entire buildings and even communities. Here are some of their stories.

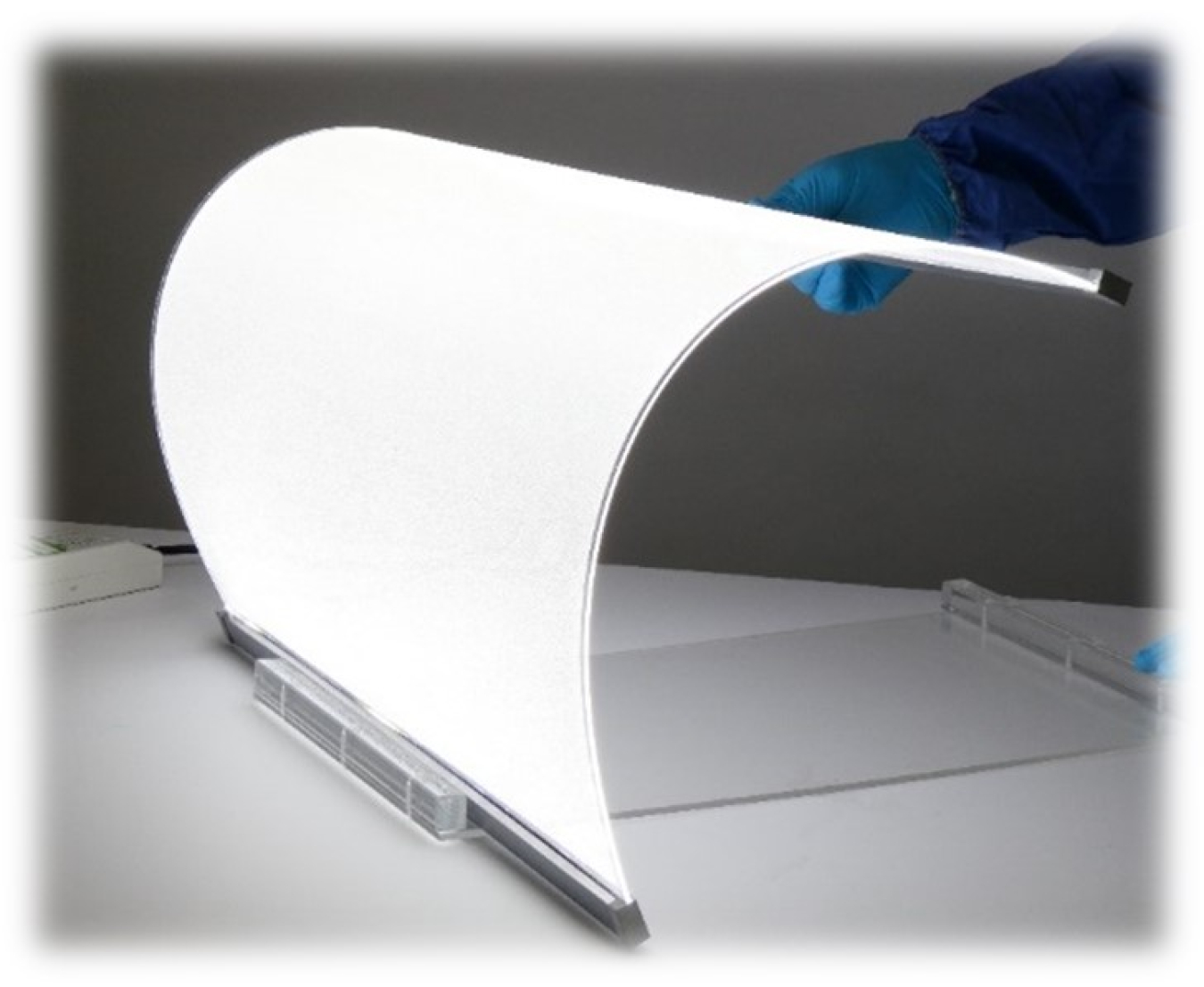

The Lighting Spotlight: Lucent Optics’ Ultra-Thin Flexible LED Lighting Panels

For nearly two decades, BTO’s Lighting Research and Development (R&D) program has led some of the most significant advancements in the lighting industry, funding 335 R&D projects that have generated 431 patents and pending applications, 346 commercially available state-of-the-art lighting products, and millions of derivative products and components. While LEDs and OLEDs are undoubtedly among the program’s most recognizable successes, other inventions like Lucent Optics’ CoreGLO™ bendable lighting panels have completely reimagined what “lightbulbs” can look like. After nearly a decade of development, Lucent Optics refined a proprietary microprinting process that allowed them to invent and affordably mass-produce, ship, and install waveguides. These waveguides – thin sheets of clear plastic – direct LED light across an entire panel that can be bent and formed into almost any size or shape. Today, manufacturers are already using CoreGLO panels – commercialized in 2020 – for smartphone, tablet, and computer displays; TVs; illuminated signs; and room lights. Thanks to these notable advances in lighting technology, the ultimate scope of future light shapes and uses are virtually limitless.

