OVERVIEW

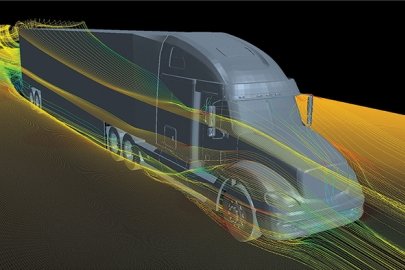

The national laboratories of the U.S. Department of Energy (DOE) possess world-class expertise in high-performance computing (HPC) and operate some of the world’s most powerful computers. Complex computational studies can yield valuable insights and improve technology across scientific disciplines. Leveraging DOE’s HPC resources can expedite the development of energy-efficient manufacturing processes across U.S. industry—saving energy, reducing emissions, boosting competitiveness, and building global technology leadership.

FOR ADDITIONAL INFORMATION, PLEASE CONTACT:

Paul Syers

Technology Manager

U.S. Department of Energy

Advanced Materials and Manufacturing Office

Email: paul.syers@ee.doe.gov

OBJECTIVES

The DOE launched the High-Performance Computing for Manufacturing (HPC4Mfg) program in 2015 to create targeted partnerships between U.S. manufacturers and the national laboratories. Under this program, competitively selected projects apply modeling, simulation, and data analysis to industrial processes and products to lower production costs and shorten the time to market. The aim is to advance future technology investments by optimizing designs, predicting performance, and reducing the number of testing cycles during development. In each case, the industry partner identifies the manufacturing challenge to ensure that the process or product will have direct commercial impacts.

This program is designed to foster an open exchange of best practices and know-how, breaking down communication barriers between world-class researchers, equipment suppliers, and manufacturing companies. Computer scientists at the national laboratories will benefit by expanding software codes for application to diverse problem sets. In the short term, industry benefits by reducing investment risk and improving energy efficiency. In the longer term, the U.S. manufacturing sector will increasingly turn to HPC modeling and simulation as trusted tools to accelerate innovation and achieve significant energy and cost savings.