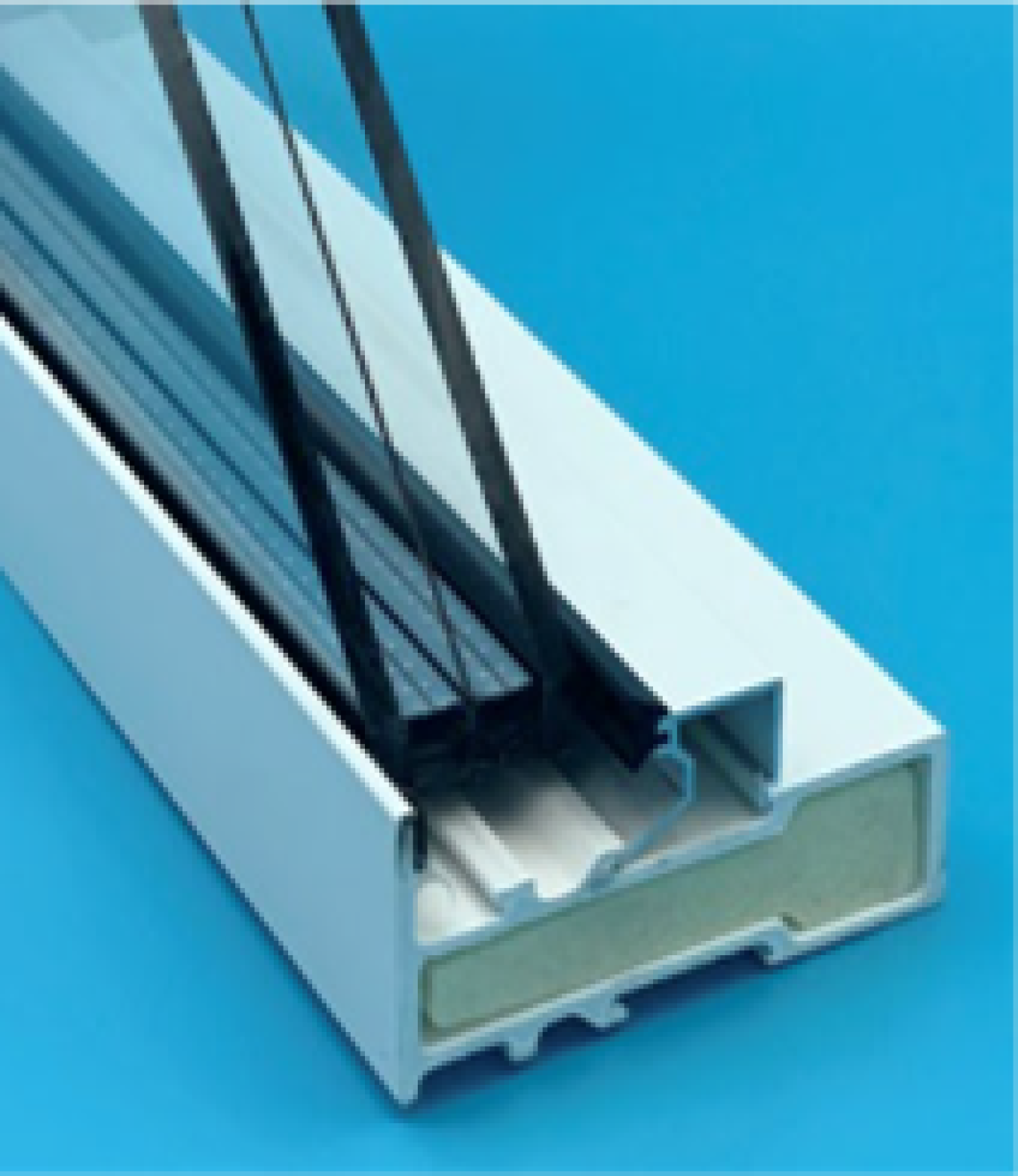

A Window into the Future: Triple Glazing with Thin Non-Structural Center Glass

Thin-glass, triple-pane windows have been the highest-performing windows on the market since they were designed and patented by the Lawrence Berkeley National Laboratory in 1989. But previous generations of “thin triples” were too costly for renovators or builders to use, as large sheets of very thin glass and other necessary materials were largely unavailable until the manufacture of flat-screen TVs and phones established an abundant source of thin glass. Now, “thin-triples” – which are about twice as effective as the highest-end single- or double-paned low-emissivity windows – are more affordable and succeeding in the marketplace. LBNL’s Triple Glazing with Thin Non-Structural Center Glass was commercialized in 2019, and they have been working with major window manufacturers like Alpen HPP, Renewal by Andersen, and Ply Gem to develop newer generations. Understanding the energy-efficiency benefits of thin-triples, leading utilities like PG&E and Eversource are also offering rebates to customers who install them.

Cool, New Air Conditioners: Next Generation Rooftop Unit

Rooftop air conditioning units, or RTUs, cool over half of the space in America’s 5.9 commercial buildings and use so much energy they account for 1.3% of primary energy use in the United States. To address this, Oak Ridge National Laboratory (ORNL) partnered with Trane, Emerson and Ebm-papst to develop a more energy-efficient, next-generation RTU that meets the latest Integrated Energy Efficiency Ratio (IEER) standards. What resulted was a Next-Generation RTU that boosted cooling capacity from 13 to 20 tons and its IEER from 17.9 to 22.0. They accomplished this by making four changes. They reconfigured the RTU’s vapor compression system with two, two-stage compressors and Emerson’s single-speed compressor; replaced the indoor blower fan with Ebm-papst’s high-efficiency backward-curved fans; introduced a submerged subcooler to recover and reuse chilled air that’s traditionally lost; and replaced the traditional refrigerant R-410A with R-452B, a tweak that increased the RTU’s efficiency by an additional 5% in addition to the environmental benefits from refrigerants with low global warming potential (GWP). This Next-Generation Rooftop Unit was commercialized in 2018, and the concept of trio-compressors for high-efficiency RTUs have been used in a variety of products on the commercial market today.

Energy-Producing Walls: Integrated Concentrating (IC) Solar Envelope

Windows, walls, and roofs have always sheltered us from the elements and kept cool or warm air from escaping, but what if they could make energy at the same time? That’s exactly what DOE explored and developed: an energy-efficient façade that doubles as a concentrating solar plant. The Integrated Concentrating Solar Envelope (IC Solar), which was commercialized in 2020 and licensed by HeliOptix, LLC, encases tracking concentrator photovoltaics within a deep-mullion fenestration unit that can be used in building façades, clerestories, roofs, and atriums, to enhance daylighting, reduce solar gains, generate electricity, and control heat transfer. This unique technology lets enough sunlight through to illuminate rooms but redirects the rest onto small (1cm2) multijunction photovoltaic (PV) cells to generate electricity. Each PV cell is bonded to a coolant loop with heat exchangers that captures, collects, and transforms any remaining solar energy into heat that can be vented or reused for other energy services in the building, like processing hot water or dehumidifying the air. To see one, visit the United Nations' Ecological Living Module demonstration in New York City.

Tackling an Emerging Challenge with Data Center Toolkits

Data centers currently use about 2% of U.S. electricity, but that share is growing as more of America’s economy moves online and cloud computing needs continue to increase. Half of this electricity is used for cooling alone, as IT equipment generates notable amounts of heat. Because IT racks aren’t humans who must be kept comfortable, data centers only cool their air intakes, not their exhausts, leading to imbalanced “hot aisles” and “cold aisles.” The airflows created from the different temperatures can interfere with the cooling process. To address this, DOE developed the Data Center Toolkit, an open-source modeling platform that can be used to optimally manage data-center cooling and airflow simultaneously. In tests, the project team used Data Center Toolkit’s recommendations to reduce a Florida-based data center’s energy use by 53%, and by 74% in a Massachusetts-based one, well above predictions of 30% savings. Schneider Electric used this technology to develop EcoStruxure™ IT Advisor CFD, a cloud-based asset and planning software that enables data center managers to reduce operation expenses and plan for uptime, with analytics to facilitate capacity planning decisions. The technology was commercialized in 2020, and the IT Advisor CFD software was launched in 2021.

These five technologies are just a sampling of the commercial successes BTO’s research has enabled in the past five years. To learn about all of them, along with how BTO works to improve building performance and measure its progress, read the report.